Non-invasive online detection method and system for rotor broken-bar fault of three-phase cage type asynchronous motor

A non-invasive technology for broken rotor bars, applied in the field of detection, which can solve problems such as misjudgment, lack of research on characteristic spectral lines, and lack of practical and effective solutions to signal interference problems, achieving the effect of simple operation and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

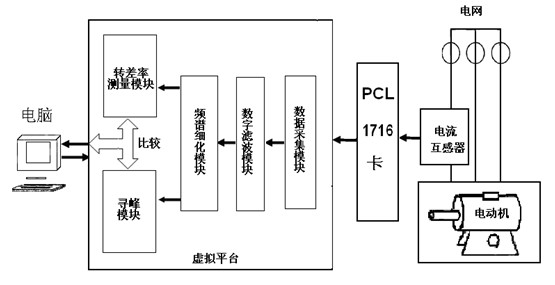

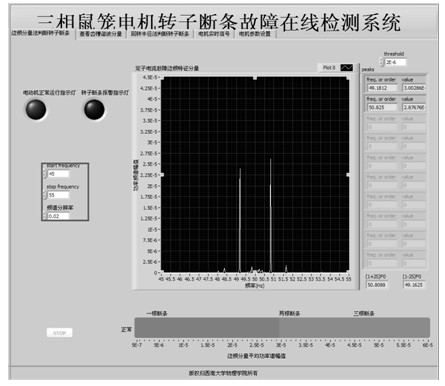

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

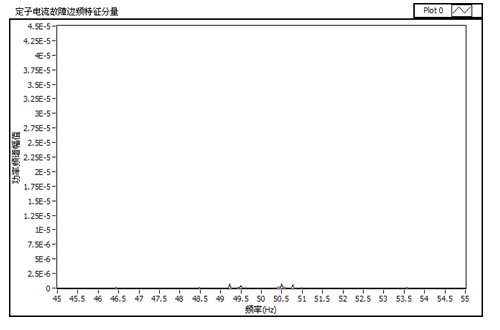

[0027] Ideally, the stator current frequency of an asynchronous motor should be a single power supply frequency. However, when the rotor has a broken bar fault, the stator current will appear at a frequency of (1±2s)f 0 side frequency components. The analysis process can be reasoned and analyzed by the following expression.

[0028] When the motor is running, the fundamental wave of the three-phase winding of the stator to form a magnetomotive force can be expressed by the following formula:

[0029] F 1 ( t , θ ) = 3 2 πp k s N 1 I 1 sin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com