Plasmon enhancement type solar cell with intermediate bands and photoelectric conversion film material of solar cell

A plasmon-enhanced, solar cell technology, applied in nanotechnology, circuits, electrical components, etc. for materials and surface science, which can solve problems such as lack of solar cells, low conversion efficiency, cell stability, and complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] The present invention also provides the preparation method of described photoelectric conversion film material, it comprises the following steps:

[0089] i), providing a photoelectric conversion layer with an intermediate energy band;

[0090] ii), building a nano-metal structure layer on the photoelectric conversion layer with intermediate energy band by photolithography or self-assembly method.

[0091] In a specific embodiment, the preparation method of photoelectric conversion thin film material is as follows:

[0092] a), using unequal or non-compensated n-p co-doped TiO 2 Materials to realize functional thin film materials with intermediate energy bands (photoelectric conversion layers with intermediate energy bands);

[0093] b), building nano-metal structures on intermediate energy band materials by photolithography or self-assembly;

[0094] Wherein, in step a), the unequal n-p co-doping method can adopt but not limited to methods such as vapor deposition o...

Embodiment

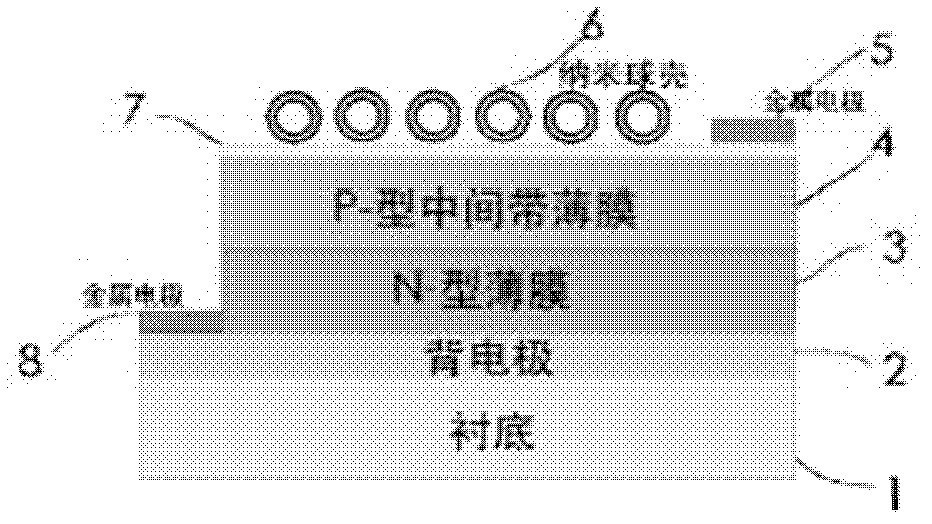

[0135] Implementation details of the invention will now be described, including exemplary aspects and implementation examples of the invention. see figure 1 As indicated in , the associated numerals and the following description set forth the main features of the exemplary embodiments. Additionally, there is no intention in the legends to depict every feature of actual embodiments or to depict relative dimensions of elements, and the drawings are not drawn to scale.

[0136] The basic concept of manufacturing the described plasmonic enhanced intermediate band solar cells is to sequentially grow figure 1 Materials of construction for each layer shown. That is, epitaxially grow or vapor-deposit the back electrode 2 on the substrate, and then manufacture a complementary thin film, that is, an N-type thin film material (such as TiO 2 or ZnO), P-type intermediate zone film 4 and nano-metal structure 6.

[0137] Appropriate reaction temperature and time are preferred, and approp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com