Hybrid glass fiber diaphragm for storage battery as well as method and system for manufacturing hybrid glass fiber diaphragm

A technology of glass fiber and manufacturing method, which is applied in the diaphragm manufacturing method and system, and in the field of hybrid glass fiber battery diaphragm, which can solve the problem of improving the tensile strength, porosity, and tensile strength of the ultrafine glass fiber diaphragm, which cannot meet the quality of the battery and other issues to achieve the effect of improving tensile strength and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

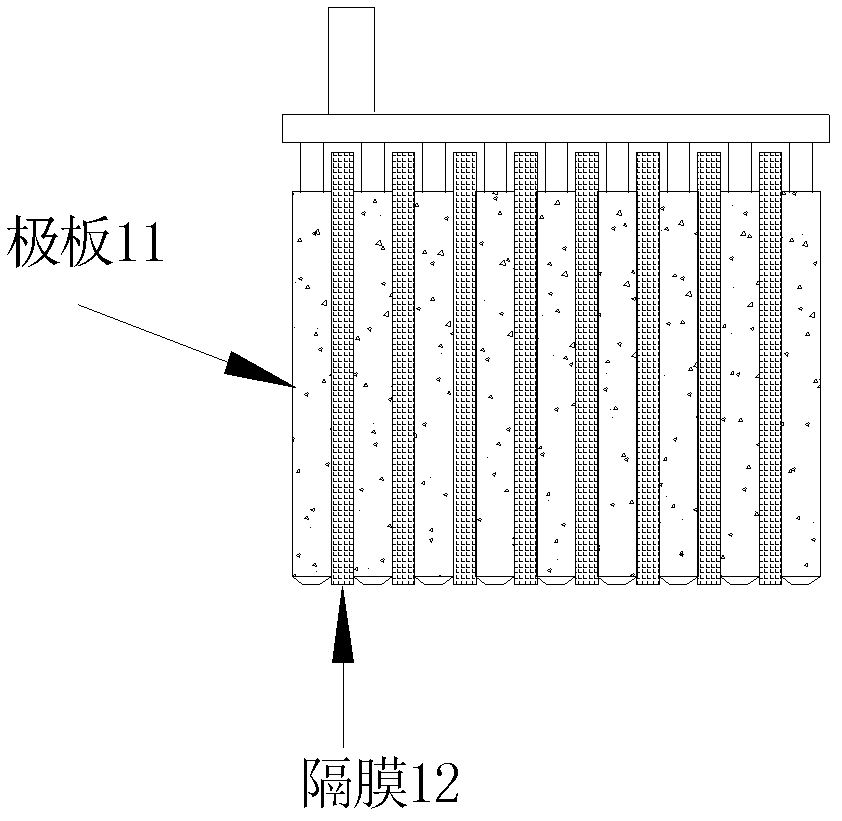

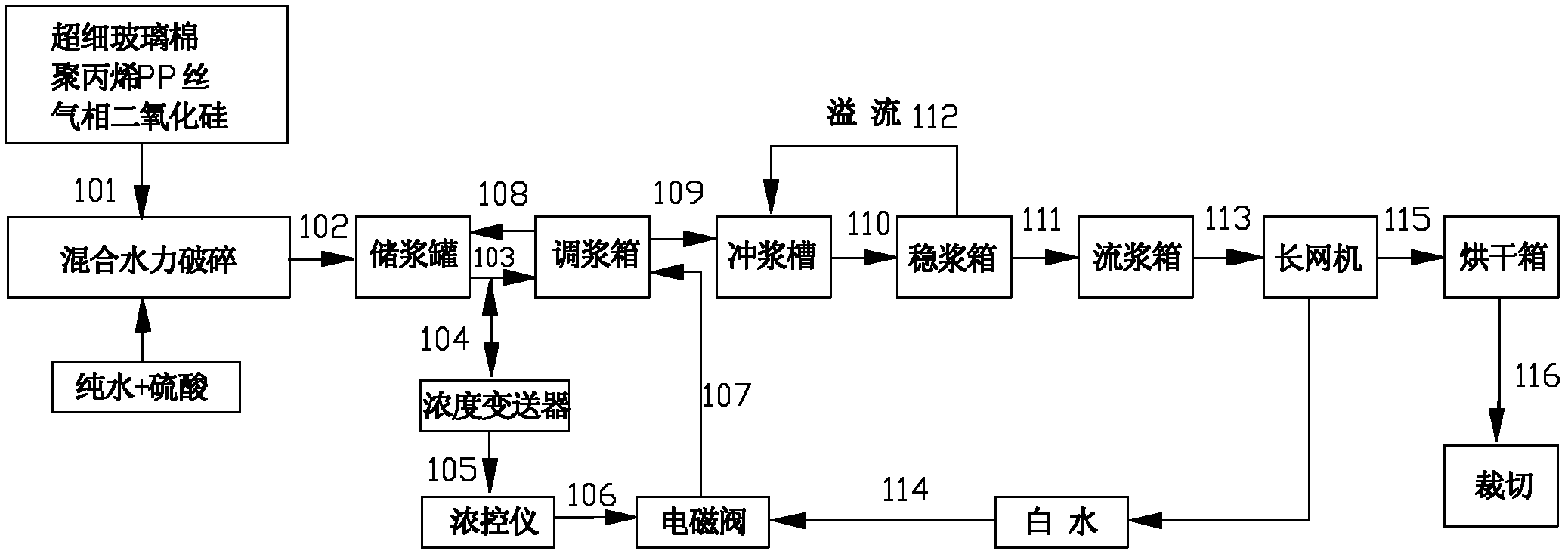

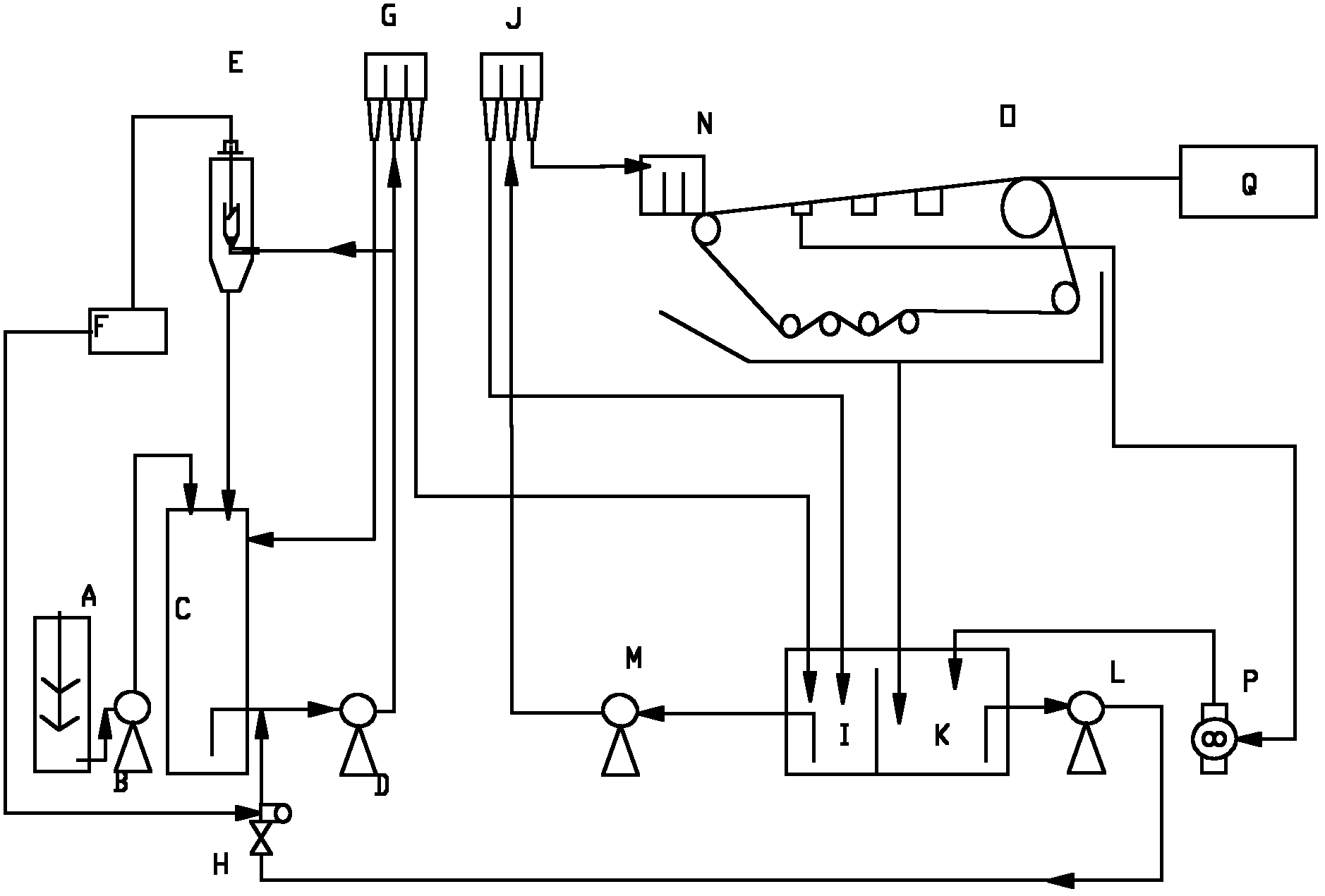

[0045] The invention discloses a mixed glass fiber accumulator diaphragm and a method for manufacturing the diaphragm. The constituent components of the mixed glass fiber accumulator diaphragm include superfine glass fiber cotton, hydrophobic fiber material and gas phase silicon dioxide. When manufacturing the diaphragm, the discharge capacity of the battery is improved by adding hydrophobic fiber substances to the hydrophilic glass fiber, and the tensile strength and liquid absorption of the diaphragm are enhanced, thereby improving the cycle life of the battery. By adding an appropriate amount of fumed silicon dioxide, the puncture resistance and tensile strength of the separator in dry and wet states are increased, and the production efficiency and performance of the battery are improved at the same time.

[0046] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com