Single-machine multi-drive and multi-winding motor system

A multi-winding, multi-drive technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., to achieve high precision, good anti-interference performance, good follow-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The content of the present invention will be further described below in conjunction with the accompanying drawings, but the practical application structure of the present invention is not limited to the following embodiments.

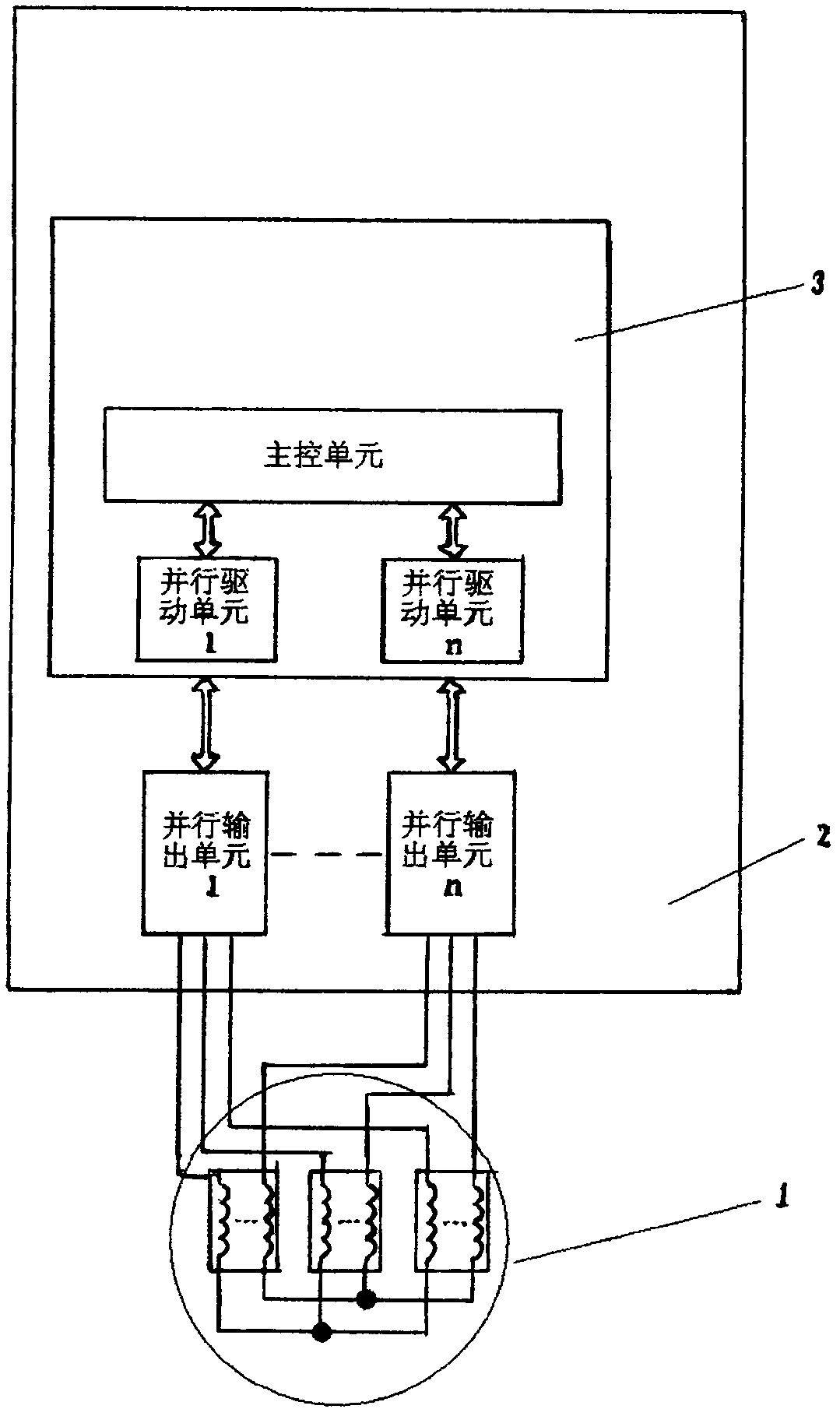

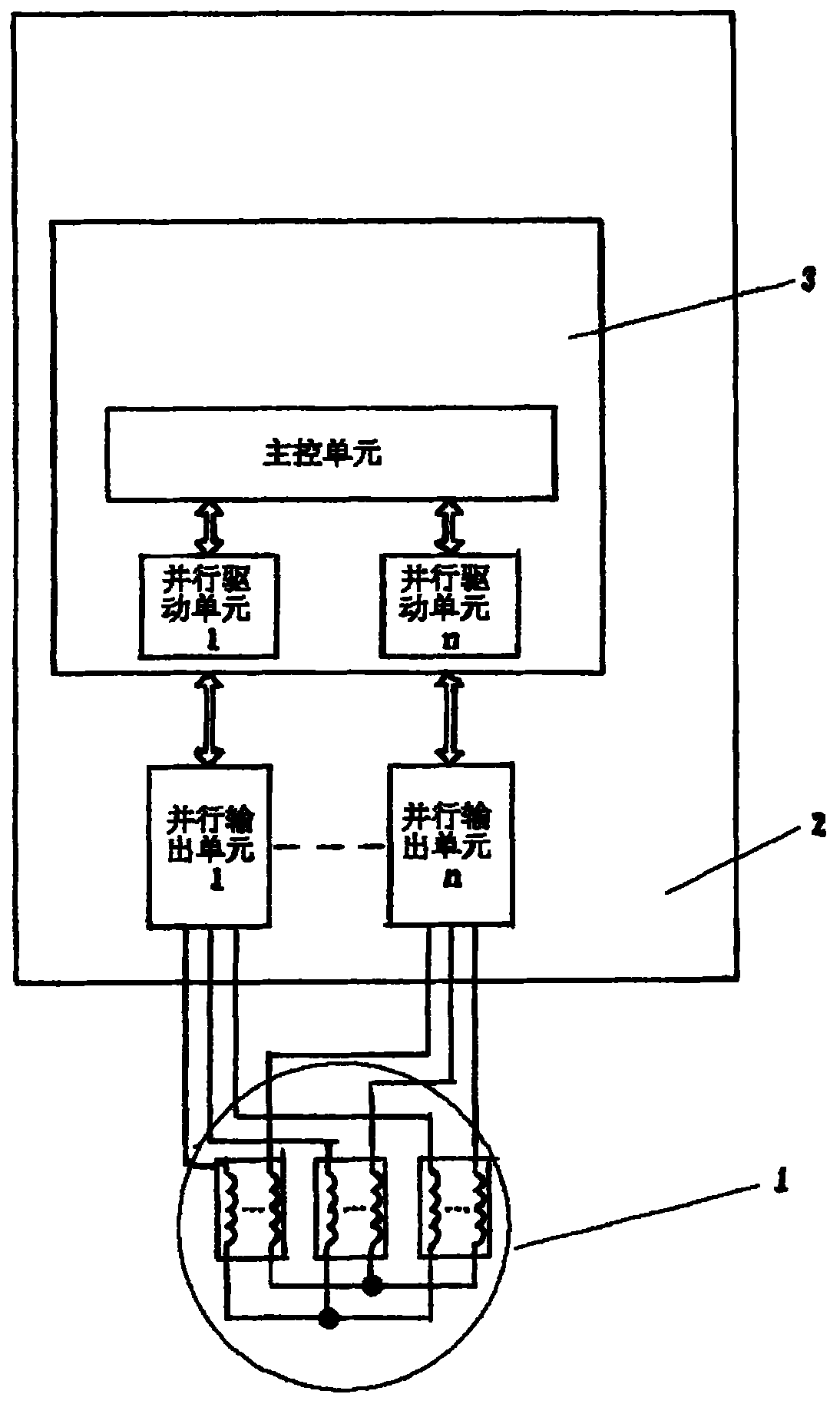

[0018] Referring to the accompanying drawings, the stand-alone multi-drive multi-winding motor system of the present invention is composed of a parallel multi-winding motor 1 and a driver 2. The driver 2 includes a core controller main board 3 and no less than two independent circuits. Parallel drive units.

[0019] The parallel multi-winding motor in the accompanying drawings of the present invention takes a three-phase asynchronous motor as an example. There are multiple sets of independently working windings arranged in parallel on the stator of the motor. The power connection method of a single winding is consistent with that of a single winding motor. The parallel windings of the motor work independently, and their power supply terminals are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com