Piston-chamber hydro-gravity engine

A piston chamber and engine technology, applied in the direction of reciprocating piston engines, engine components, variable displacement engines, etc., can solve problems such as insufficient production, unreasonable safety standards, unreliable economy, etc., and achieve the goal of solving environmental and energy problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

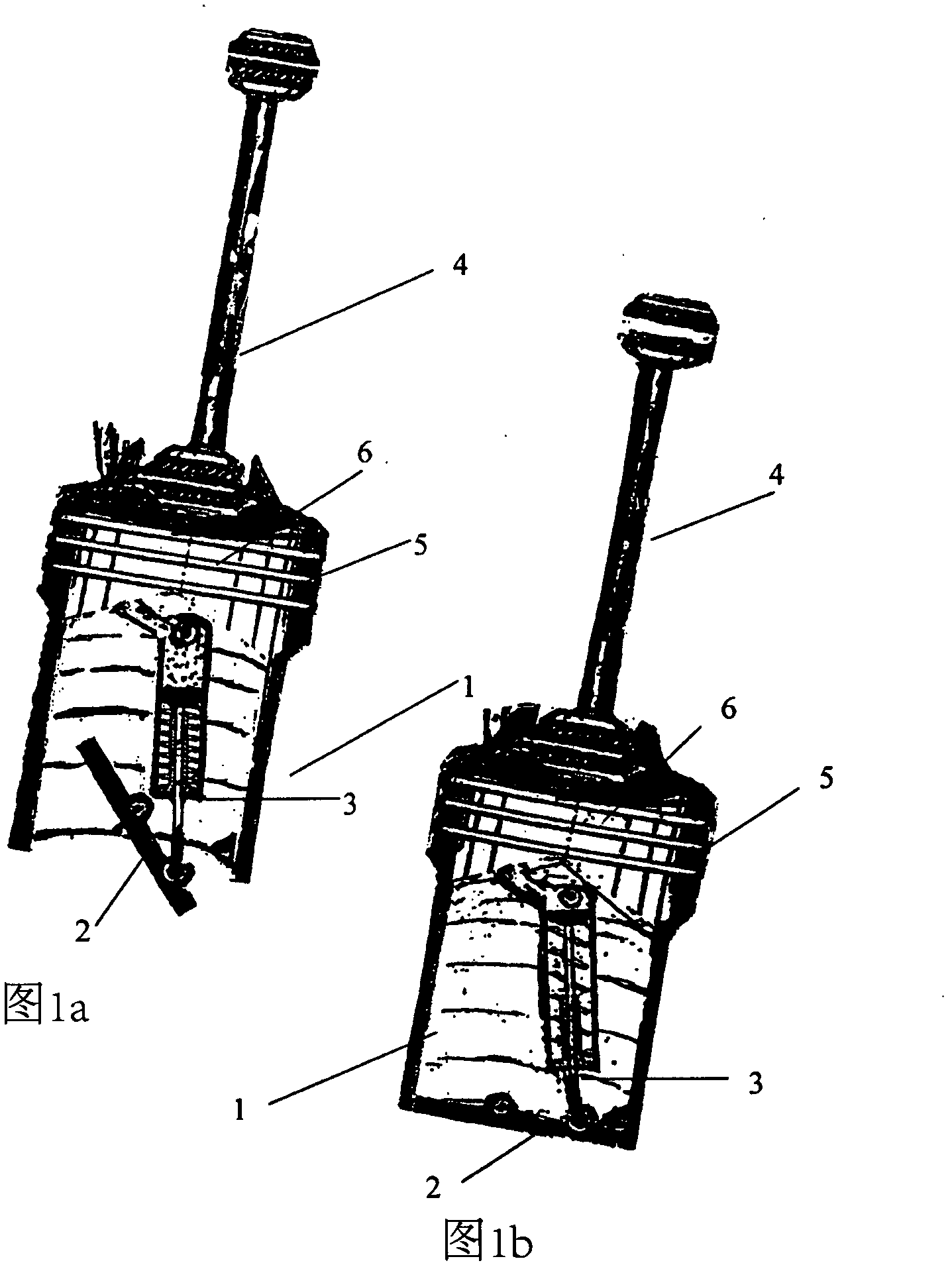

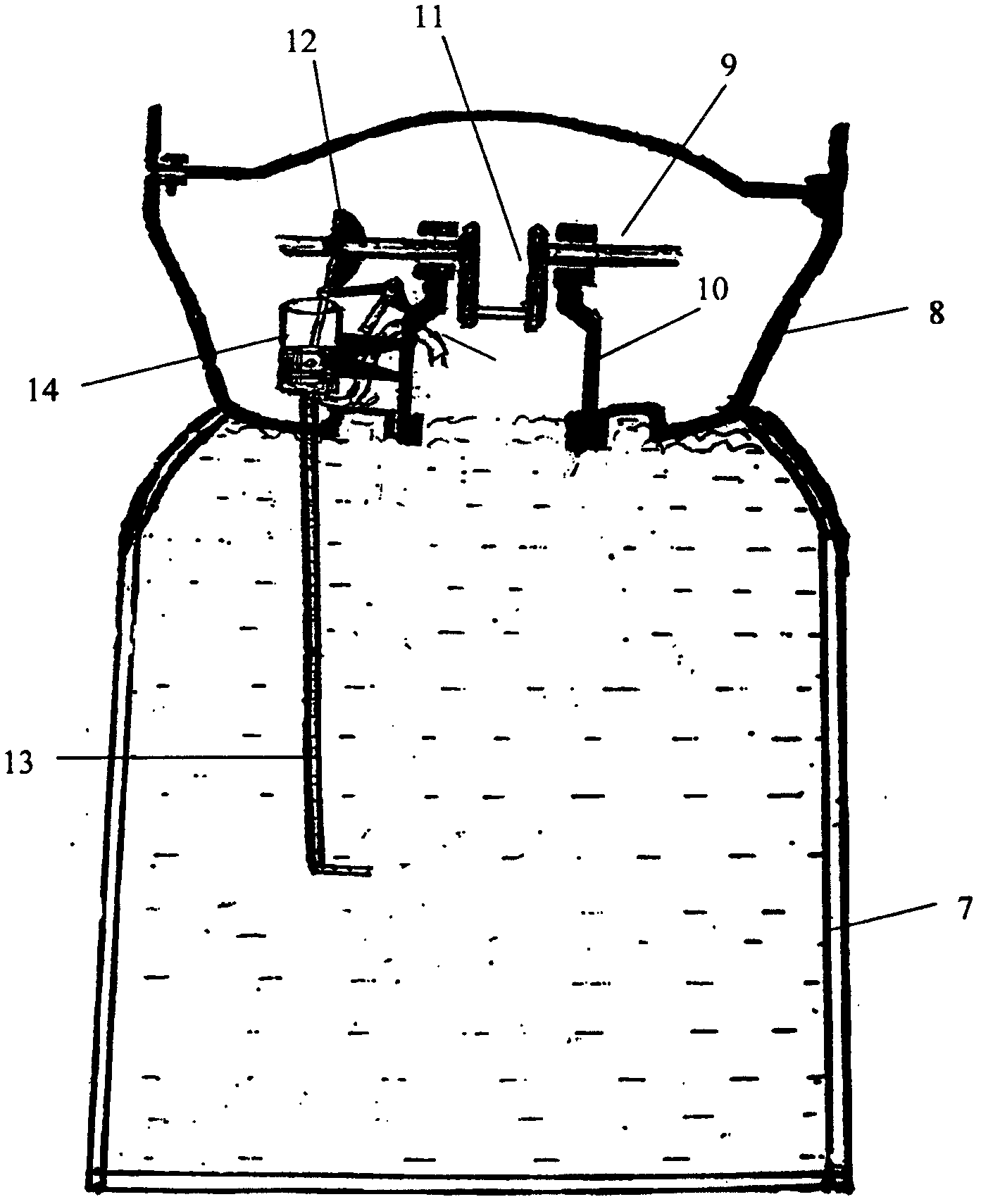

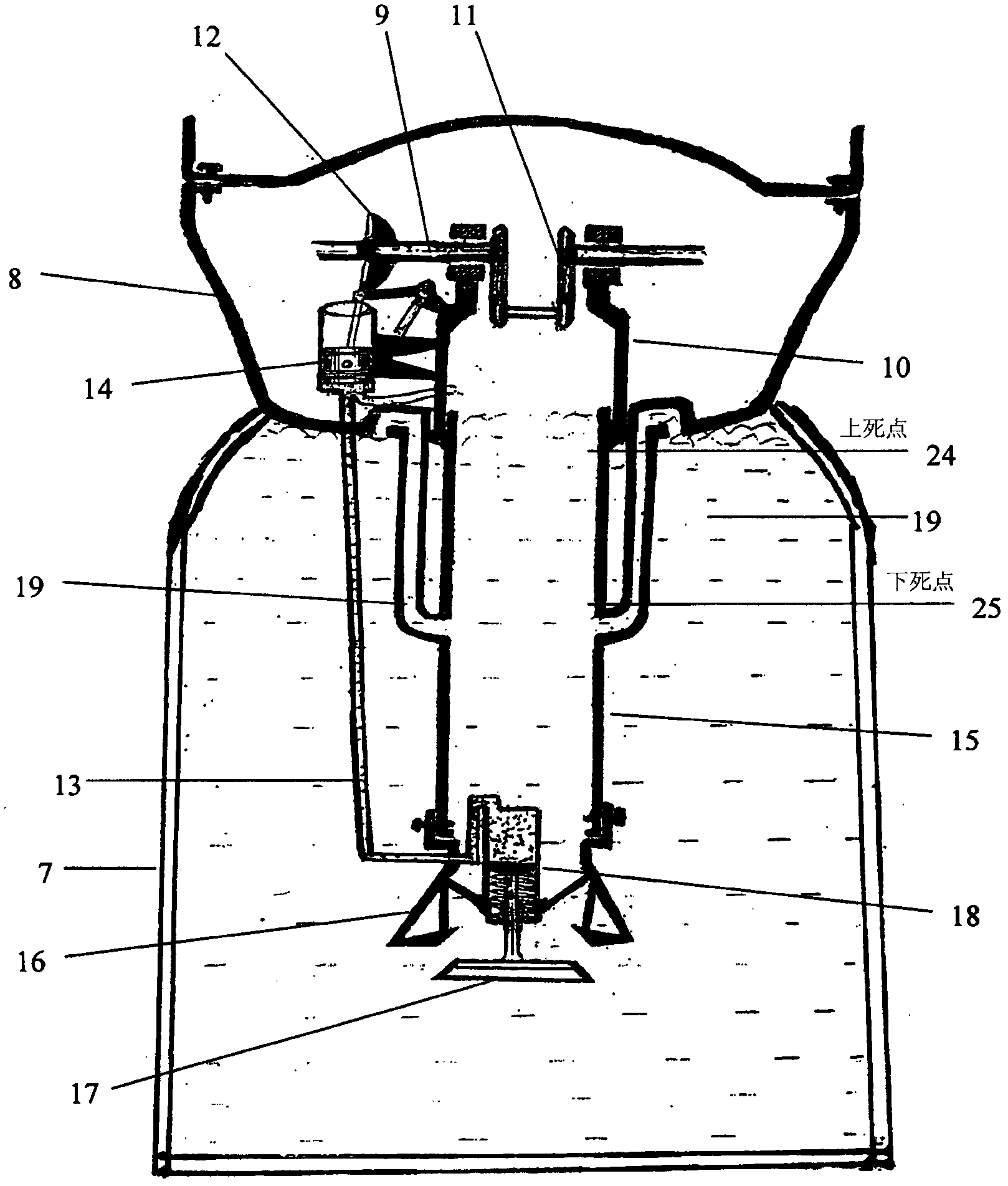

[0100] The detailed description of the present invention and the accompanying drawings describe the working mode of the technical design of the piston chamber liquid gravity engine determined according to the method currently invented, and are only used for explaining examples rather than limiting the present invention. In particular, the description and the accompanying drawings Diagrams are used to show the concept of the method and the mode of design of this piston chamber liquid gravity engine technology, how it utilizes the modes of gravitational liquid static and liquid gravity forces and how the liquid gravity forces are converted to a mechanically reproducible engine that can be applied in various ways Active energy, rather than limiting the method and the piston chamber liquid gravity engine system designed using the method technology.

[0101] image 3 A liquid container (7) is shown filled with a hermetically isolated liquid substance.

[0102] The outer sealing su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com