Application method of ash bars in papermaking-method reconstituted tobaccos

A technology of reconstituted tobacco leaves and application methods, which is applied in the fields of application, tobacco, and tobacco preparation, can solve the problems of insufficient supply of raw materials for tobacco leaf fragments, and achieve the effects of high usability, reduced raw material costs, and high tobacco aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

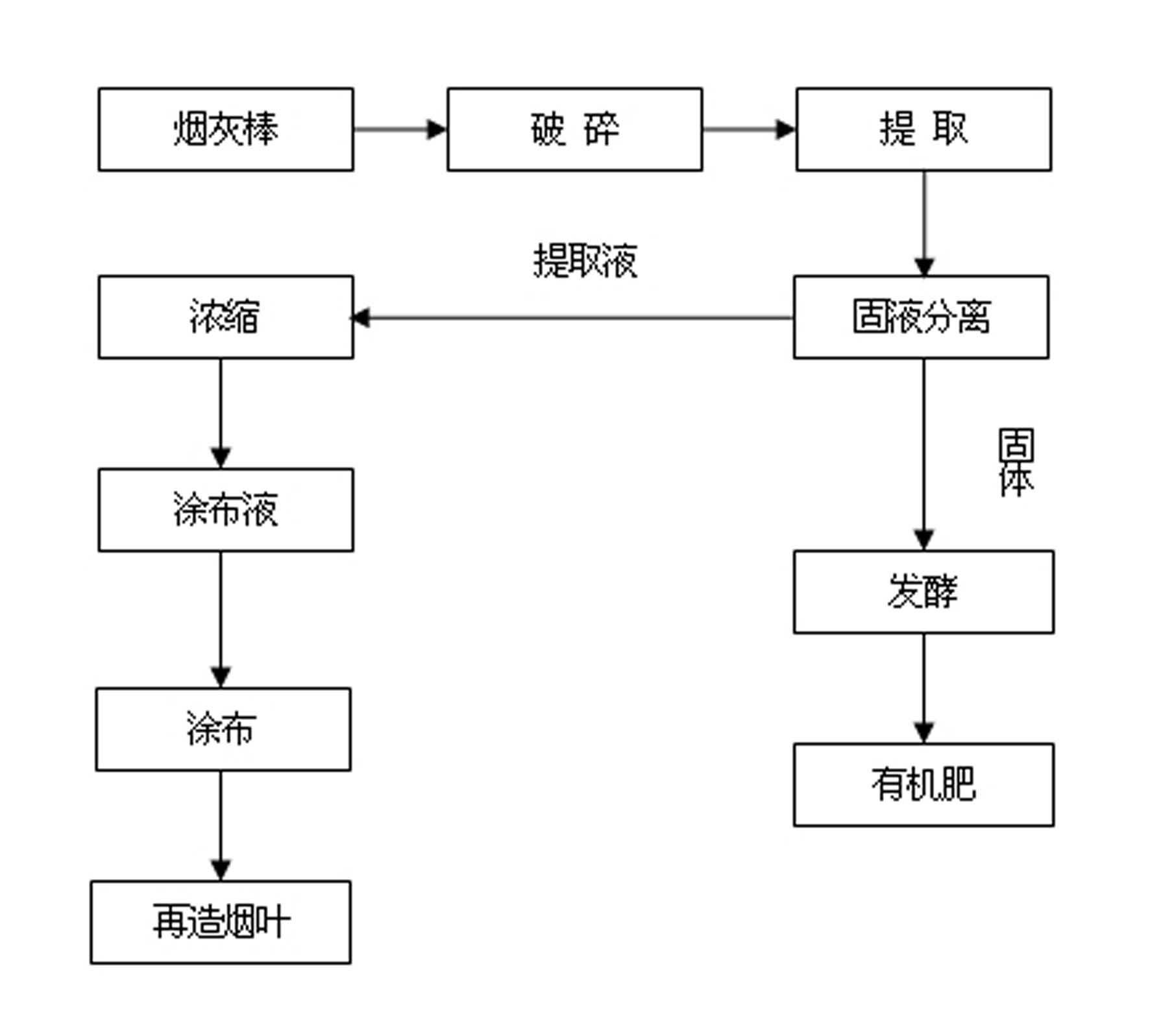

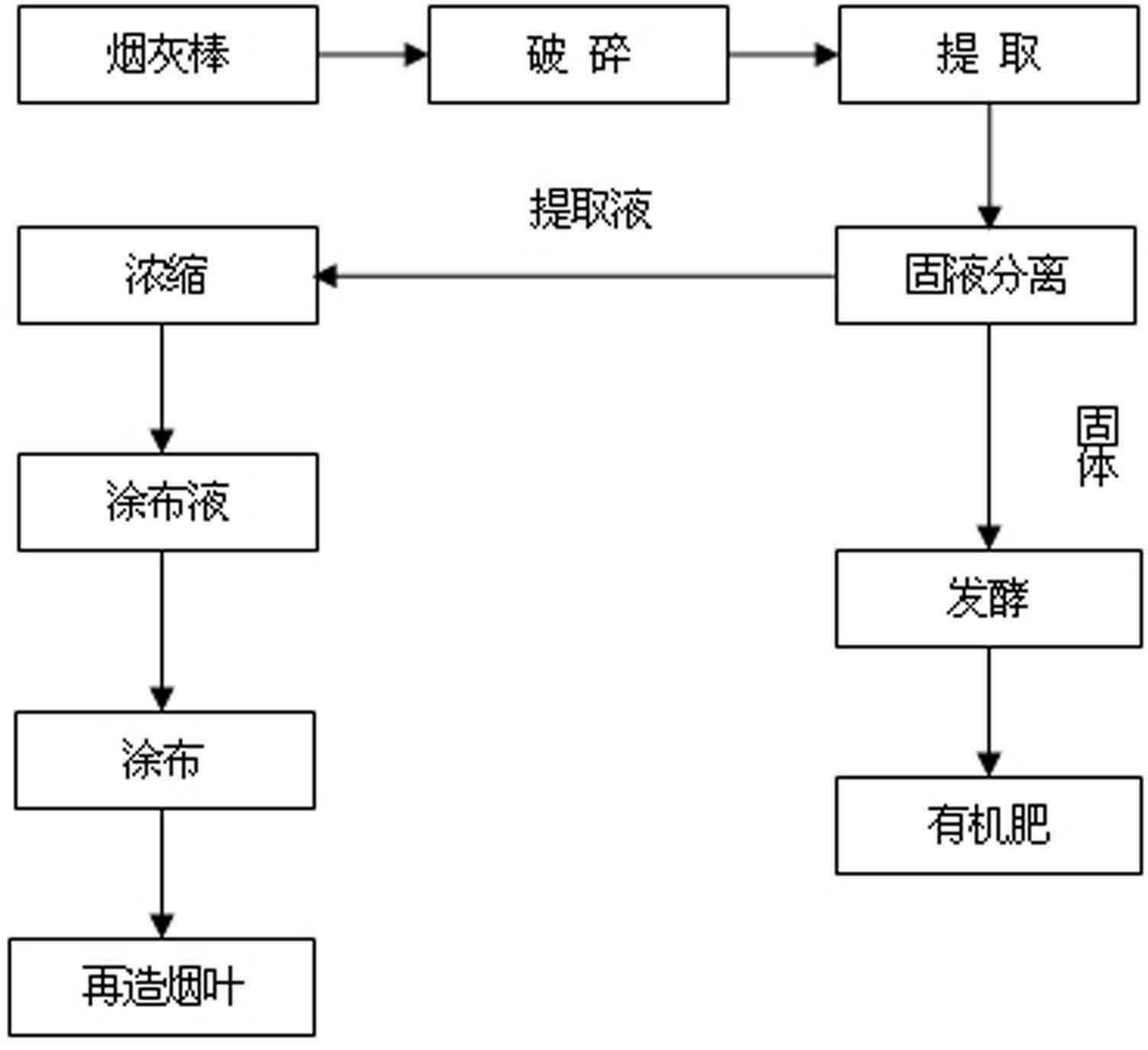

Image

Examples

Embodiment 1

[0023] ① Use the waste ash sticks generated in the dust removal section during the cigarette production process as raw materials;

[0024] ② Feed the raw material into the jaw crusher and crush it until the diameter is less than 10mm;

[0025] ③ Send the crushed raw materials to the extraction tank, use 75°C water as solvent for extraction, control the solid-liquid ratio to 1:5 during extraction, extract at 65°C, and extract for 30 minutes;

[0026] ④ The extracted material is pumped to a vibrating screen for filtration and then used to centrifuge at a speed of 6000 rpm for solid-liquid separation;

[0027] ⑤ After the separated liquid is vacuum-low-temperature concentrated to a concentration of 45%, it is added to the coating liquid at a ratio of 10% for coating to produce reconstituted tobacco leaves; the separated solid is fermented and used as an organic fertilizer.

Embodiment 2

[0029] ① Use the waste ash sticks generated in the dust removal section during the cigarette production process as raw materials;

[0030] ② Feed the raw material into the jaw crusher and crush it until the diameter is less than 10mm;

[0031] ③Send the crushed raw materials to the extraction tank, use 90°C water as the solvent for extraction, the solid-liquid ratio is controlled at 1:3 during extraction, the extraction temperature is 80°C, and the extraction time is 20 minutes;

[0032] ④ The extracted material is pumped to a vibrating screen for filtration and then used to a centrifuge for solid-liquid separation;

[0033] ⑤ After the separated liquid is vacuum-low-temperature concentrated to a concentration of 30%, it is added to the coating liquid at a ratio of 30% for coating to produce reconstituted tobacco leaves; the separated solid is fermented and used as an organic fertilizer.

Embodiment 3

[0035] ① Use the waste ash sticks generated in the dust removal section during the cigarette production process as raw materials;

[0036] ② Feed the raw material into the jaw crusher and crush it until the diameter is less than 10mm;

[0037] ③Send the crushed raw materials to the extraction tank, and use 50°C water as the solvent for extraction, the solid-liquid ratio is controlled at 1:8 during extraction, the extraction temperature is 60°C, and the extraction time is 60 minutes;

[0038] ④ The extracted material is pumped to a vibrating screen for filtration and then used to a centrifuge for solid-liquid separation;

[0039] ⑤ After the separated liquid is vacuum-low-temperature concentrated to a concentration of 60%, it is added to the coating liquid at a ratio of 5% for coating to produce reconstituted tobacco leaves; the separated solid is fermented and used as an organic fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com