Method for processing and forming pipe fitting connection end of motorcycle frame

A connection end, processing and forming technology, applied in the field of processing and forming of the connection end of motorcycle frame pipe fittings, can solve problems such as loose fit, inconsistent gap between upper and lower incisions, and inability to punch out, so as to improve the tightness of fit , Improve the connection strength, improve the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

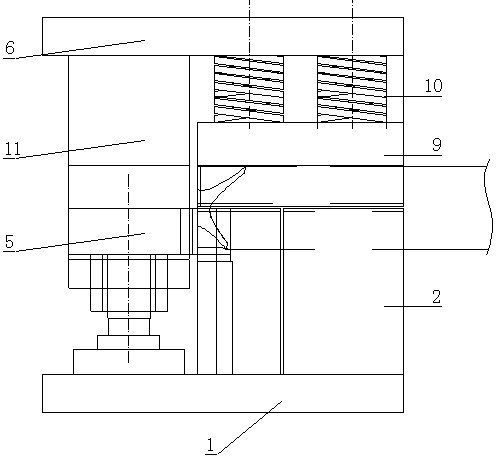

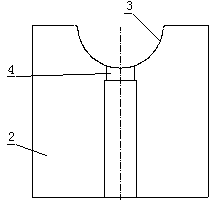

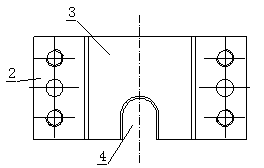

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings during specific implementation.

[0024] A method for processing and forming a connecting end of a motorcycle frame pipe fitting, comprising the following steps: a. pre-processing a notch, that is, machining a notch at the connecting end of the pipe fitting, and the depth of the notch is not less than the depth of the arc-shaped groove to be processed ; b. Use the mold to process the arc groove, position the pipe to be processed, and use the punching die to move from top to bottom for punching. The angle between the pipe to be processed and the direction of movement of the punching die and the pipe to be processed are welded with another pipe The joint angle is the same, the shape of the cutting edge at the lower end of the punching die is consistent with the shape of the joint of the other pipe fitting to be processed when the pipe fitting is welded, and the not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com