Puncture-resistant heavy packaging composite film and preparation thereof

A composite film, heavy packaging technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of package rupture, large fluctuation of product quality, unstable tensile strength and puncture resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with specific implementation methods, which are only for verification of the technical effects of the invention, and are not exhaustive.

[0021] Heavy packaging film technical requirements are very precise and strict:

[0022] Thickness 0.16±0.04mm

[0023] Width 550±3mm

[0024] Longitudinal tensile strength ≥ 21MPa

[0025] Transverse tensile breaking strength ≥ 21MPa

[0026] Longitudinal elongation at break ≥ 500%

[0027] Transverse elongation at break ≥ 600%

[0028] Dart impact (9) ≥ 600

[0029] The difference between the surface temperature and the indoor temperature when the film is rolled is less than 5°C

[0030] Membrane tendrils have a flat surface and neat ends.

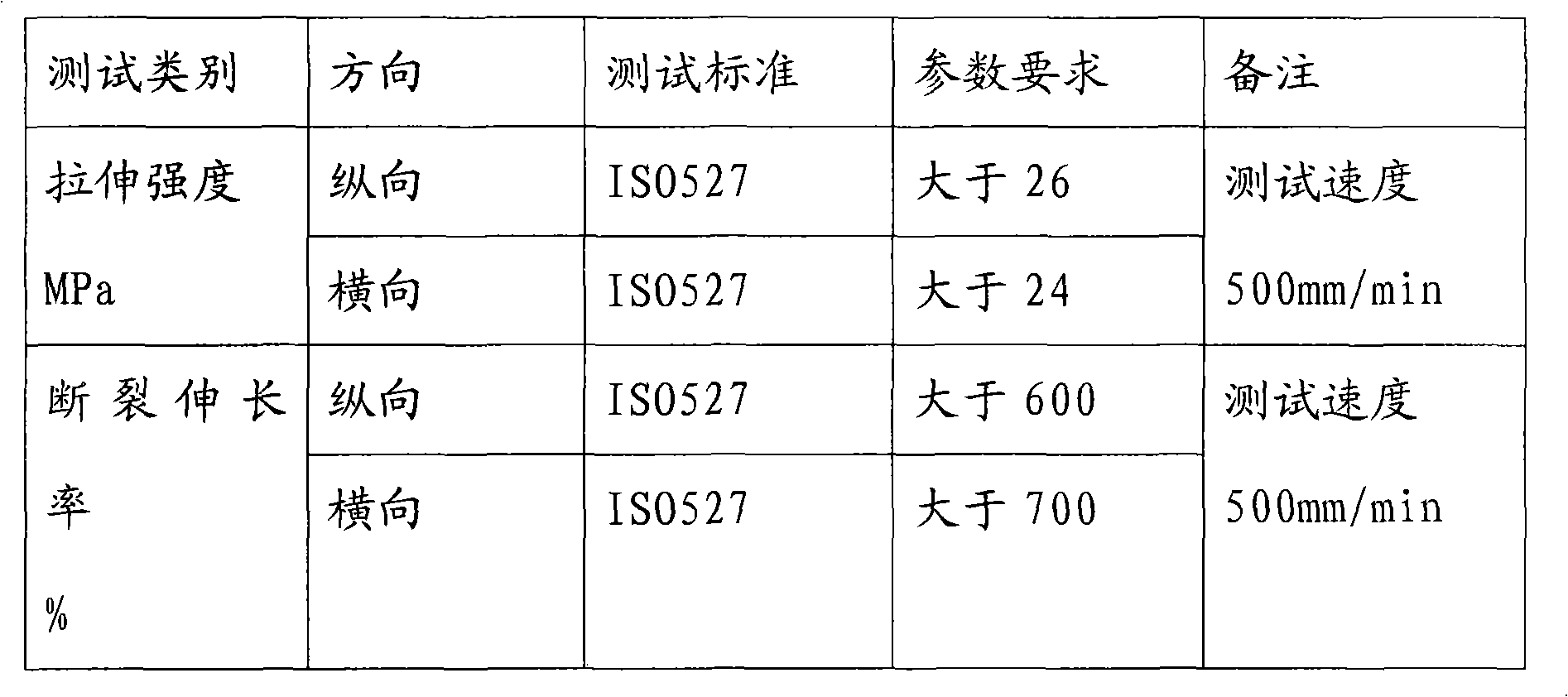

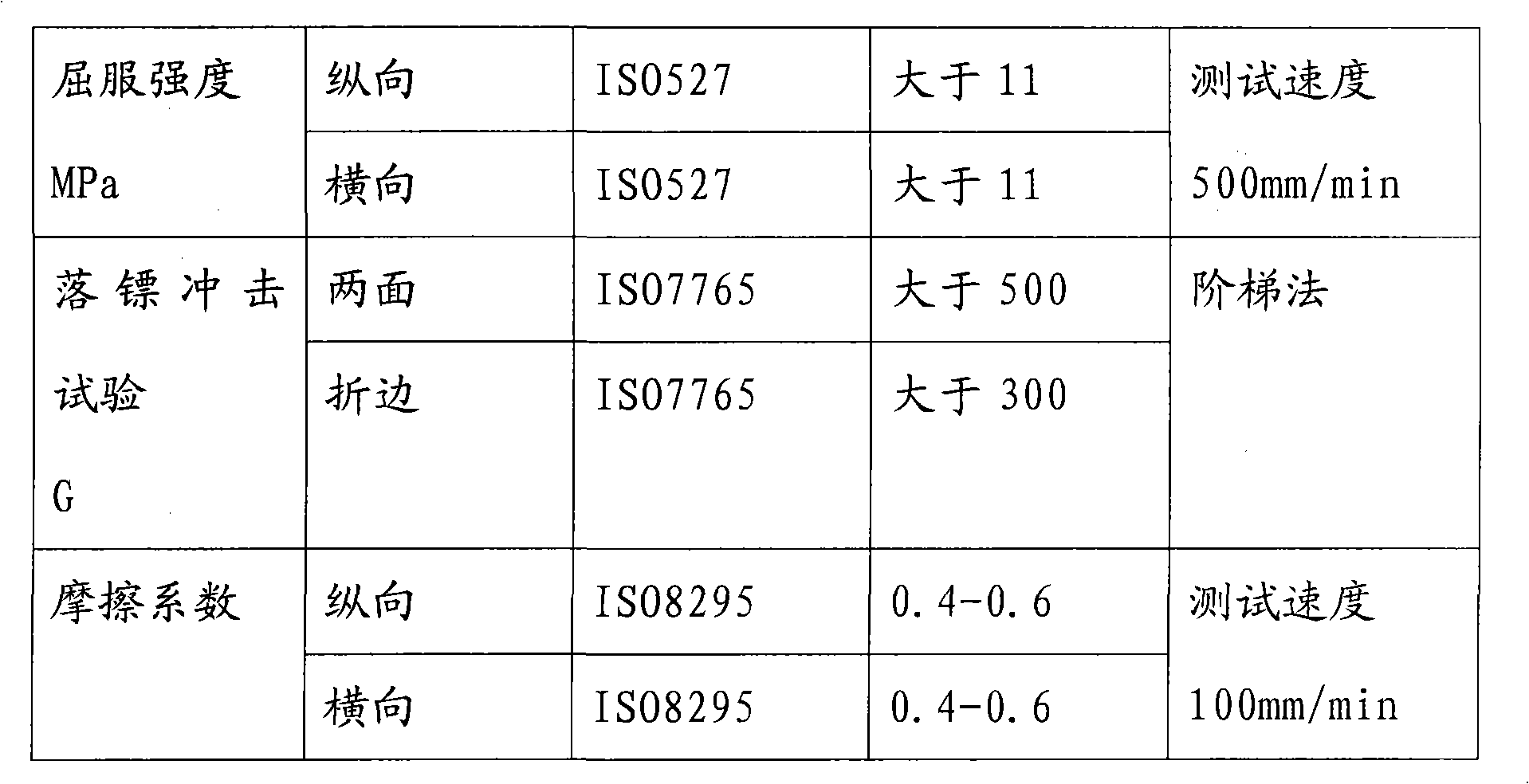

[0031] Main performance test indicators and test standards Table 1

[0032]

[0033]

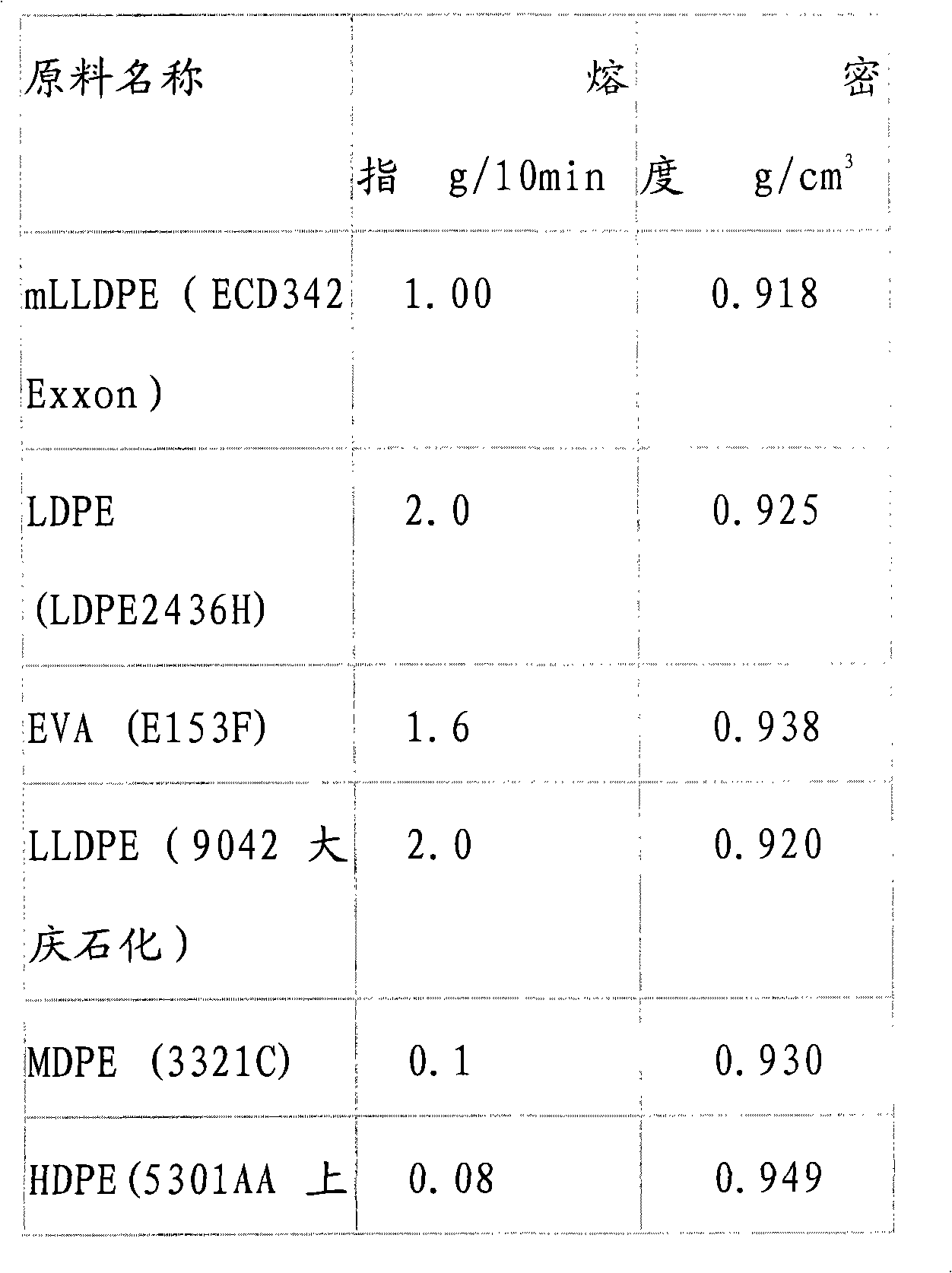

[0034] Use raw material table 2 in the embodiment

[0035]

[0036]

[0037] Use a three-layer co-extrusion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com