Post card production method and post card

A manufacturing method and technology of postcards, applied in the field of communication, can solve the problems of unattractive patterns, high processing costs, and hard texture, and achieve the effects of high commemorative collection value, short production cycle, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

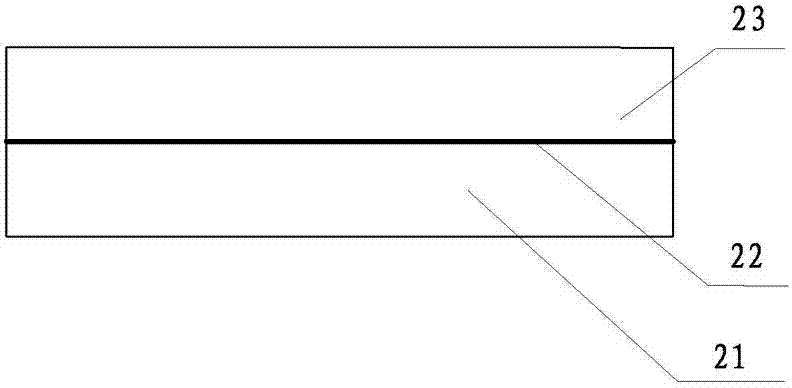

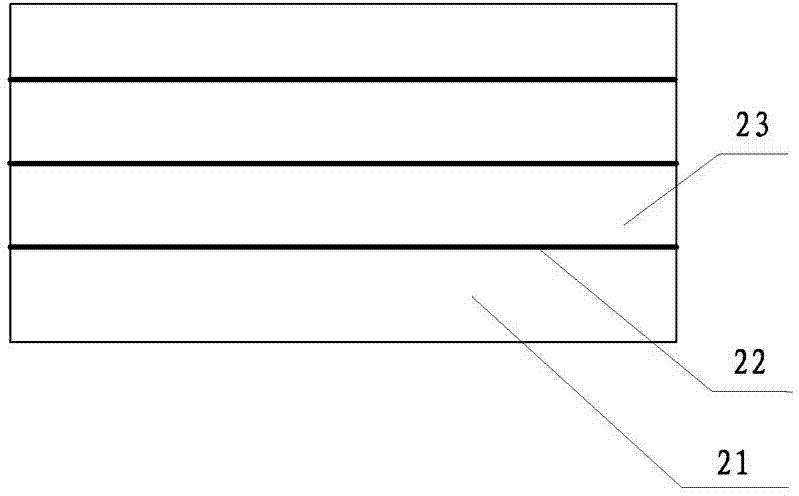

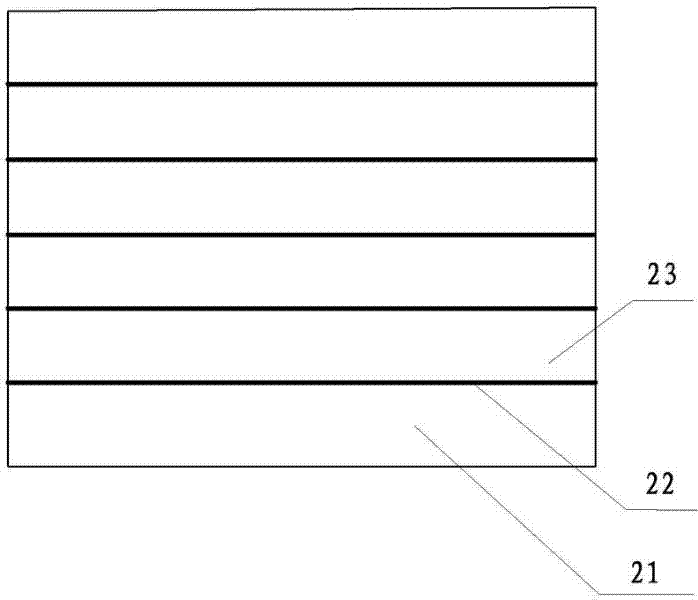

[0022] Embodiment one, such as figure 1 , figure 2 Shown, a kind of postcard comprises one deck base plate 21, is bonded one deck glue layer 22 on the described base plate 21, is also bonded one deck overlay plate 23 on the described glue layer 22, and base plate 21 and overlay plate 23 are bamboo planer The veneer is cut, the glue layer 22 is an environment-friendly glue layer, and patterns are arranged on both sides of the postcard.

[0023] Above-mentioned a kind of postcard is manufactured as follows: at first a base plate 21 is transported on the gluing machine, is coated with a layer of glue layer 22 on the base plate 21 by the gluing machine work, on the glue layer 22 superimposes superimposed plate 23 again, Then the whole is transported to the drying room for drying, and then it is taken out from the drying room and sent to the hydraulic press for heating and repressing. After repressing, it is taken out and sanded by a sander, and then cut by a cutting machine afte...

Embodiment 2

[0024] Embodiment two, such as figure 1 , figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the thickness of the base plate 21 and the superimposed plate 23 is 0.6mm, the temperature of the hydraulic press is controlled at 90°C, and the pressure is controlled at 800T / cm 2 , The number of times of repressing is controlled at 3 times.

Embodiment 3

[0025] Embodiment three, such as figure 1 , figure 2 As shown, the difference between this embodiment and Embodiments 1 and 2 is that the thickness of the base plate 21 and the superimposed plate 23 is 1.0mm, the temperature of the hydraulic press is controlled at 0°C, and the pressure is controlled at 1000T / cm 2 , the number of times of repressing is controlled at 1 time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com