Vibration damping box with adjustable rigidity and damping

A vibration damping box and damping technology, which is applied in the direction of preventing mechanical damage to containers, containers, packaging, etc., can solve the problems that the installed vibration isolator cannot be replaced, the specifications of the vibration damping box are difficult to unify, and the vibration damping box transports a single product, etc., to achieve Adjustable vibration damping performance, not easy to roll over, uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

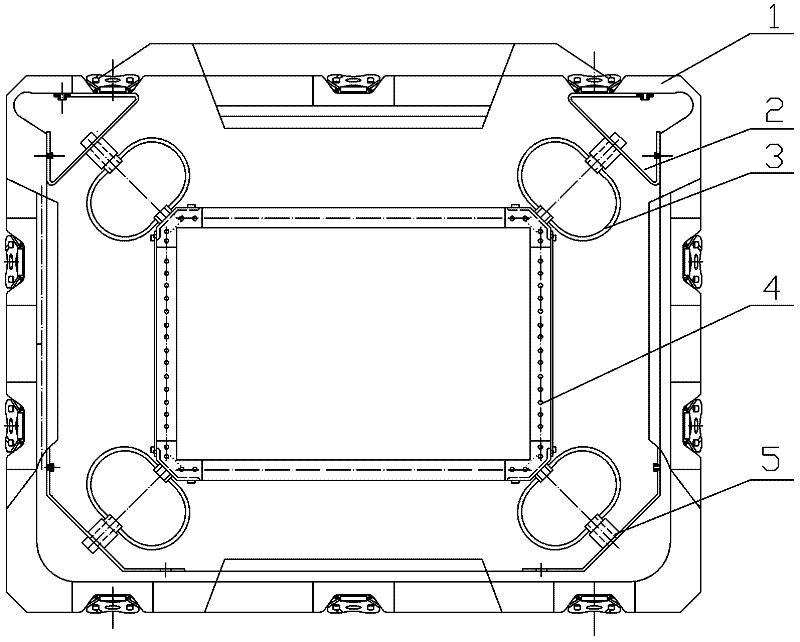

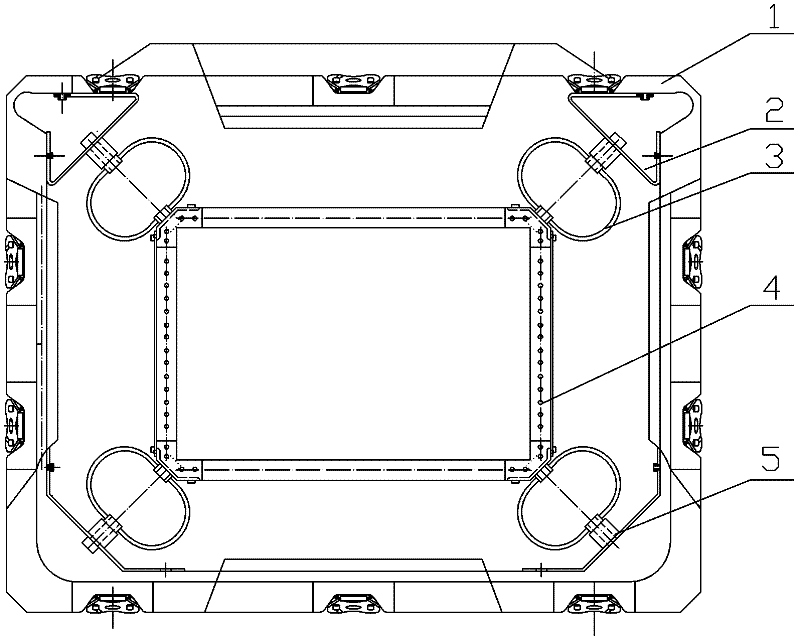

[0020] The schematic diagram of the damping box with adjustable stiffness and damping of the present invention is as follows figure 1 As shown, it includes a box body 1, a plurality of fixed supports 2 are respectively installed on the inner wall of the box body 1, a material fixing frame 4 is installed in the box body, and a plurality of material fixing holes are arranged on the material fixing frame A vibration isolator 3 is respectively installed between the material fixing frame 4 and each fixed support 2, and the acute angle between the bearing surface of each vibration isolator and the horizontal direction is 45°. Both ends of the box 1 are respectively equipped with box covers to realize sealing. Among them, the vibration isolator is preferably a vibration isolator with nonlinear and strong damping characteristics, such as a wire rope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com