Ultraviolet-curable organic/inorganic nano-composited abrasion-resistant transparent coating material and preparation method thereof

A transparent coating, inorganic nanotechnology, applied in the direction of coating, etc., can solve the problems of incomplete curing of the coating, unfavorable production and coating, health hazards, etc., achieve good thermal stability and chemical stability, and low toxicity , non-volatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

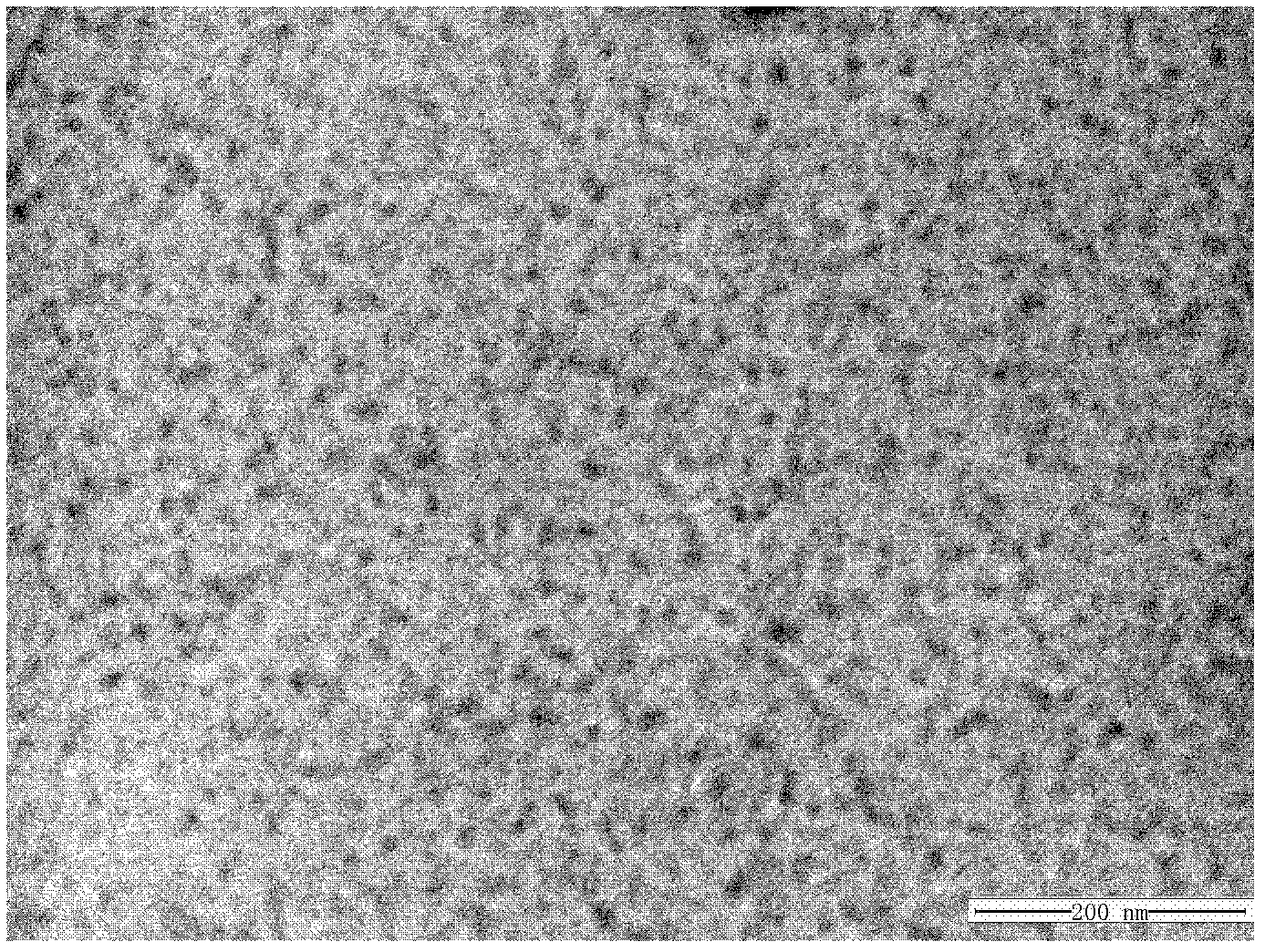

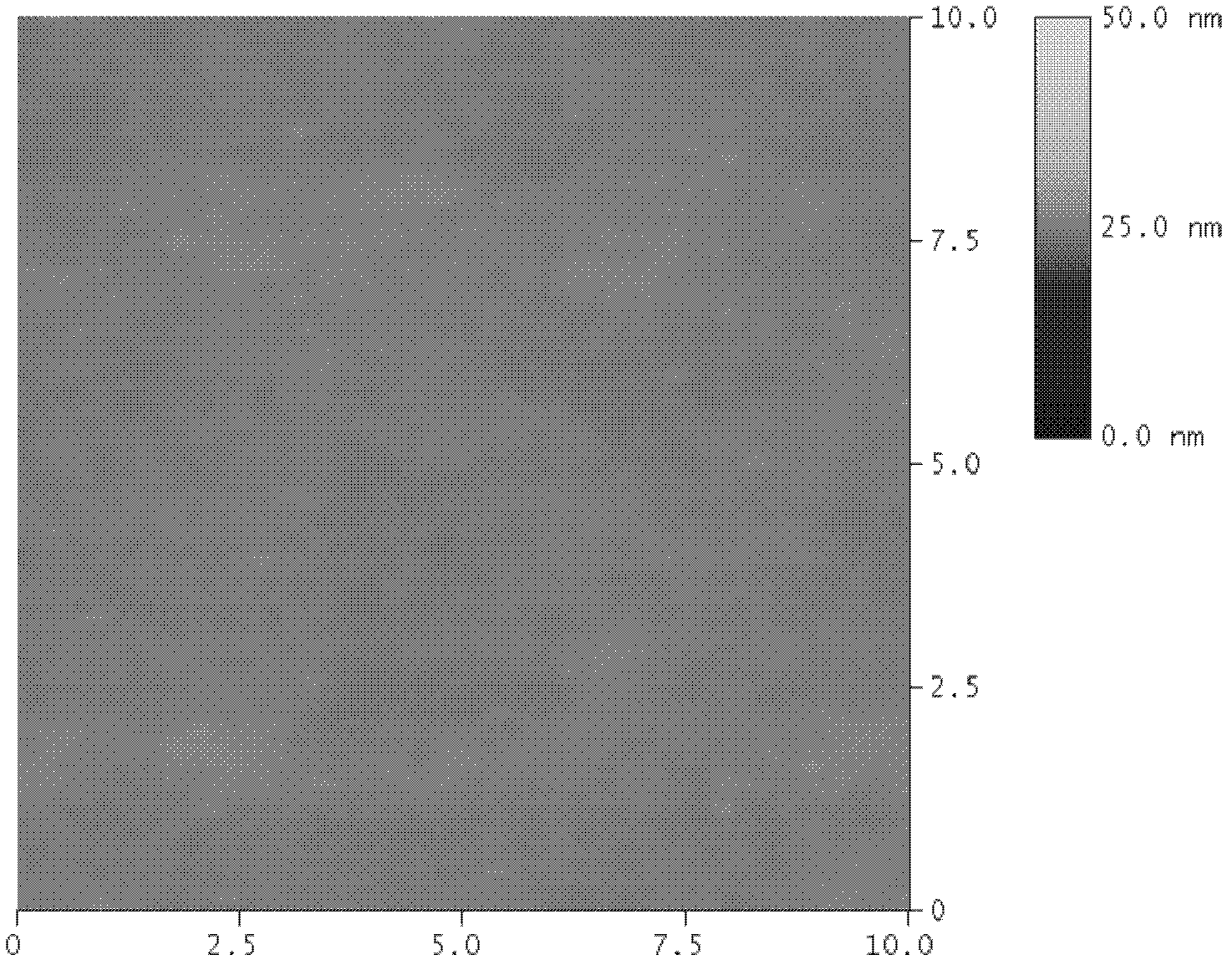

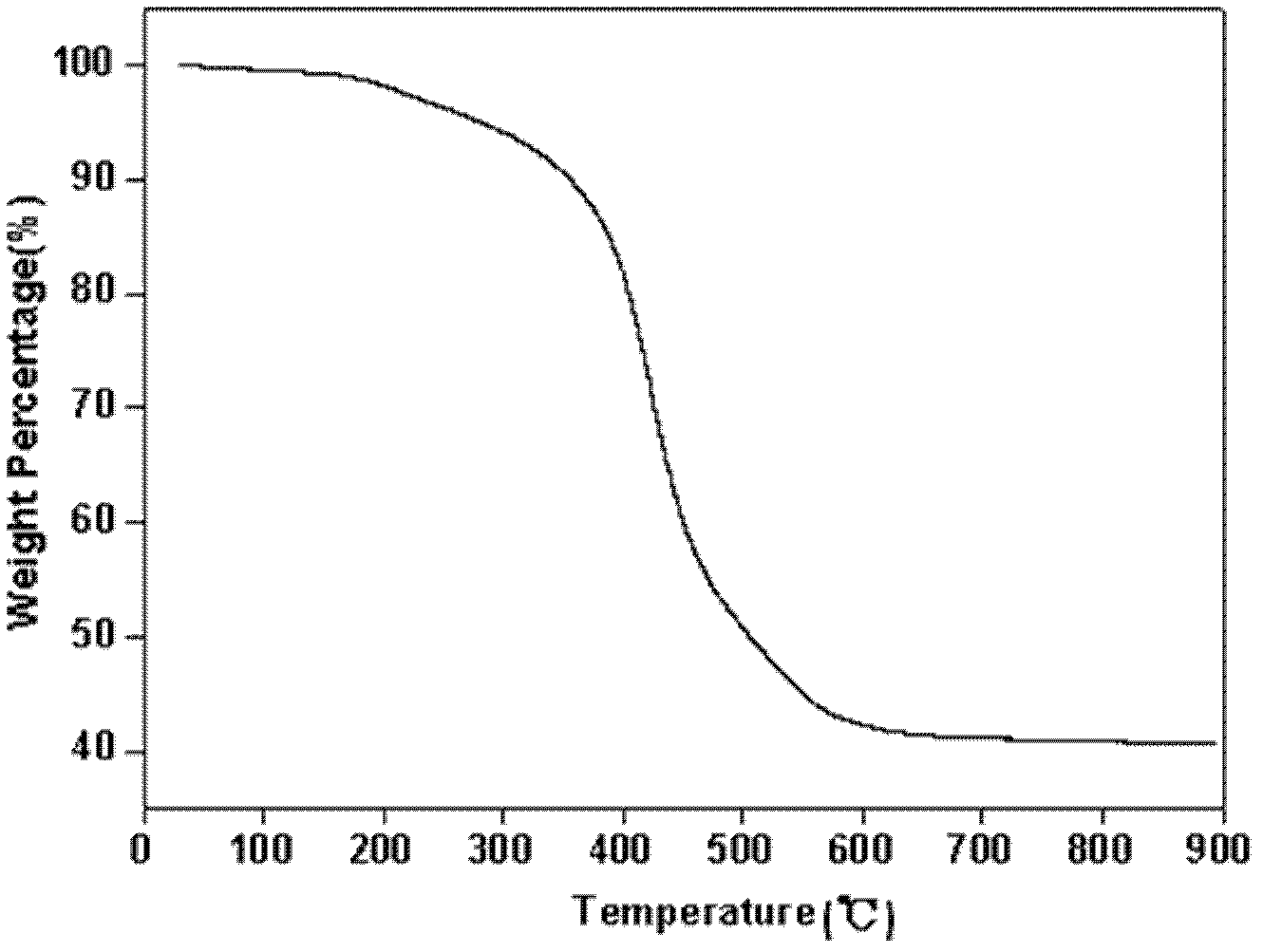

[0041] Example 1:

[0042] Dissolve 35.06g of ethyl orthosilicate and 0.025g of hydrochloric acid (0.12mol / L) in 58.88g of isopropanol, stir evenly; add 14.80g of water to the above solution, and stir for 4 hours; under the condition of continuous stirring Next, add 26.63g Y-glycidyl ether oxypropyl trimethoxysilane (KH560), stir and react for 4 hours; add 53.26g Y-glycidyl ether oxypropyl trimethoxysilane (KH560), stir and react for 4 hours; Heating to 50° C. and stirring for 0.5 hours to obtain a uniform and stable transparent sol. Add 0.80 g of 3-nitrophenyl diphenyl sulfur hexafluorophosphate and 0.38 g of polydimethylsiloxane, stir to make the mixture uniform, and then the coating material of the present invention is obtained. The mass percentage of each component is: ethyl orthosilicate 18.46%; Y-glycidyl ether oxypropyltrimethoxysilane (KH560) 42.08%; isopropanol 31.02%; water 7.80%; phenyldiphenylthio hexafluorophosphate 0.42%; hydrochloric acid 0.013%; polydimethyls...

Example Embodiment

[0044] Example 2:

[0045] The experimental method is the same as that in Example 1, except that 25.62 g of methyl orthosilicate is used instead of 35.06 g of ethyl orthosilicate, and the amount of polydimethylsiloxane added is 0.36 g to obtain a uniform and stable transparent sol. The photoinitiator and the leveling agent are then added, and the mixture is stirred to obtain the coating material of the present invention. The mass percentage of each component is: methyl orthosilicate 14.20%; Y-glycidyl ether oxypropyltrimethoxysilane (KH560) 44.29%; isopropanol 32.64%; water 8.21%; Phenyl diphenyl sulfur hexafluorophosphate 0.44%; hydrochloric acid 0.014%; polydimethylsiloxane 0.20%.

Example Embodiment

[0046] Example 3:

[0047] The experimental method is the same as in Example 1, except that 44.50 g of n-propyl silicate is used instead of 35.06 g of ethyl orthosilicate, and the amount of polydimethylsiloxane added is 0.40 g to obtain a uniform and stable transparent sol. Then add the photoinitiator and the coating auxiliary agent, stir to make the mixture uniform, and then the coating material of the present invention is obtained. The mass percentage of each component is: n-propyl orthosilicate 22.32%; Y-glycidyl ether oxypropyltrimethoxysilane (KH560) 40.08%; isopropanol 29.54%; water 7.42%; 3- Nitrophenyl diphenyl sulfur hexafluorophosphate 0.40%; hydrochloric acid 0.013%; polydimethylsiloxane 0.20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com