Intermittent type waste rubber cracking device

A cracking device and old rubber technology, which is applied in the petroleum industry and the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of ash powder scattering, time-consuming and laborious, and long time for slag removal, so as to achieve safety and environmental protection, improve the working environment, and further The effect of fast material speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

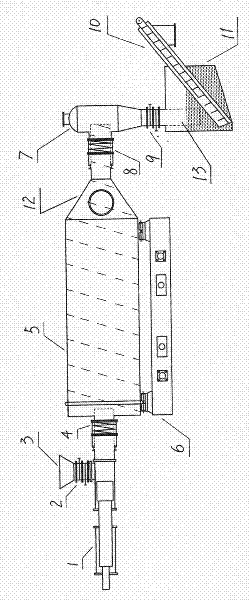

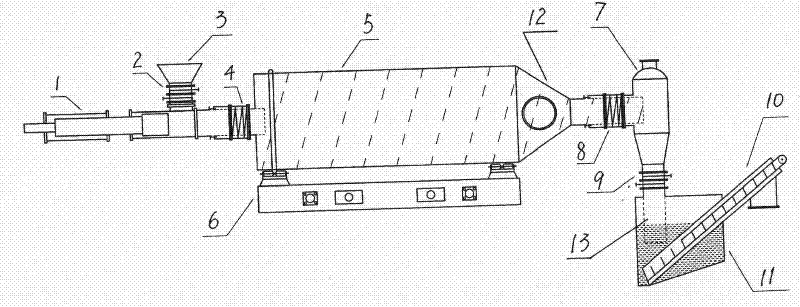

[0009] The invention as figure 1 As shown, it consists of a hydraulic feeder 1, a cracking kettle 5, an air slag separator 7, a combustion furnace 6, a slag discharge pool 11, and high-temperature gate valves 2 and 9. The hydraulic feeder 1 is connected to the On cracking still 5, there is a high-temperature gate valve 2 to be connected between the feed hopper 3 of hydraulic feeder 1 and hydraulic feeder 1; A dynamic and static sealer 8 is connected to the air slag separator 7; the pyrolysis kettle 5 is driven by the gear ring driven by the motor. Since the inner wall of the pyrolysis kettle 5 and the inner wall of the cone 12 at the discharge end are provided with spiral plates, the cracking kettle 5 will crack the gas while rotating. Waste slag is sent to the gas-slag separator 7; the slag outlet of the gas-slag separator 7 is connected to the slag outlet 13 through a high-temperature gate valve 9; the slag outlet of the gas-slag separator is set in the slag outlet pool 11 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com