Tank face integral sealing device for electrodeposition production in sulfuric acid system

A technology of sulfuric acid system and overall sealing, which is applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve the problems of explosion, easy to generate high heat, poor contact, etc., and achieve the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

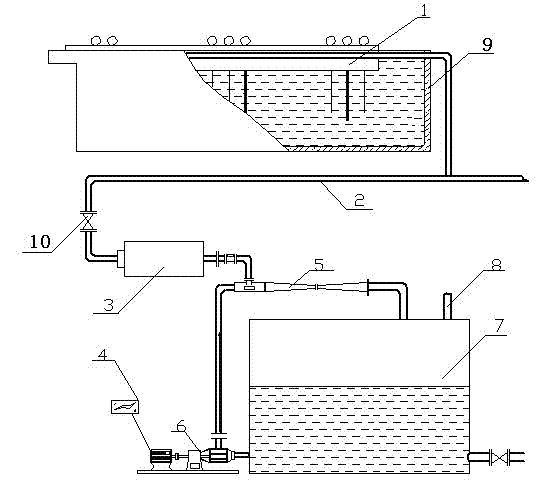

[0034] In the overall sealing device of the tank surface produced electrolytically in the sulfuric acid system of the present embodiment, a tank body sealing cover 1 is provided at the upper opening of the electrolytic cell 9, and two air flow passages are arranged under the tank body sealing cover, and O 2 with H 2 Introduce respectively in a group of independent air guide pipes 2 on both sides of the tank body sealing cover body, O 2 with H 2 Valves 10 and voltage stabilizers 3 are installed on each set of air guide pipes 2 introduced. The outlet end of the voltage stabilizer is connected with the water injector 5 and the circulating water pump 6 respectively through a tee, and the inlet end of the water injector 5 is connected with the circulating water pump. The outlet end of the water pump is connected, and the outlet end is connected to the top of the circulating water tank 7;

[0035] The circulating water pump 6 is connected with the frequency conversion governor 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com