Heating system modifying method for realizing combination of heat and power by straight condensing unit

A pure condensing unit, combined electricity and heat technology, applied in the energy industry, mechanical equipment, steam engine installations and other directions, can solve the problems of large coal consumption, poor environmental protection, low efficiency, etc., to achieve stable and reliable operation, improve economic benefits, environmental protection and energy saving. The effect of social benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Specific implementation plan one, as follows:

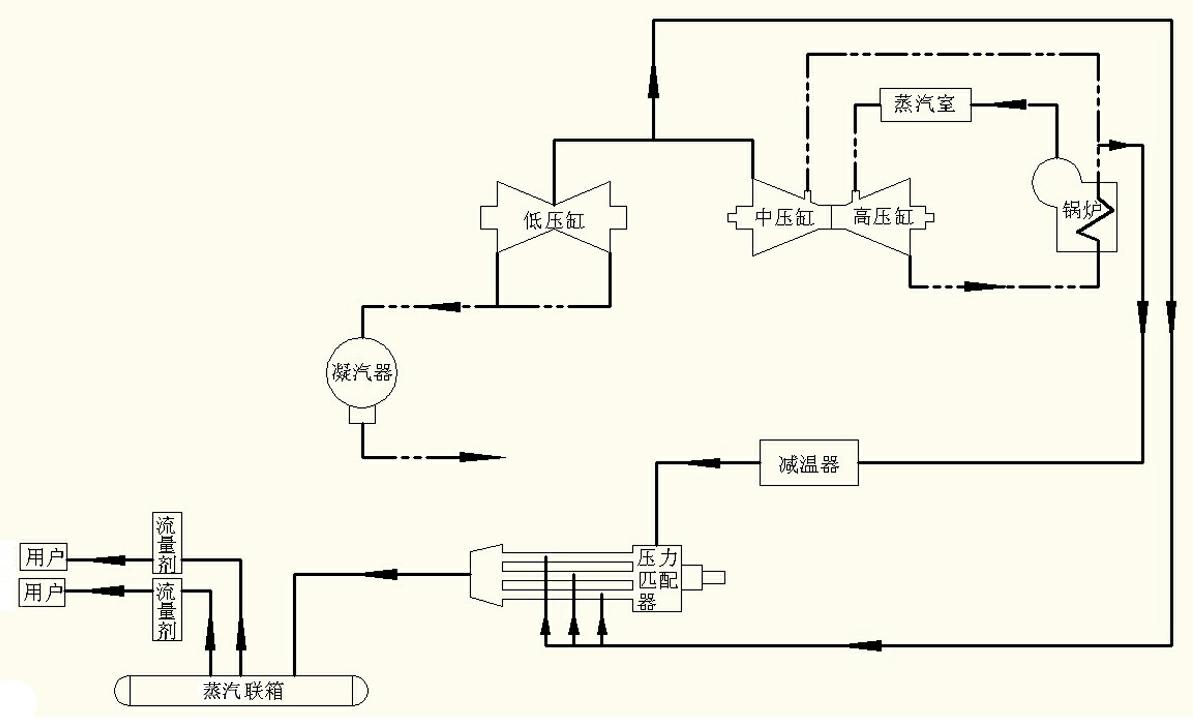

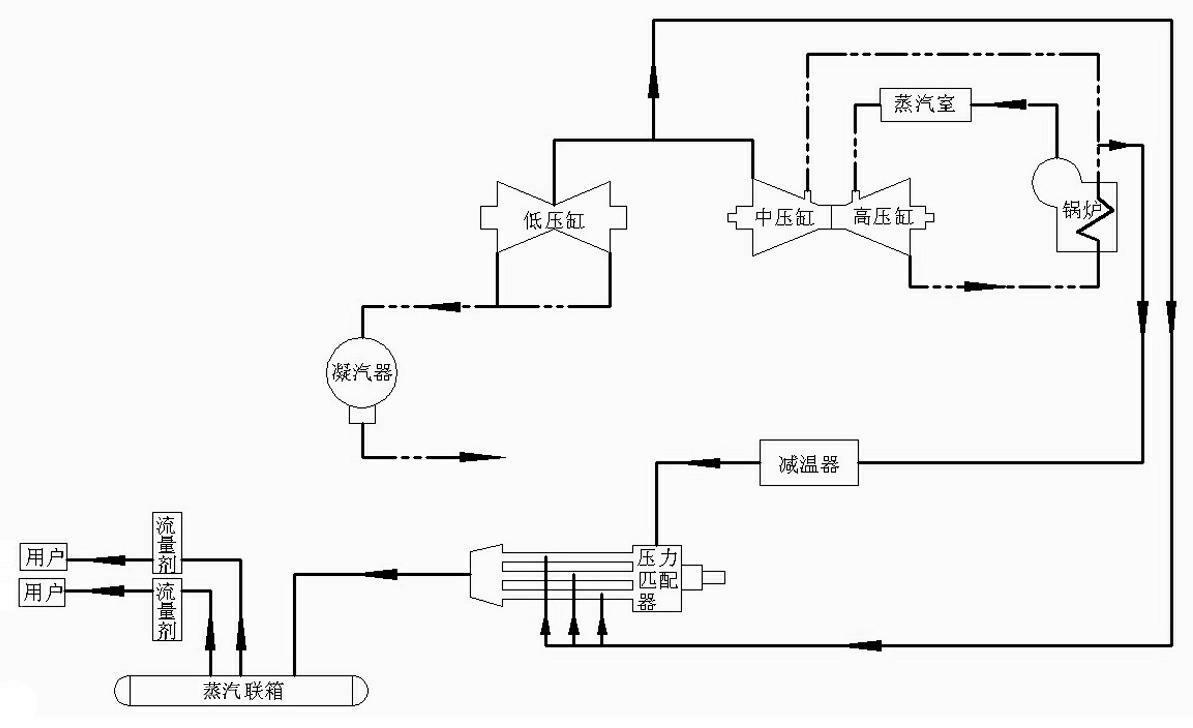

[0024] The power plant now has four 300MW intermediate reheating pure condensing turbogenerator sets. Through transformation, the power plant can supply heat to users in the residential area with a relatively short distance. According to the requirements and the steam parameters of the mid-row extraction steam coming out of the connecting pipe, choose to use the pressure matcher to increase the steam pressure.

[0025] As shown in the figure, the pure condensing turbogenerator set is provided with a high-pressure cylinder, a medium-pressure cylinder and a low-pressure cylinder. The steam exhaust port of the boiler is connected to the steam inlet of the high-pressure cylinder through the steam chamber, and the steam exhaust outlet of the high-pressure cylinder is connected to the boiler. Reheating is carried out, and the reheated high-temperature steam is connected to the medium-pressure cylinder through pipelines, the exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com