Membrane type spring braking air chamber for braking system of truck

A spring brake chamber and brake system technology, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of difficulty in meeting durability requirements, vehicle brake system failure, and limited durability , to achieve the effect of shortening the production cycle, improving performance and service life, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

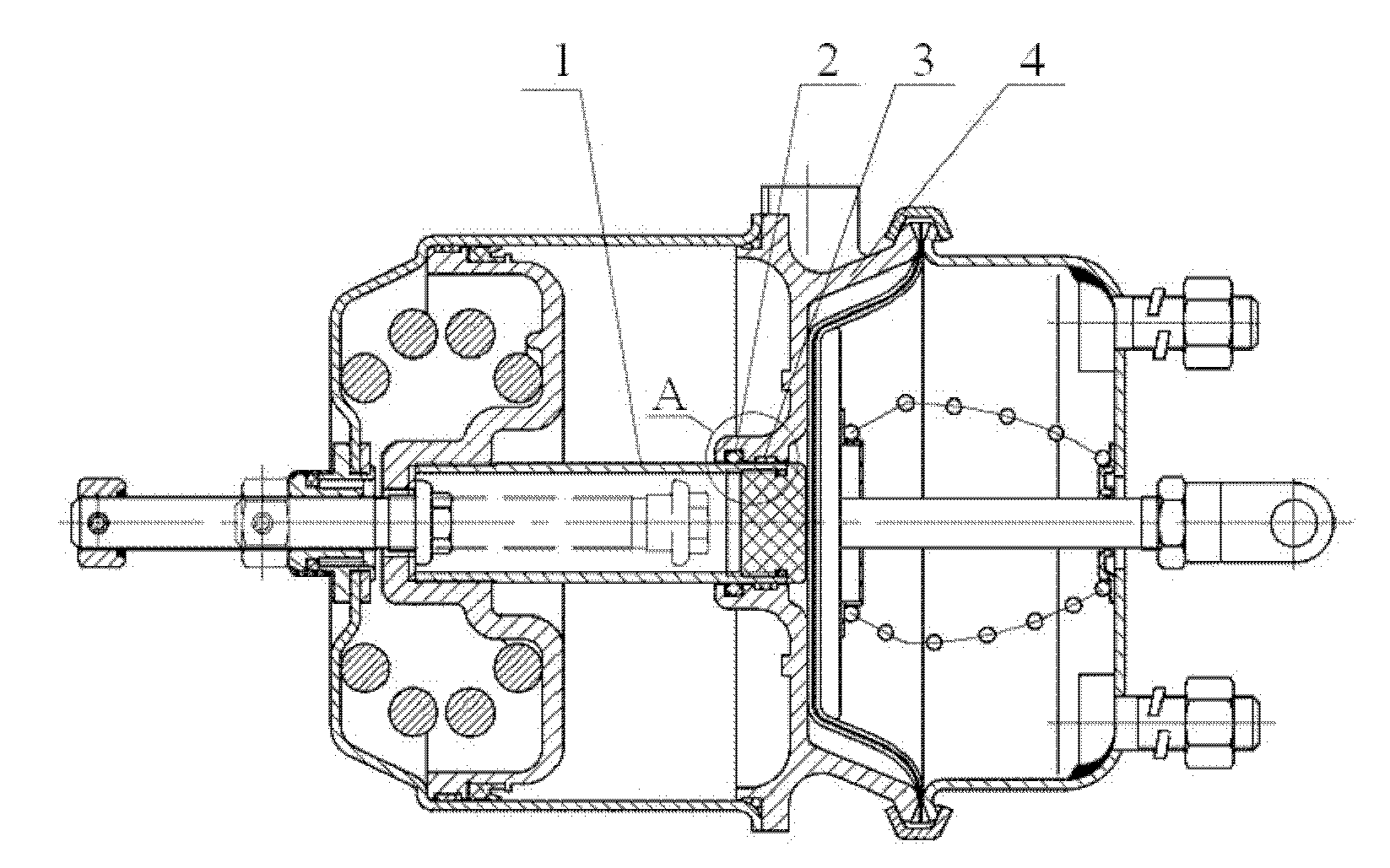

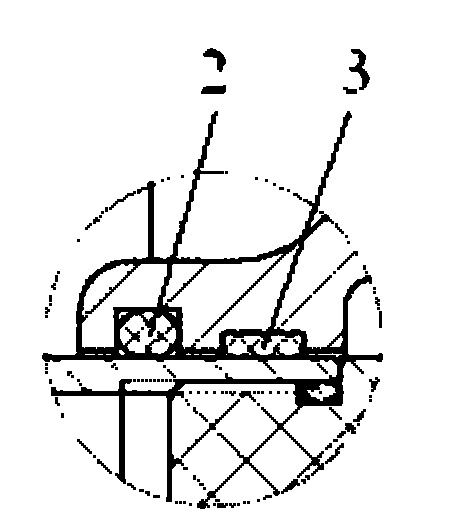

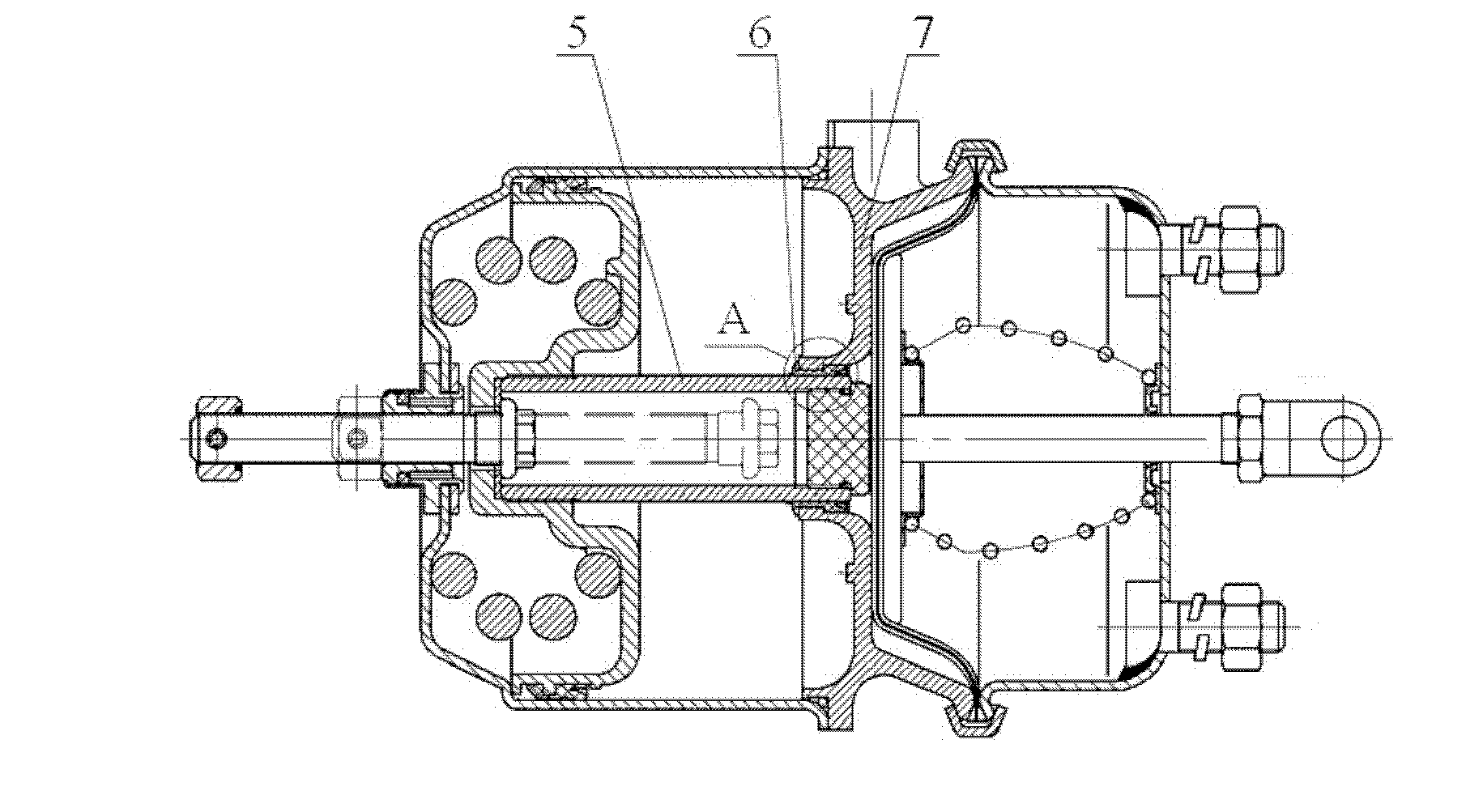

[0020] Such as image 3 , Figure 4 The structure of the present invention expressed is a diaphragm spring brake air chamber of a truck brake system, including a piston assembly 5 and a connecting cover 7 . The diaphragm spring brake air chamber is connected to the mounting bracket of the axle air chamber through mounting bolts, and the push rod fork is connected to the adjustment arm to realize the braking of the output force of the brake.

[0021] Its working principle is:

[0022] The hand valve controls the intake and exhaust of the parking chamber of the diaphragm spring brake chamber, and the piston of the parking chamber m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com