Device for simulating and measuring heat flux of continuous casting covering slag

A continuous casting mold slag and measuring device technology, which is applied in the direction of material thermal development, can solve the problems of difficult control of mold slag volume thickness, inability to measure heat flow, and inability to accurately control mold slag thickness, so as to achieve controllable input heat flow waveform/amplitude , unique structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

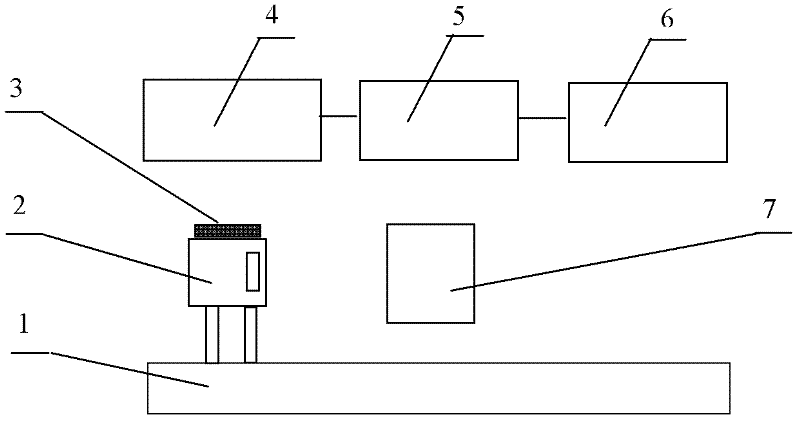

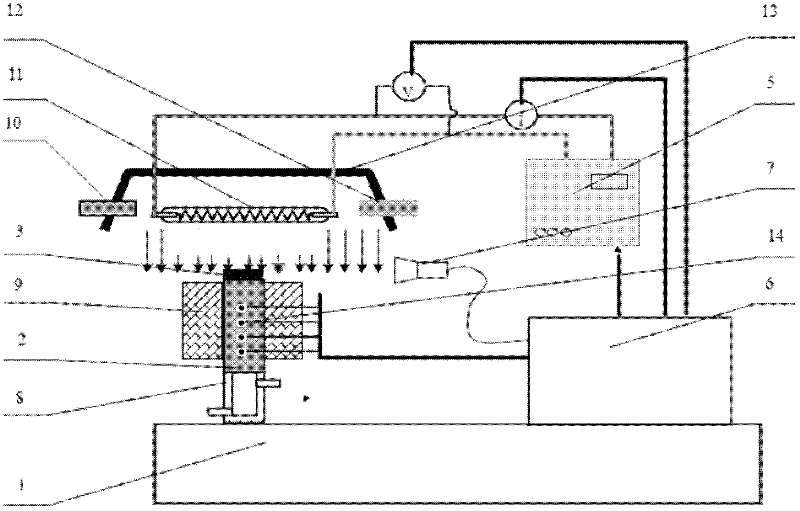

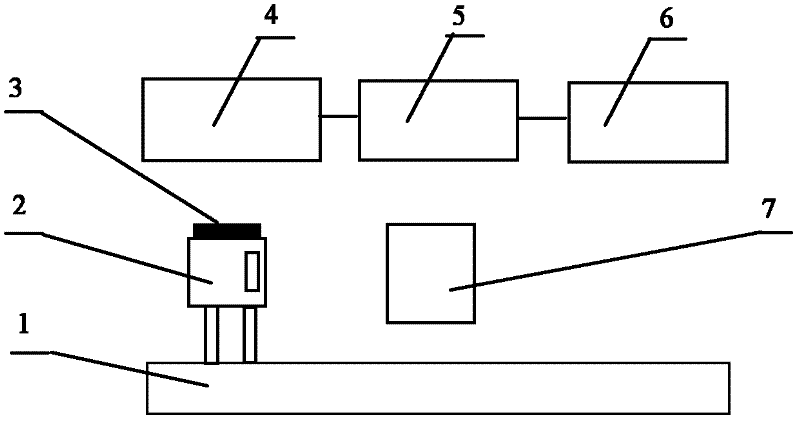

[0025] See attached figure 1 , 2, a continuous casting mold slag heat flow simulation measurement device of the present invention, comprising a heat flow emission system 4, a copper mold crystallizer 2, a power control system 5, a data acquisition / computer control system 6, a digital imaging system 7, the power control system 5 One end is connected to the heat flux emission system 4, and the other end is connected to the data acquisition / computer control system 6. The copper mold crystallizer 2 is placed under the heat flux emission system 4, and the digital imaging system 7 is arranged next to the copper mold crystallizer 2. The heating element 11 of the heat flow emission system 4 is a tungsten / quartz infrared lamp tube; the heat flow waveform output by the heat flow emission system 4 is one of constant wave, square wave, sine wave, pulse wave, trapezoidal wave and disturbance wave , to simulate the change of the outwardly emitted heat flow from the slab due to mold vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com