Method for forecasting leading chromatographic peak shape under multi-order programmed temperature condition

A temperature-programmed, chromatographic peak technology, applied in the field of gas chromatography, can solve the problems of chromatographic peak shape prediction that have not been reported yet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

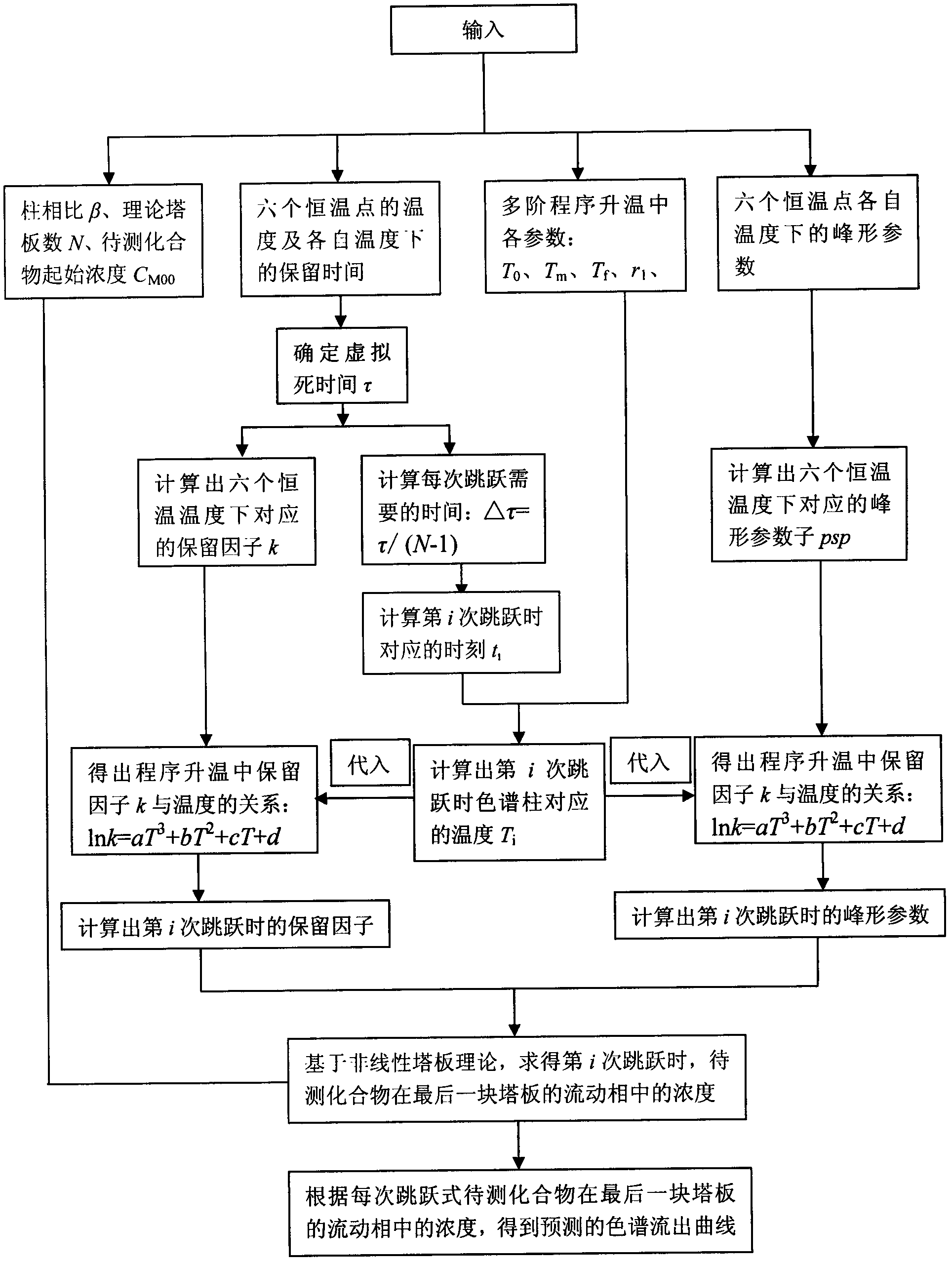

Method used

Image

Examples

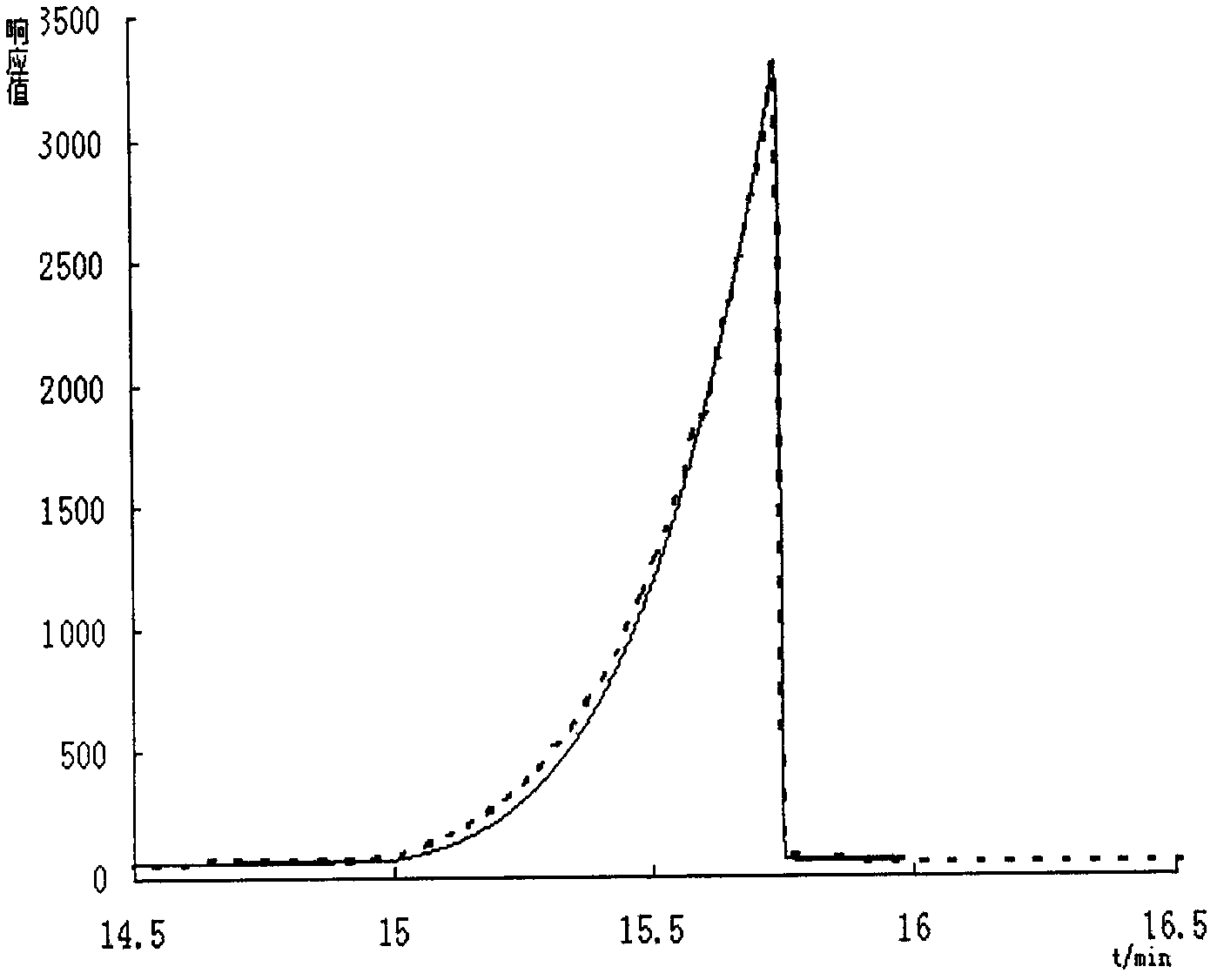

Embodiment 1

[0082] Instruments: HP6890 gas chromatograph, hydrogen flame ionization detector, 6890 gas chromatograph workstation;

[0083] Chromatographic column: non-polar HP-5 (5% phenylmethylpolysiloxane) column;

[0084] Conditions: The temperature of the detector is 250°C, and the temperature of the injection port is 250°C;

[0085] Carrier gas: use high-purity nitrogen gas (purity not less than 99.999%), constant flow operation mode, that is, the carrier gas is at the outlet of the column,

[0086] The mass flow rate is kept constant at 1mL / min;

[0087] Injection method: split injection, the split ratio is 50:1, each injection volume is 0.2 μL, and the concentration is 1 μg / mL;

[0088] (1) Select heptanoic acid as the compound to be tested, and measure its retention time at six constant temperatures of 30°C, 50°C, 100°C, 150°C, 200°C and 250°C on the HP-5 column, which are 25.01min, 14.32min, 7.30min, 3.07min, 2.34min and 2.08min;

[0089] (2) Take the virtual dead time ...

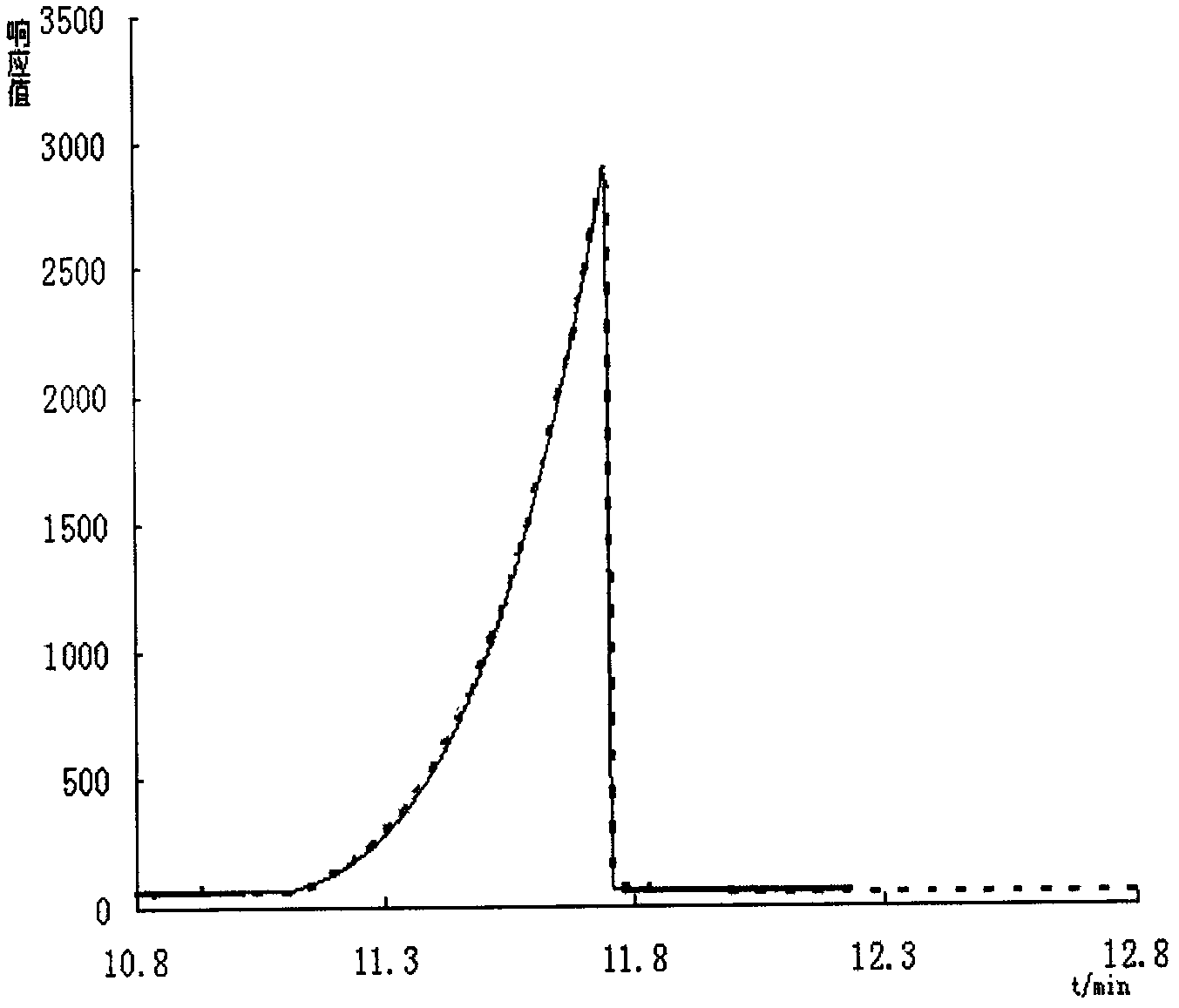

Embodiment 2

[0106] Experimental apparatus, chromatographic column, condition, carrier gas and sample injection mode are the same as embodiment 1;

[0107] (1) Heptanoic acid was selected as the compound to be tested, and its retention times at six constant temperatures of 30°C, 50°C, 100°C, 150°C, 200°C and 250°C were measured on the HP-5 column, which were 25.01min, 14.32min, 7.30min, 3.07min, 2.34min and 2.08min;

[0108] (2) Take the virtual dead time τ=1.85min, and calculate the retention factors of heptanoic acid at six constant temperatures according to formula 1, which are respectively: 2.53, 1.91, 1.08, -0.42, -1.33 and -2.12. At lower temperatures, the distribution of heptanoic acid between the two phases is relatively slow, and is affected by mass transfer resistance diffusion items, etc. Therefore, when using Equation 2 to fit the curves of the relationship between retention factor and temperature at six constant temperatures , the above parameters need to be corrected, and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com