Manufacturing method of but joints of elongated cables for geotechnical engineering instruments

A technology of cable docking and geotechnical engineering, applied in the direction of circuits, connections, electrical components, etc., can solve the problems of insufficient adhesion of hot melt adhesives and unreliable joints, and achieve the effect of easy production, simple production and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. rear.

[0042] A method for manufacturing a geotechnical engineering instrument extension cable butt joint, comprising the following steps:

[0043] (1), PVC cable stripping and cable skin treatment

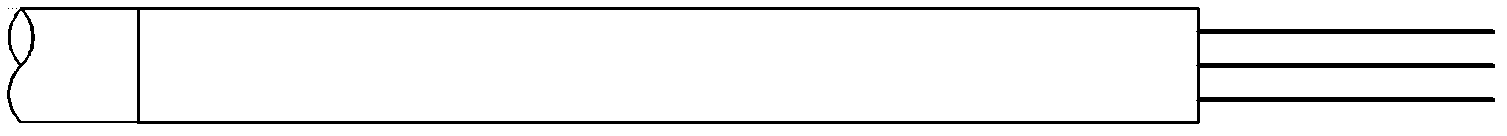

[0044] Such as figure 1 As shown, use wire strippers or other stripping tools to strip the cable core wires, use a file or sandpaper to file the cable skins of the two terminals that need to be connected, and then wipe with a clean rag to remove surface plastic debris and Oil pollution;

[0045] (2), butt joint of PVC cable core wire

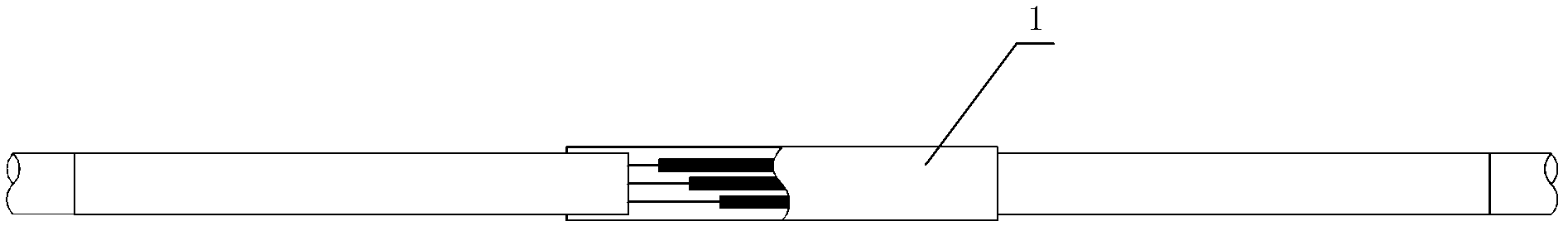

[0046] Such as figure 2 As shown, before the core wires are connected, two heat-shrinkable sleeves with differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com