Frozen waxy wheat dough and production method thereof

A production method and dough technology, applied in baking, baked goods, food science and other directions, can solve problems such as few reports on glutinous wheat flour research, and achieve the effect of improving quality and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

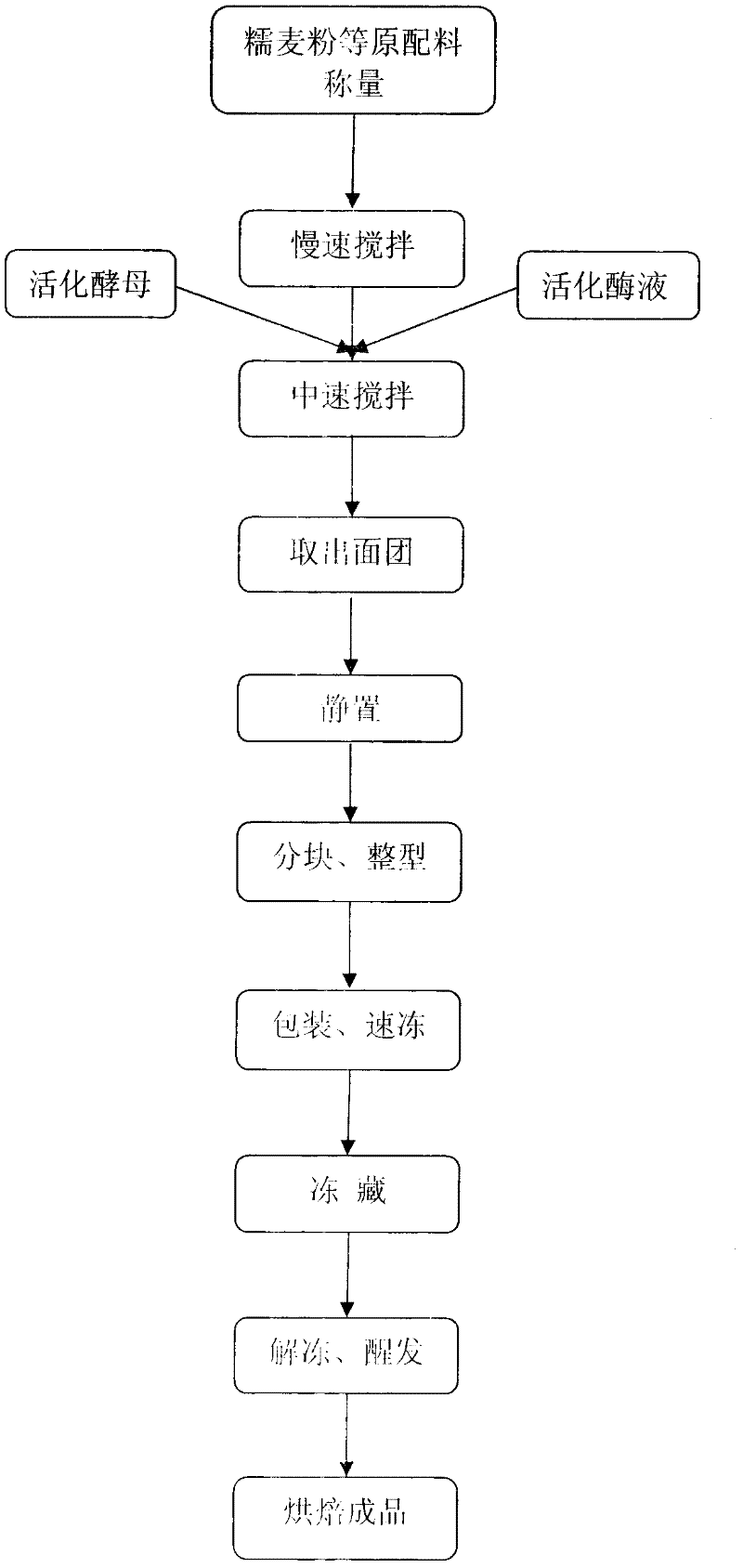

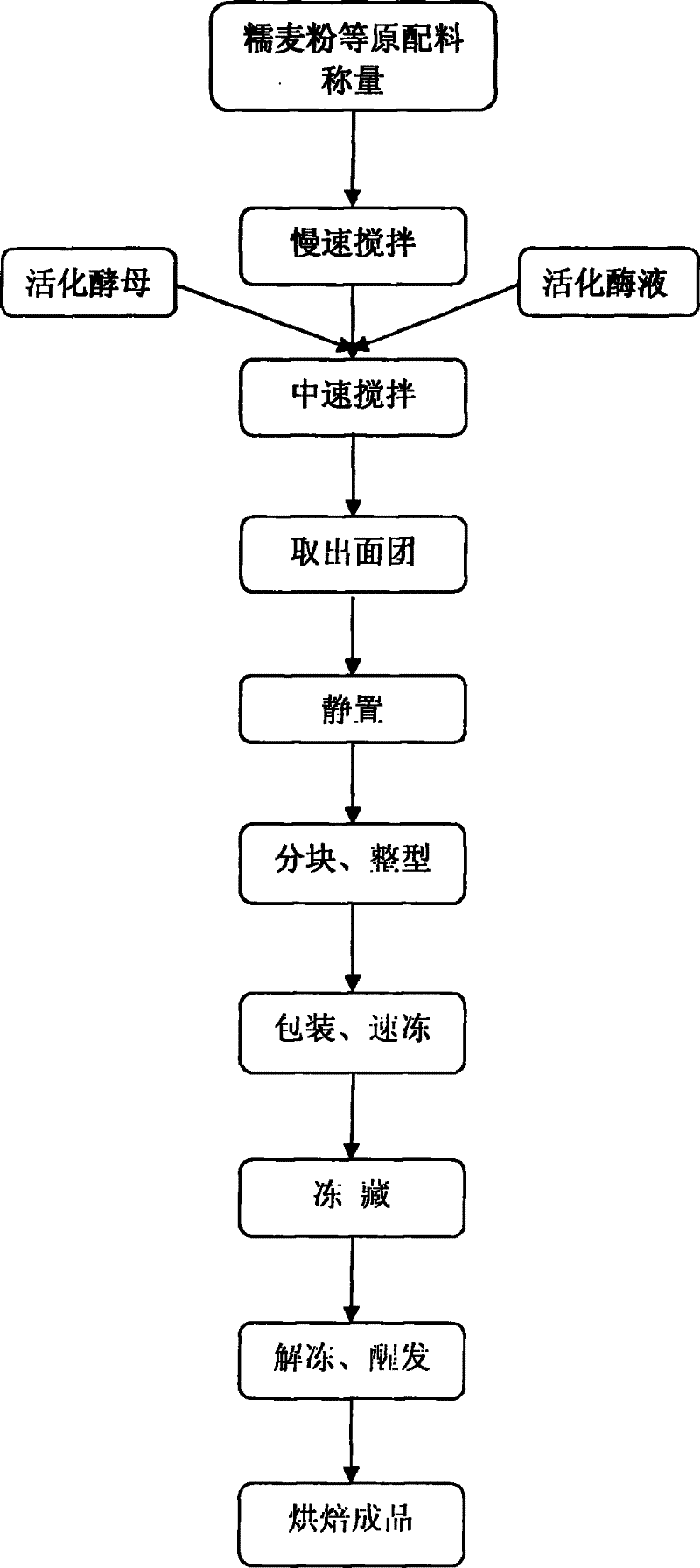

Method used

Image

Examples

Embodiment 1

[0017] In the embodiment of the present invention, glutinous wheat flour: 2.9% by weight; high-gluten flour: 55.0% by weight; shortening: 2.5% by weight; sugar: 2.9% by weight; yeast: 1.0% by weight; water: 34.7089% by weight ; Salt: 0.9% by weight; Trehalose: 0.09% by weight; Glucose oxidase: 0.0011% by weight.

[0018] Dissolve 0.0011% by weight of glucose oxidase in ice water to prepare a solution, the concentration of the solution is 4% by weight, the temperature of ice water is 0-2°C, put it in a constant temperature incubator at 30°C for activation; take 1.0% by weight of active yeast % dissolved in ice water to prepare a solution, the solution concentration is: 2% by weight, and placed in a constant temperature incubator at 28°C for activation. Add glutinous wheat flour, high-gluten flour, granulated sugar, salt, shortening and trehalose into the noodle mixer, mix well, add the remaining ice water, and beat at a slow speed for 3 minutes; continue to stir at a medium spe...

Embodiment 2

[0020] In the embodiment of the present invention, glutinous wheat flour: 11.5% by weight; high-gluten flour: 46.0% by weight; shortening: 1.6% by weight; sugar: 3.7% by weight; yeast: 1.2% by weight; water: 35.2386% by weight ; Salt: 0.7% by weight; Trehalose: 0.06% by weight; Glucose oxidase: 0.0014% by weight.

[0021] Firstly, 0.0014% by weight of glucose oxidase is dissolved in ice water to prepare a solution, the solution concentration is: 3% by weight, the temperature of ice water is: 0-2°C, and placed in a constant temperature incubator at 30°C for activation; take 1.2% by weight of active yeast % dissolved in ice water to prepare a solution, the solution concentration is: 3% by weight, and placed in a constant temperature incubator at 28°C for activation. Add glutinous wheat flour, high-gluten flour, granulated sugar, salt, shortening and trehalose into the noodle mixer, mix well, add the remaining ice water, and beat at a slow speed for 4 minutes; continue to stir at...

Embodiment 3

[0023] In the embodiment of the present invention, glutinous wheat flour: 23.0% by weight; high-gluten flour: 34.1% by weight; shortening: 1.0% by weight; sugar: 4.5% by weight; yeast: 0.9% by weight; water: 35.7883% by weight ; Salt: 0.6% by weight; Trehalose: 0.11% by weight; Glucose oxidase: 0.0017% by weight.

[0024] First take glucose oxidase 0.0017% by weight and dissolve it in ice water to prepare a solution, the solution concentration is: 5% by weight, the temperature of ice water is: 0-2°C, put it in a constant temperature incubator at 30°C for activation and stand-by; take 0.9% by weight of active yeast % dissolved in ice water to prepare a solution, the solution concentration is: 2.5% by weight, and placed in a constant temperature incubator at 28°C for activation. Add glutinous wheat flour, high-gluten flour, granulated sugar, salt, shortening and trehalose into the noodle mixer, mix well, add ice water, stir at a low speed for 2 minutes; continue to stir at a med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com