Natural gas hydrate generating device capable of being quickly disassembled for sampling

A technology for hydrate formation and natural gas, applied in the direction of chemical/physical/physicochemical fixed reactors, etc., to achieve the effects of low cost, simple disassembly, and delayed decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

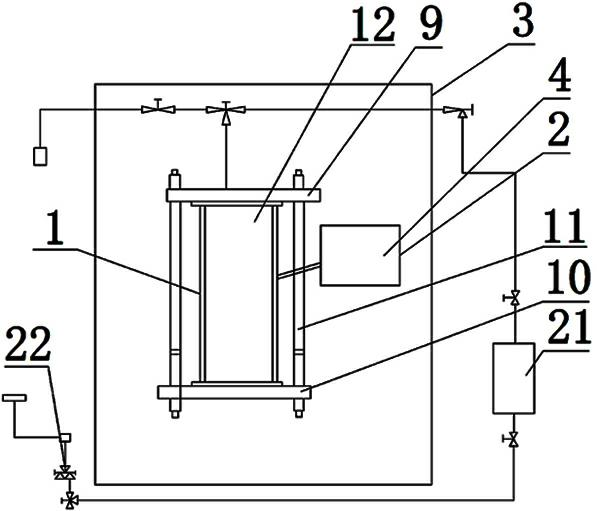

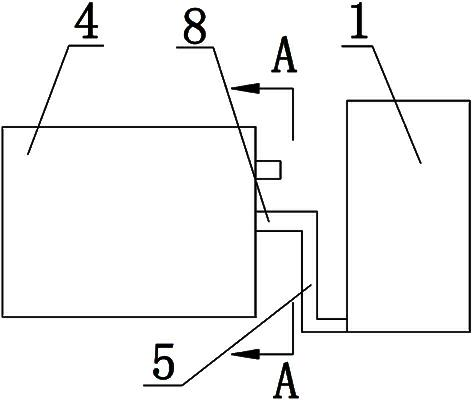

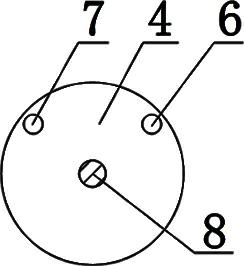

[0029] Such as figure 1 As shown, the gas hydrate generation device that can be quickly disassembled for sampling includes a reactor 1, a stirring device 2 and a DBR bellows 3, such as figure 2 , image 3 As shown, the stirring device 2 includes a reversible motor 4 and a fixed seat 5, the fixed seat 5 is installed on the motor shaft 8 of the reversible motor 4, and the reversible motor 4 is also provided with two limit switches, namely limit switch A6 And the limit switch B7; the reaction kettle 1 is installed on the fixed seat 5, and the stirring device 2 equipped with the reaction kettle 1 is arranged in the DBR bellows 3.

[0030] Such as Figure 4 As shown, the reaction kettle 1 includes an upper end cover 9, a lower end cover 10, a fixed assembly 11 and a plexiglass cylinder 12. An O-ring A13 is arranged between them, and the lower end cover 10 is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com