Modified natural stilbite used as hollow glass adsorbent and preparation method thereof

A technology of stilbite and adsorbent, which is applied in the field of modified natural stilbite and its preparation, can solve problems such as the complex production process of zeolite adsorbent, and achieve the effects of abundant reserves, high grade and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

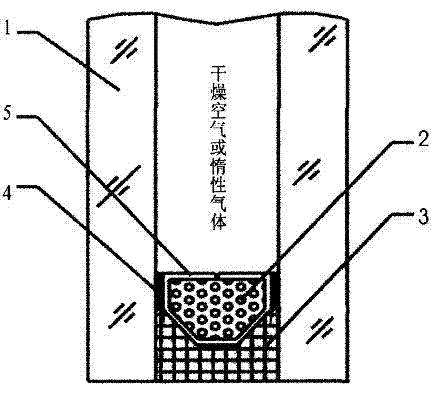

Image

Examples

Embodiment Construction

[0025] Further describe the present invention by embodiment below:

[0026]

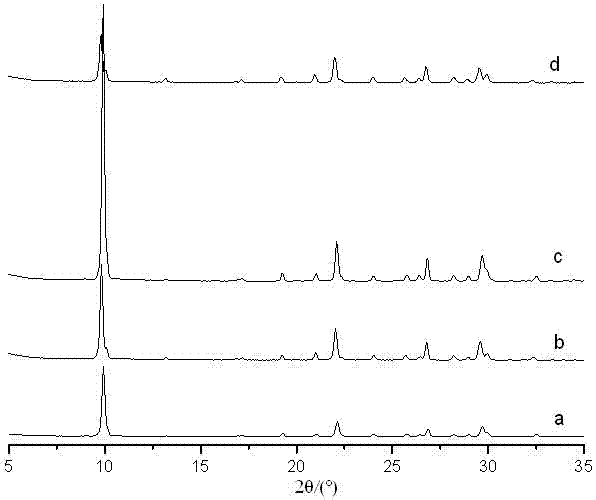

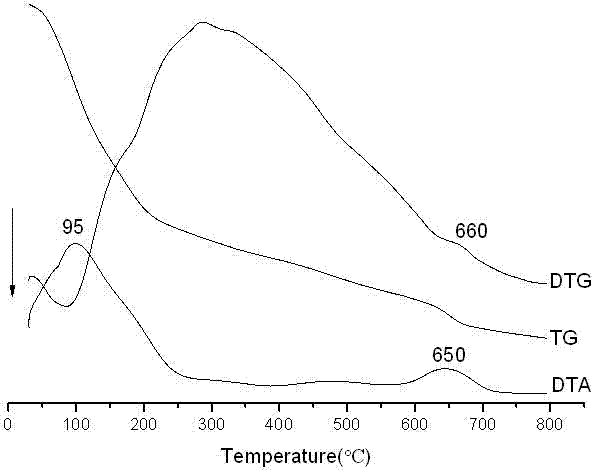

[0027] Taking Example 1 as an example, first prepare 0.1 mol / L NH 4Cl solution, the pulverized STI zeolite raw powder was exchanged at 80°C for 4 times at a solid-to-liquid ratio of 1:10, each time for 2 h, after drying, it was roasted in a tube furnace at 200°C for 3 h to obtain the Invention of the STI zeolite hollow glass adsorbent. After testing, the STI zeolite hollow glass adsorbent has a good moisture absorption effect, and the moisture absorption rate of the zeolite can reach 15.3% at a relative humidity of 75.1%, see image 3 , Figure 4 shown. The STI zeolite hollow glass adsorbents obtained in the remaining examples all have similar properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com