Design method of hot-rolling strip steel rolled cooling line

A technology of hot-rolled strip and design method, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of long design cycle, unclear design process, and inaccurate calculation of equipment parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

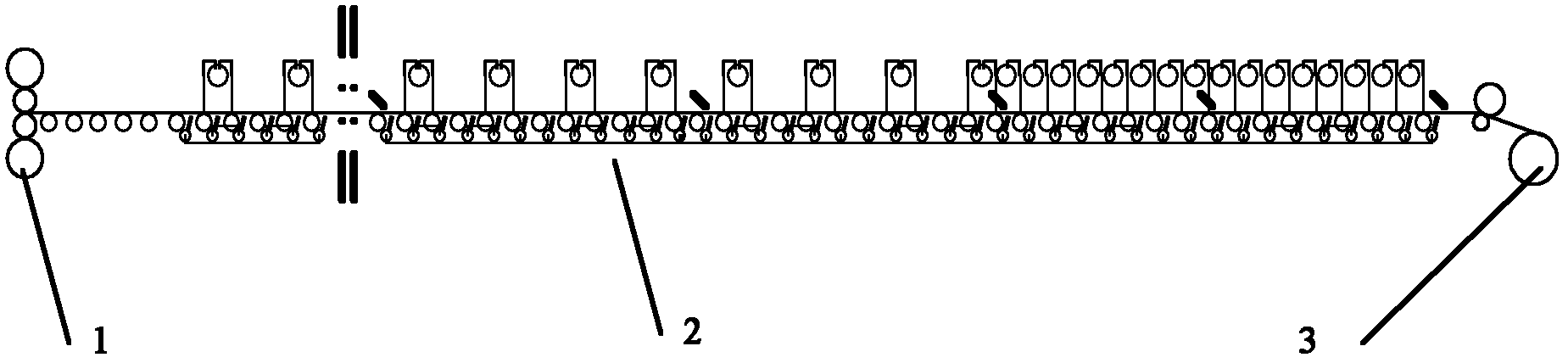

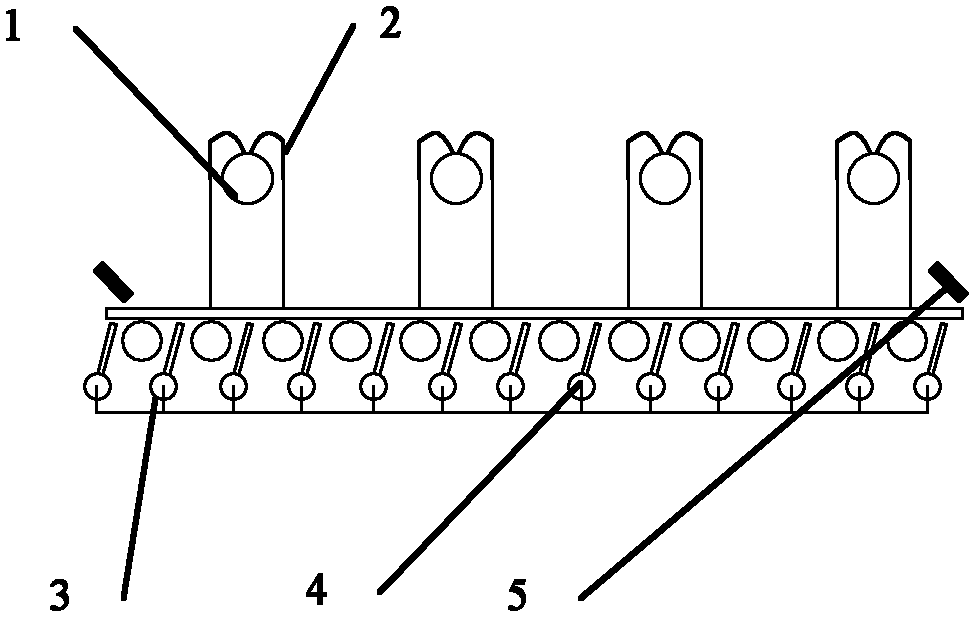

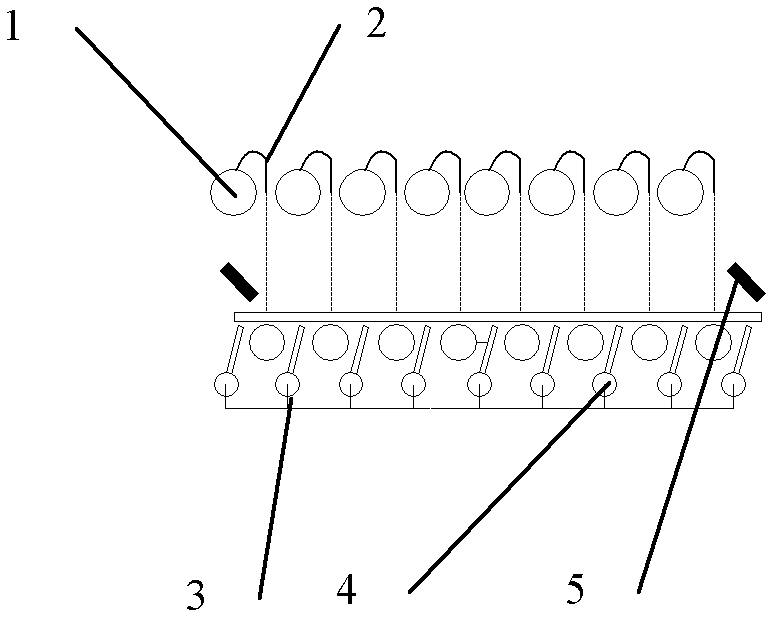

[0066] The present invention will be further described below in conjunction with the accompanying drawings. The design method of the present invention is briefly described by taking a 700mm wide-band hot rolling cooling line as an example.

[0067] The product outline of the hot rolling line is shown in Table 1. Steel types include: plain carbon steel, low-alloy high-strength steel, cold-rolled material, weathering steel, etc.; product thickness ranges from 1.5-10.0mm; width ranges from 290-550mm.

[0068] Cooling line design goals:

[0069] Meet the cooling process requirements of the product outline;

[0070] Put forward cooling line equipment layout and flow requirements;

[0071] Propose cooling line plant design dimensions.

[0072] Table 1 Outline of 700mm hot rolling products with medium and medium width

[0073] Rolled Steel

Representative Steel No.

Finished Thickness Specifications

Finished Width Specifications

Ordinary carbon structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com