Automatic overhauling line and overhauling method of oil pressure vibration absorber

A technology of hydraulic shock absorber and maintenance line, which is applied in the testing of instruments, scientific instruments, mechanical parts, etc., can solve the problems of wasting human resources, troublesome maintenance procedures, and high labor intensity of workers, saving human resources and reducing labor costs. The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

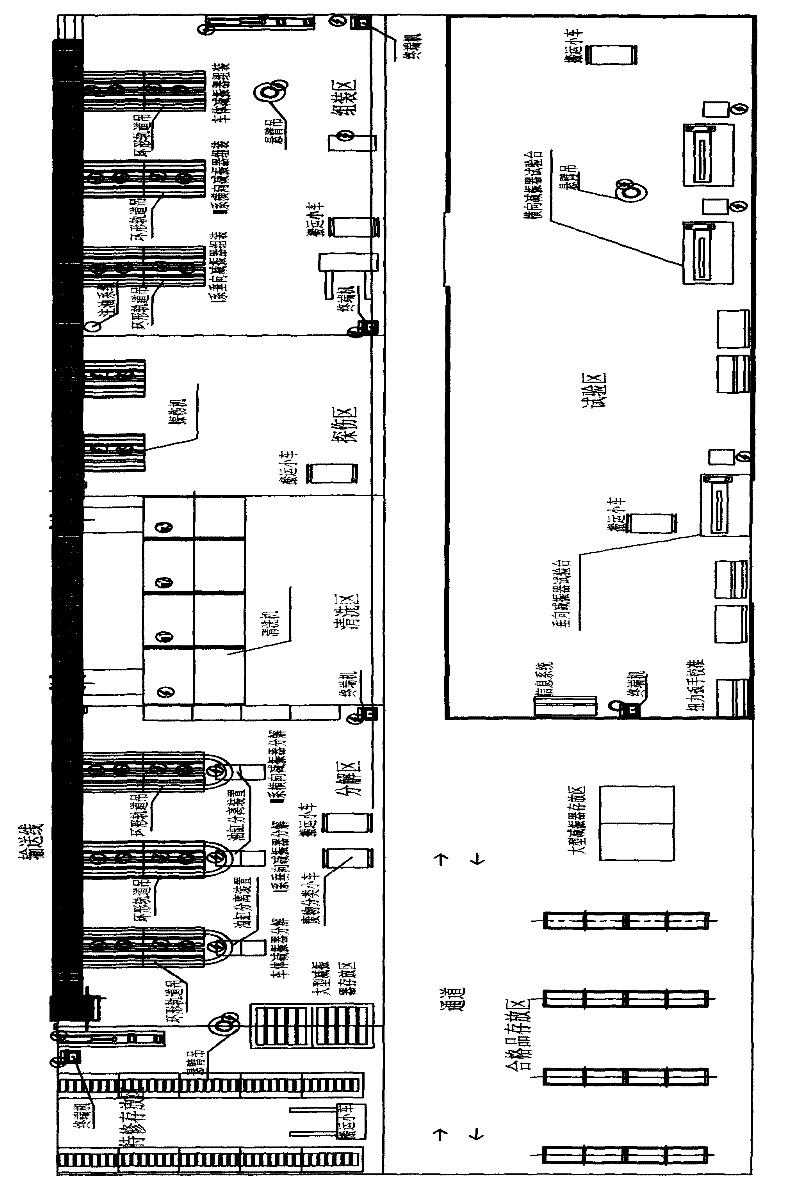

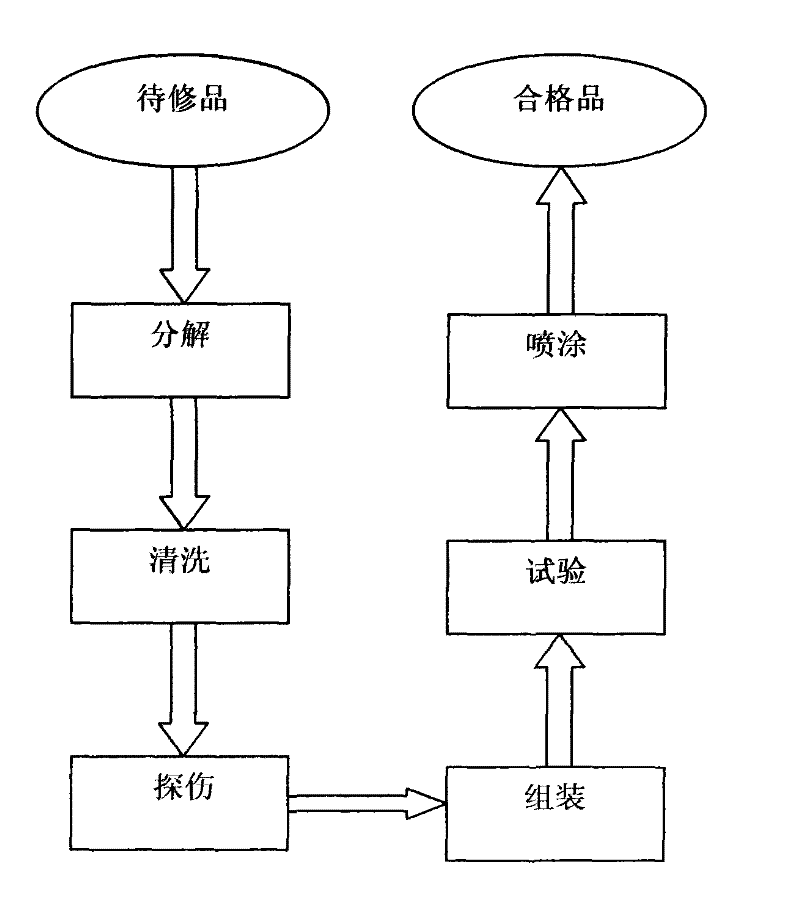

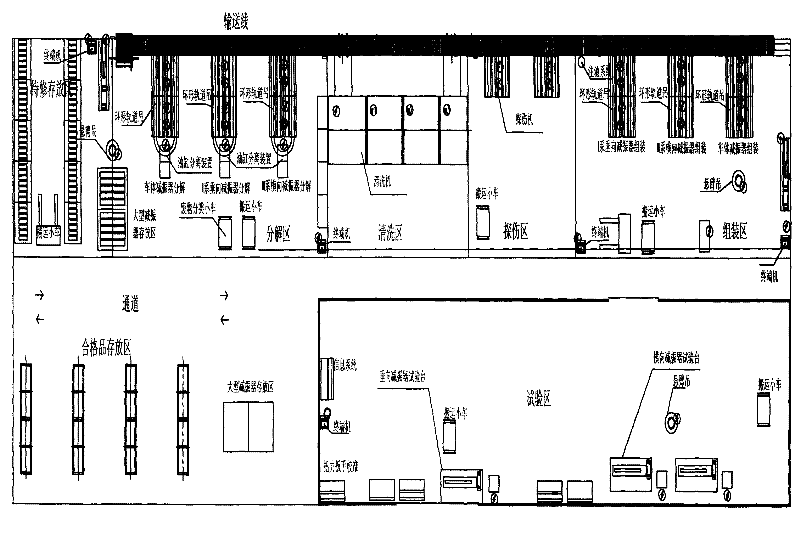

[0039] The present invention will be described in further detail below. see figure 1 , the maintenance line includes the conveying line, the online control management system, the storage area to be repaired, the decomposition area, the cleaning area, the flaw detection area, the assembly area, the test area, and the qualified product storage area connected in sequence;

[0040] The conveyor line includes elevators at both ends of the conveyor line and a control cabinet at one end of the conveyor line connected to the conveyor line through a control cable;

[0041] The storage area to be repaired includes storage racks, pallet bases and handling trolleys;

[0042] The disassembly area is connected to the conveying line through a circular track crane, including car body shock absorber disassembly device, vertical shock absorber disassembly device, lateral shock absorber disassembly device, and manipulator for handling oil pressure shock absorber, which is located next to the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com