Tool clamp capable of adjusting overhang amount of tool in a large range

A technology for adjusting tools and tool clips, which is applied in the direction of manufacturing tools, clamping, metal processing equipment, etc. The effect of reducing the transport load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

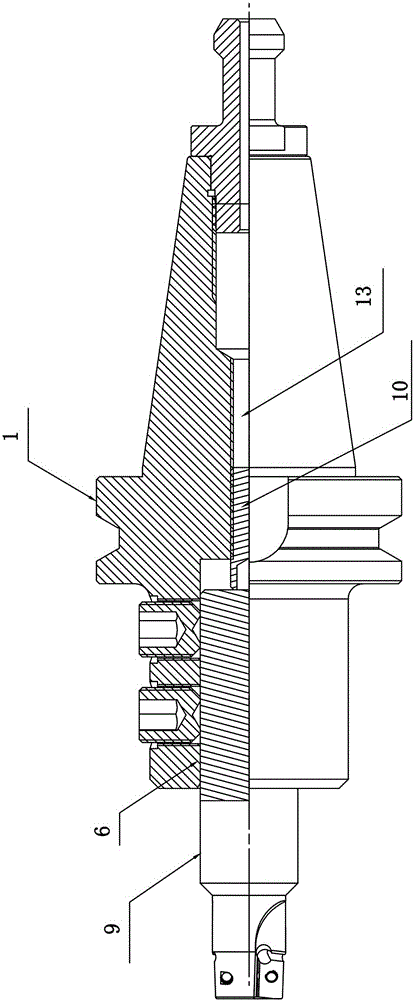

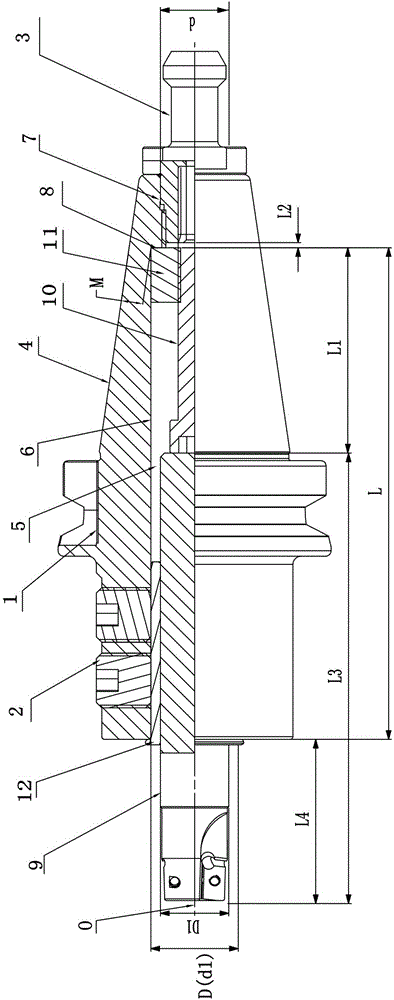

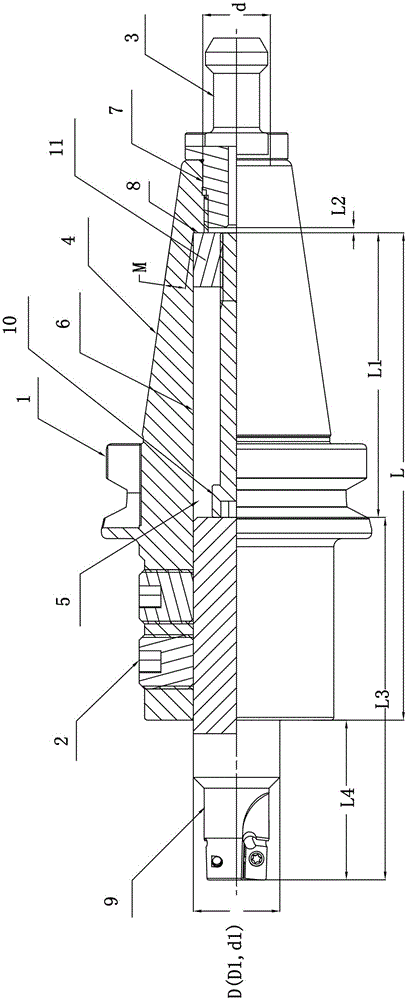

[0020] Figure 2 to Figure 4 It shows a tool clip embodiment of the present invention that can adjust the overhang of the tool in a large range. The tool clip includes a tool clip body 1, a workpiece clamping mechanism 2 and a pull screw 3. The tool clip body 1 is provided with a machine tool. The taper shank part 4 that matches the hole and a cavity 5 that runs through the entire tool holder body 1. The cavity 5 is composed of a tool mounting hole 6 and a standard pull screw hole 7. The diameter D of the tool mounting hole 6 is larger than the standard pull screw hole 7 In this embodiment, D=32mm, d=21mm, the tool installation hole 6 and the standard traction screw hole 7 are connected to form a connecting surface 8, and the tool installation hole 6 is equipped with a detachable adjustment screw 10 and an adjustment nut 11 One end of the adjustment nut 11 is offset against the connection surface 8, and the other end is connected with the adjustment screw 10. The cavity 5 that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com