Integrated technology for high efficiency nitrogen and phosphorus removal based on sludge emission reduction and device thereof

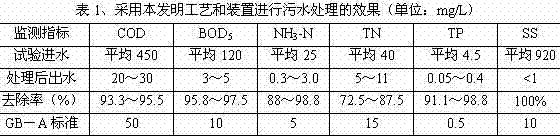

A technology for nitrogen and phosphorus removal and sludge removal, which is applied in the field of environment and municipal engineering to achieve the effect of enhancing phosphorus removal effect, reducing suspended solid concentration, and enhancing the effect of nitrogen removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

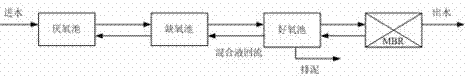

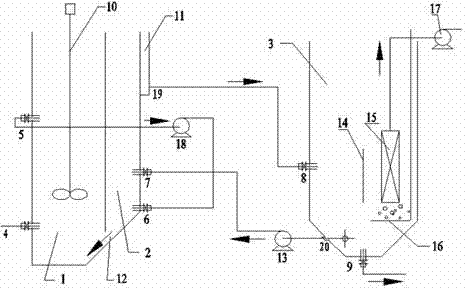

[0023] A high-efficiency denitrification and phosphorus removal integrated process based on sludge emission reduction. The process is as follows: sewage filtered by a grid enters an anaerobic tank from the bottom, and is fully mixed with the sludge in the anaerobic tank under stirring conditions; anaerobic effluent After flowing out from the upper part of the anaerobic tank, it enters the anoxic tank from the bottom and mixes with the sludge in the anoxic tank; the anoxic effluent flows out from the upper part of the anoxic tank and enters the aerobic tank from the middle, where it mixes with the sludge in the aerobic tank. Fully mixed, the mixed liquid circulates in the aerobic tank; a part of the mixed liquid flows out from the lower end of the aerobic tank and returns to the anoxic tank; the other part of the mixed liquid is discharged through the solid-liquid separation of the membrane module. The stirring speed in the anaerobic tank is 50 r / min; the liquid part in the anox...

Embodiment 2

[0026] A high-efficiency denitrification and phosphorus removal integrated process based on sludge emission reduction. The process is as follows: sewage filtered by a grid enters an anaerobic tank from the bottom, and is fully mixed with the sludge in the anaerobic tank under stirring conditions; anaerobic effluent After flowing out from the upper part of the anaerobic tank, it enters the anoxic tank from the bottom and mixes with the sludge in the anoxic tank; the anoxic effluent flows out from the upper part of the anoxic tank and enters the aerobic tank from the middle, where it mixes with the sludge in the aerobic tank. Fully mixed, the mixed liquid circulates in the aerobic tank; a part of the mixed liquid flows out from the lower end of the aerobic tank and returns to the anoxic tank; the other part of the mixed liquid is discharged through the solid-liquid separation of the membrane module. The stirring speed in the anaerobic tank is 40 r / min; the liquid part in the anox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com