Preparation method of chromium methionine chelate

A technology of chromium methionine and chelate, which is applied in the field of preparation of chromium methionine chelate, can solve the problems of no use value, inability to realize continuous production, long operation time, etc., and achieve high reliability of equipment industrialization, crystal form and particle size Good, short operating time results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

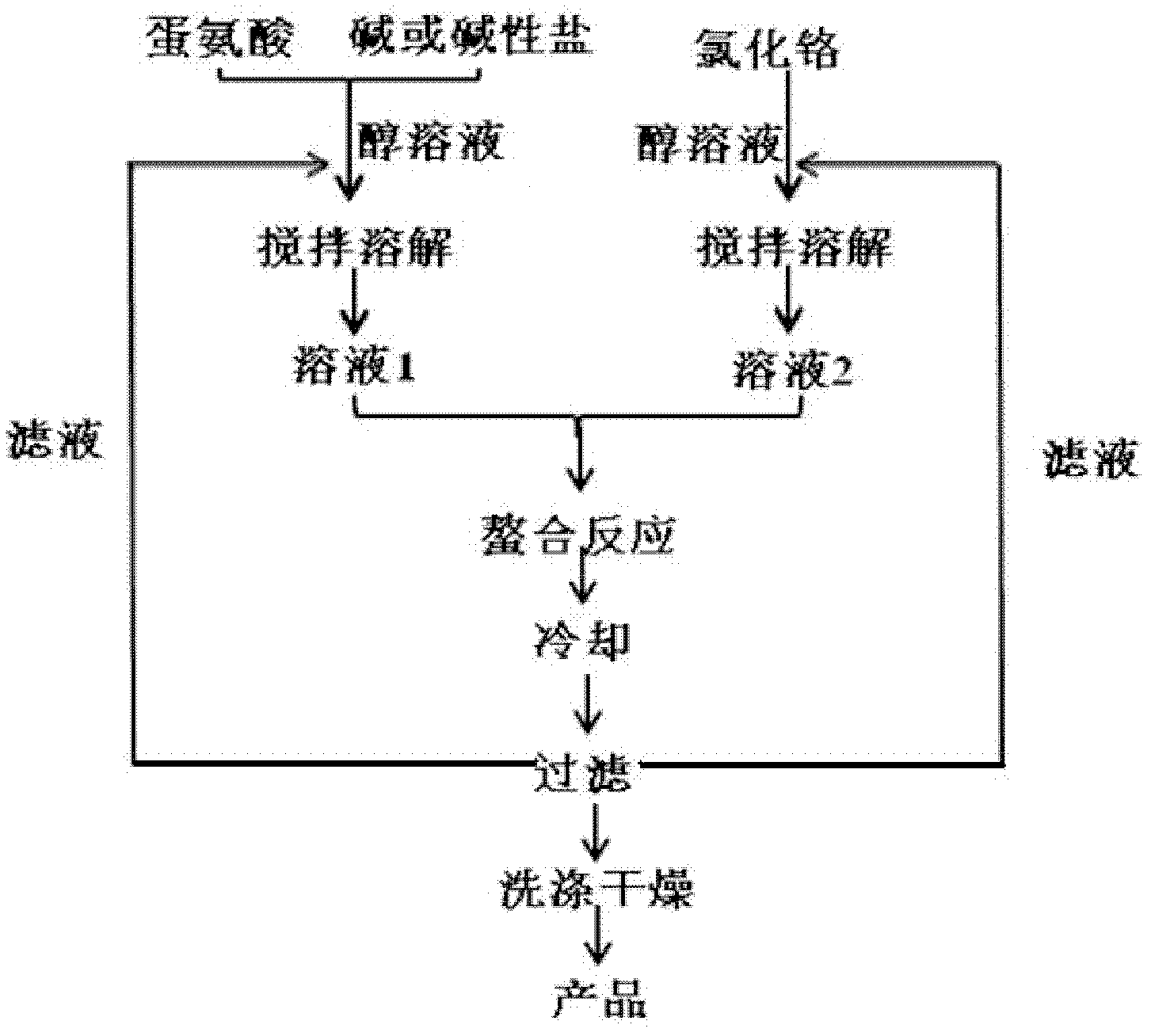

Method used

Image

Examples

Embodiment 1

[0032] 4.5284gD, L-methionine (0.03mol), sodium hydroxide 1.2018g (0.03mol) and absolute ethanol were stirred and dissolved to obtain solution 1. 2.6914 g (0.01 mol) of chromium chloride and absolute ethanol were stirred and dissolved to obtain solution 2, to which solution 1 was added. React at 90°C for 0.5 hours under normal pressure. After the completion of the reaction, cooling, filtering, washing, and drying were performed to obtain a purple-red crystalline powder with a yield of 86.6% of chromium methionine chelate.

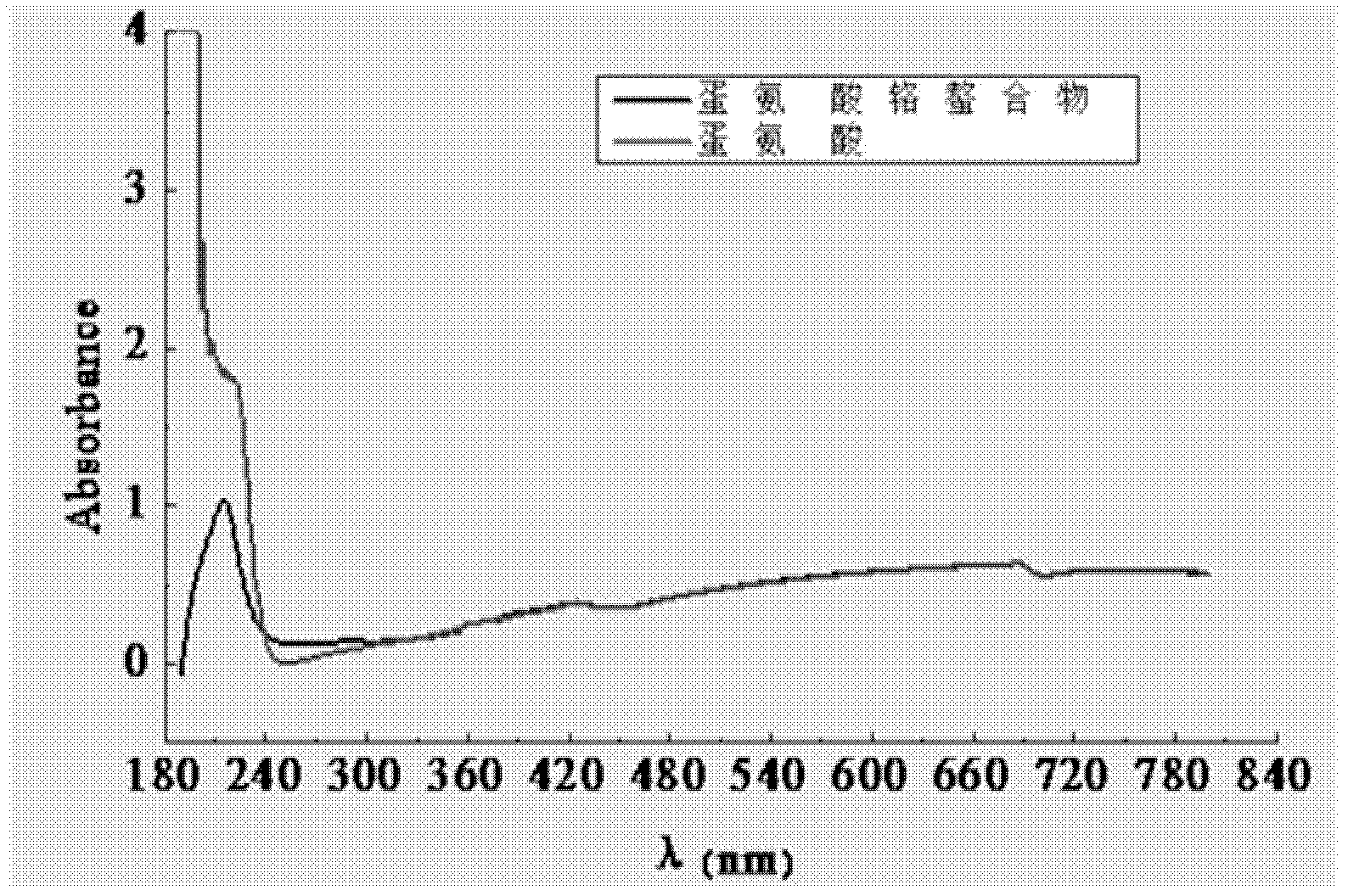

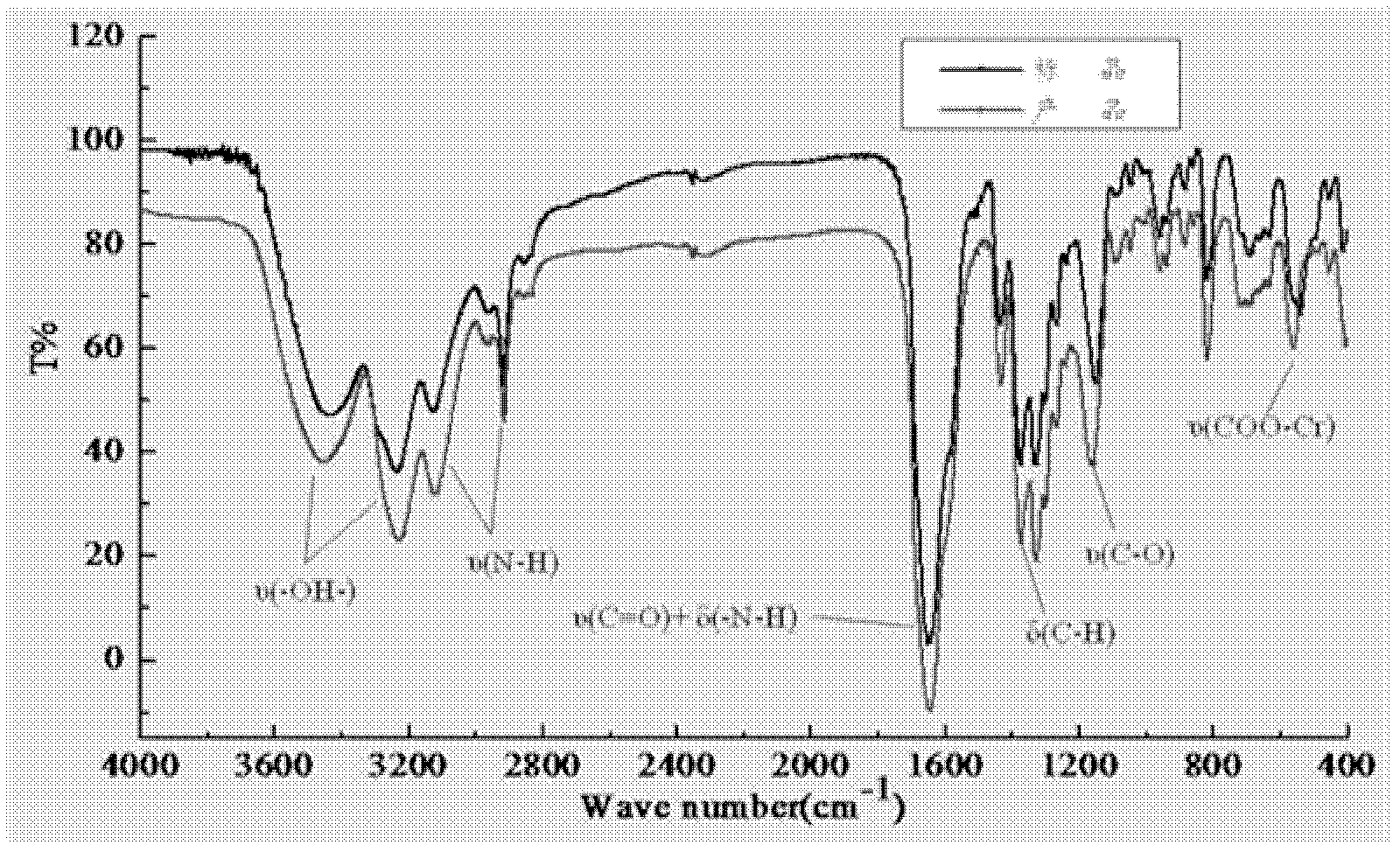

[0033] The synthesized product was qualitatively characterized by ultraviolet and infrared spectroscopy, see figure 2 and image 3 . The content of trivalent chromium in the product is determined by ICP method, and the content of methionine is determined by pre-column derivatization high performance liquid chromatography. The trivalent chromium content is 10.09% and the methionine content is 89.27%

Embodiment 2

[0035] 3.0143g D,L-methionine (0.02mol), potassium hydroxide 1.122g (0.02mol) and 10% ethanol solution were stirred and dissolved to obtain solution 1. 2.6921 g (0.01 mol) of chromium chloride and a 10% ethanol solution were stirred and dissolved to obtain solution 2, to which solution 1 was added. React at 30°C for 3 hours under normal pressure. After the completion of the reaction, cooling, filtering, washing, and drying were performed to obtain a purple crystalline powder. The yield of chromium methionine chelate was 84.8%. The content of trivalent chromium is 14.82%, and the content of methionine is 85.04%

Embodiment 3

[0037] The experimental procedure is the same as above, and the reaction conditions are as follows: D, L-methionine 1.5072g (0.01mol), sodium carbonate 0.5318g (0.005mol) chromium chloride 2.6918g (0.01mol), 10% ethanol solution, normal pressure, 90℃, React for 3 hours. The yield of methionine chromium chelate is 92.6%. The trivalent chromium content is 25.91%, and the methionine content is 74.02%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com