Treatment method of turbid underflow in novel liquid storing tank used in zinc smelting

A processing method and technology for zinc smelting, which can be applied to the improvement of process efficiency, photography process, instruments, etc., and can solve the problems of fluctuation of electrolysis process, decline of electrolytic zinc quality and output, and increase of impurities in electrolyte.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

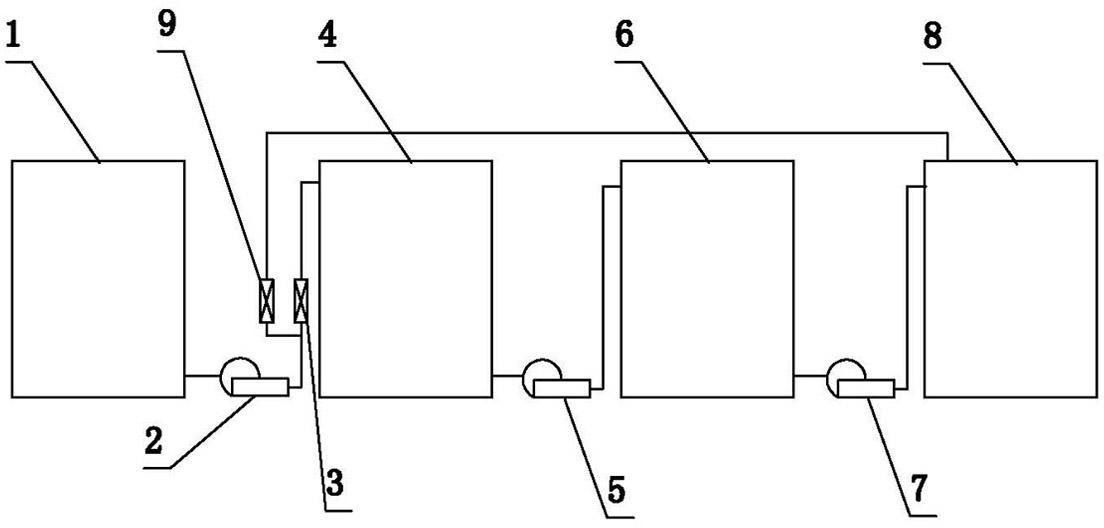

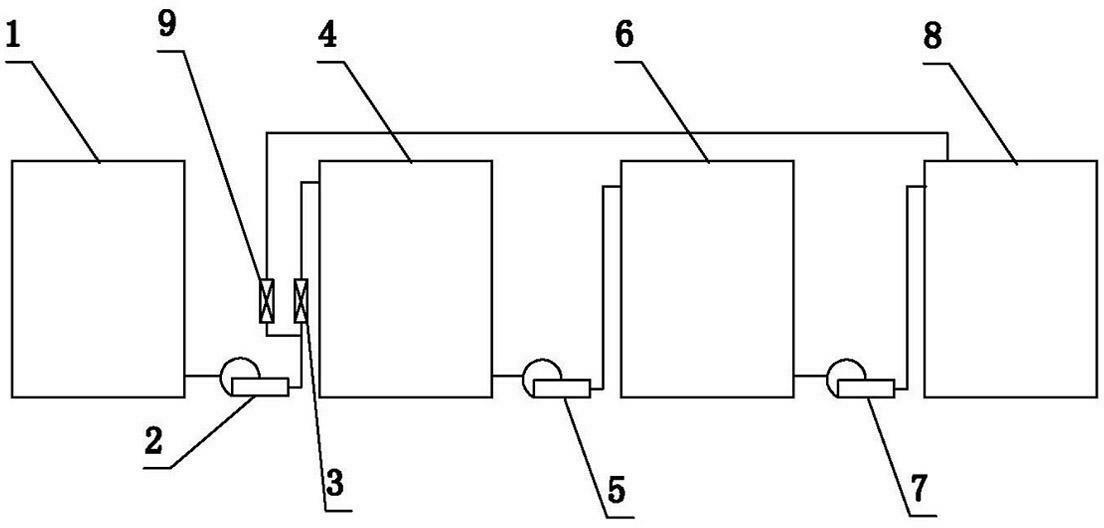

[0014] A method for treating the turbid bottom flow of a zinc smelting new liquid storage tank, the steps of the method are as follows:

[0015] Step 1, close the waste liquid valve 9 and the new liquid valve 3, and add a sufficient amount of new liquid into the new liquid storage tank 1, and then let it stand still;

[0016] Step 2, after some impurities inside the new liquid slowly settle at the bottom of the new liquid storage tank, open the waste liquid valve 9, start the new liquid pump 2 to extract the turbid underflow of the new liquid from the new liquid storage tank 1 and pass through the opened waste liquid valve 9 injected into the waste liquid storage tank 8;

[0017] Step 3, after continuously extracting the turbid underflow of the new liquid from the new liquid storage tank 1 for 5-10 minutes, close the waste liquid valve 9, open the new liquid valve 3, use the new liquid pump 2 to extract the new liquid from the new liquid storage tank 1 and pass it through the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap