Biopolymer fiber composite covering yarn structure

A technology of biomass fiber and core-spun yarn, applied in the field of textile yarn, can solve the problems of unbearable for consumers, high price of white silk, and restrictions on the development and application of yarn varieties, and achieves ideal softness and excellent green environmental protection effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

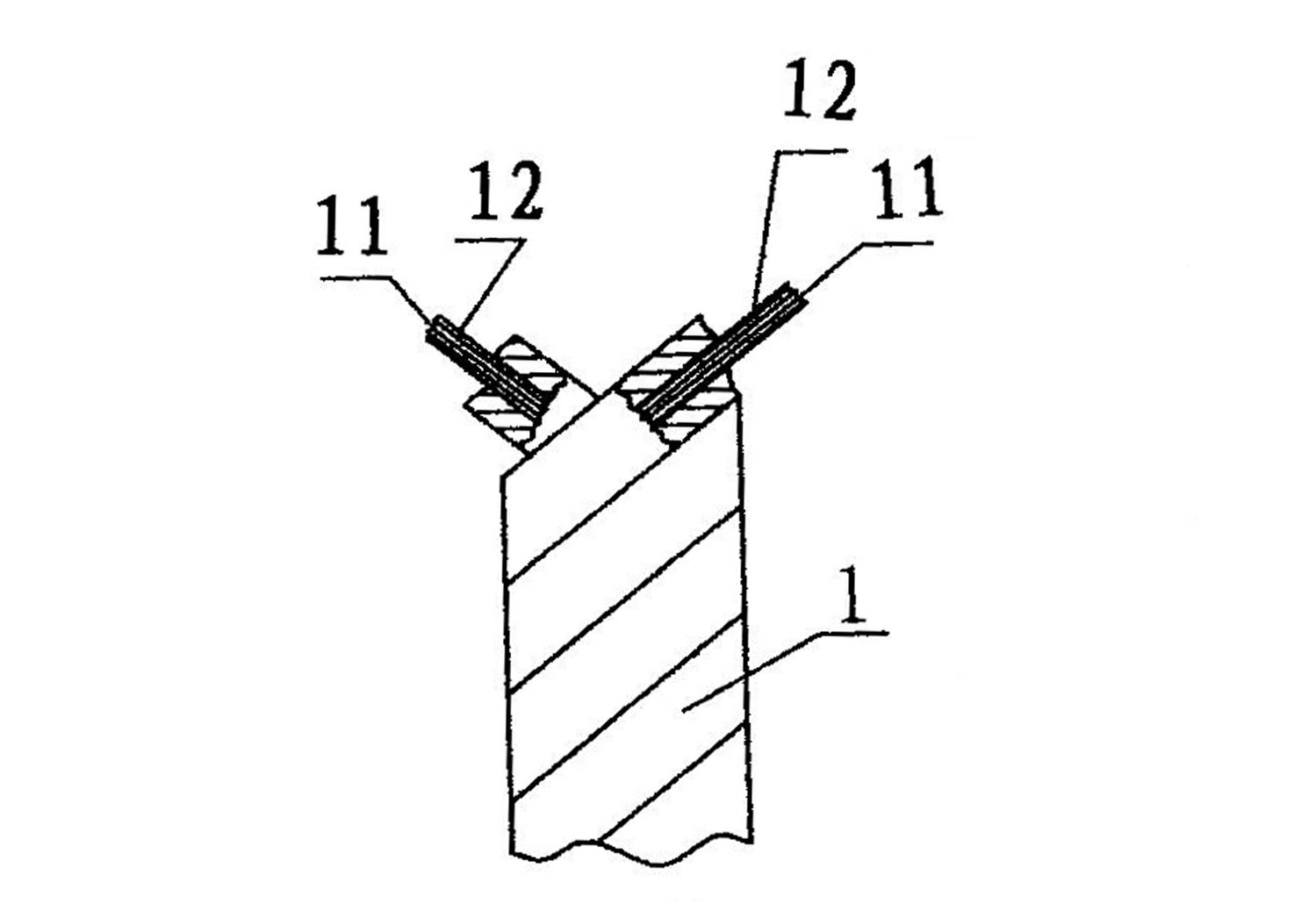

[0018] please see figure 1 , two polylactic acid filaments of the same specification and two biomass spun yarns 12 are given, and biomass spun yarns 12 are combined outside each polylactic acid filament 11, that is, polylactic acid filaments 11 and The biomass spun yarn 12 is wound in a helical shape and according to the required pitch to form a helical winding structure, and then two groups of core-spun yarns each consisting of a polylactic acid filament 11 and the biomass spun yarn 12 are helically wound to each other. twisted to form a yarn body 1. Wherein: the biomass spun yarn 12 is combined outside the polylactic acid filament 11. In this embodiment, the polylactic acid filament 11 is a polylactic acid multifilament, and the polylactic acid multifilament is composed of a plurality of polylactic acid monofilament bundles; the biomass spun yarn 12 is a bamboo charcoal fiber.

Embodiment 2

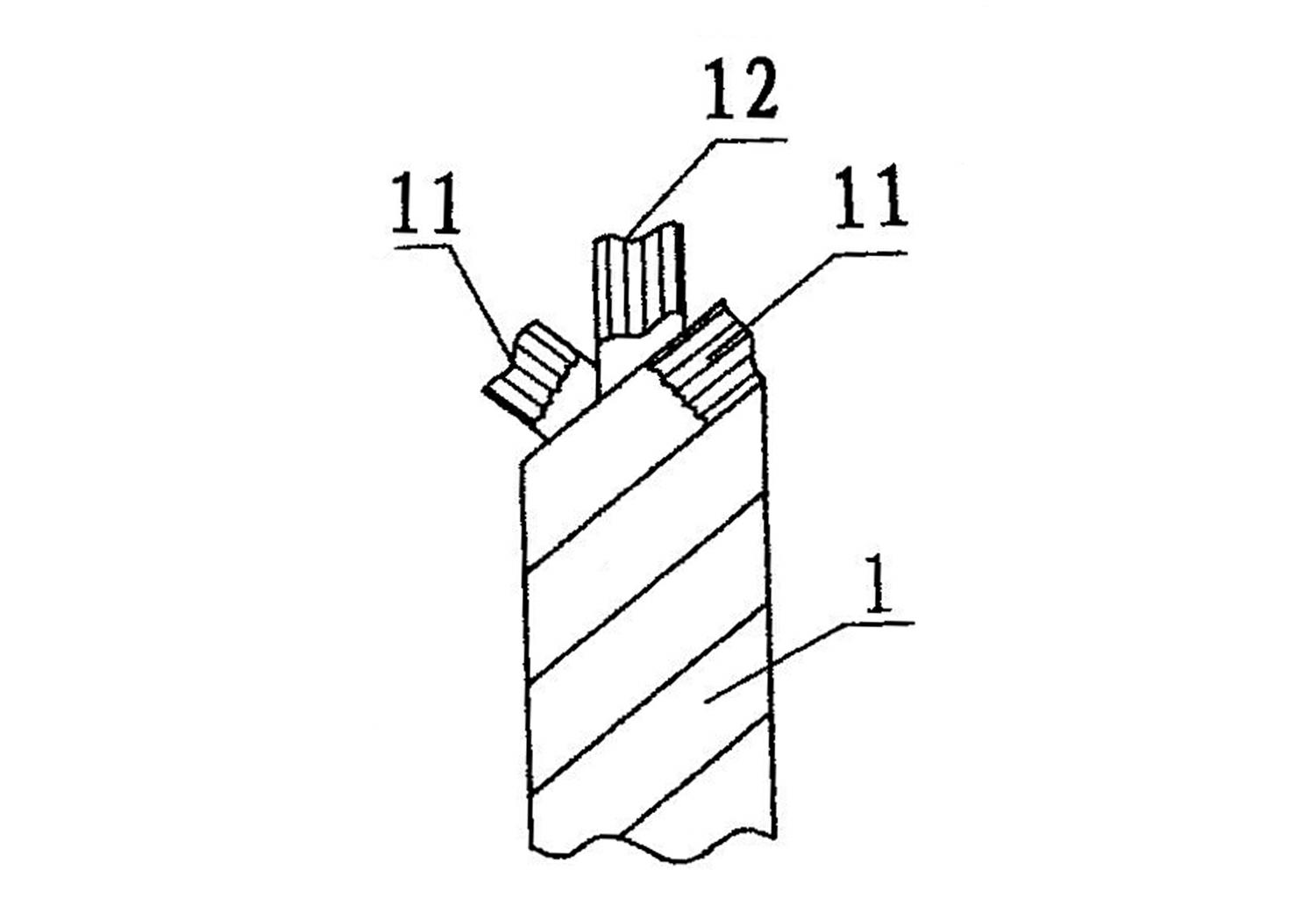

[0020] See figure 2 , two polylactic acid filaments 11 and a biomass spun yarn 12 made of hemp fiber are wound in a spiral shape to form a yarn body 1, and the rest are the same as the description of embodiment 1.

Embodiment 3

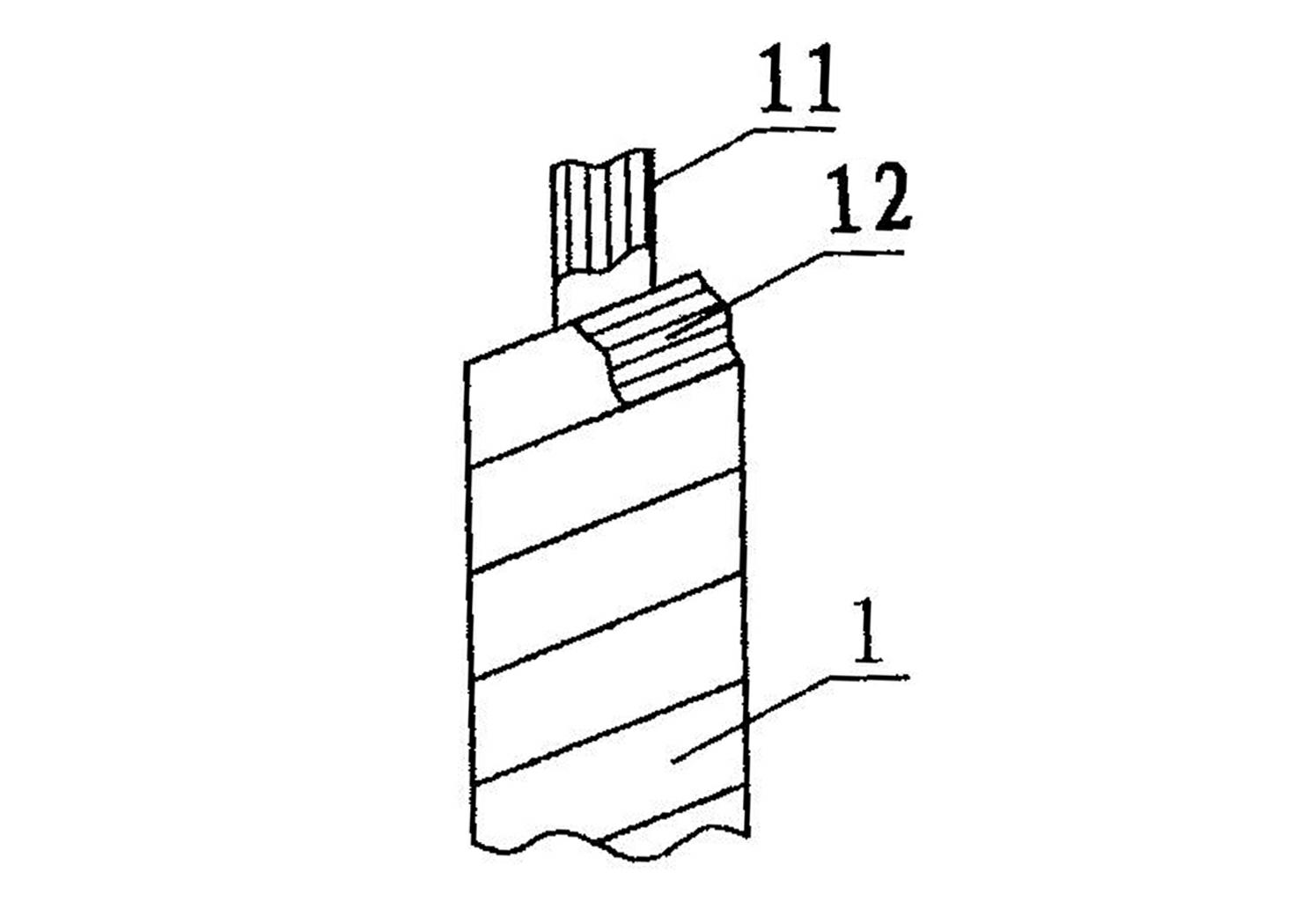

[0022] See image 3 A yarn body 1 is constructed by twisting a polylactic acid filament 11 and a biomass spun yarn 12 made of cashmere fibers in a helical shape. Among them, the polylactic acid filament 11 is polylactic acid elastic filament, and the polylactic acid elastic filament is made of polylactic acid filament multifilament through false twisting, and the rest are the same as the description of embodiment 1.

[0023] The technical solution provided by the present invention is not limited to the above-mentioned three embodiments, for example: two groups of polylactic acid filaments 11 of the same specifications can be respectively used as polylactic acid elastic filaments and the same specifications of cashmere fibers as biomass shorts The yarns 12 are mixed in a helically wound configuration. As another example, you can use figure 1 That is, the raw material of the biomass spun yarn 12 in Example 1 is replaced with a blended fiber of silk cotton and milk silk, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com