Method for measuring positioning points based on laser tracker in docking process of airplane parts

A technology of laser tracker and aircraft components, which is applied in the direction of aircraft component testing, aircraft parts, measuring instruments, etc., and can solve problems such as complex working conditions, dangers, and data measurement fluctuations on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

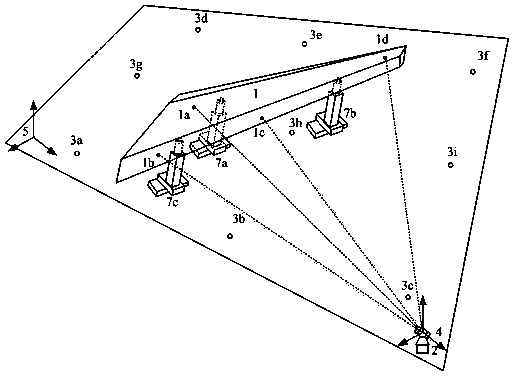

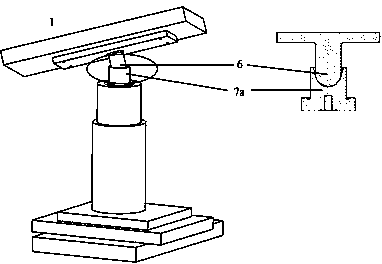

[0051] The laser tracker-based method for measuring positioning points during the docking process of aircraft components includes the following steps:

[0052] Step 1. At the location of the aircraft component docking site, select the TB or ERS point as the public observation point, the public observation point can be measured by the laser tracker, and the number of the public observation point is greater than 7;

[0053] Step 2. Use the laser tracker to measure the coordinates of the public observation points, and obtain the measured coordinates of these points in the laser tracker measurement coordinate system

[0054] Step 3. Combine the target coordinates of the public observation point And measurement coordinates Determine the mapping relationship between the laser tracker measurement coordinate system and the aircraft component global coordinate system; specifically:

[0055] (1) The conversion model function of the mapping between the laser tracker measurement coordinate syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com