Digitalized detection method for temperature information of micromechanical quartz gyroscope sensitive device

A technology of micro-mechanical gyroscope and temperature information, which is applied in the direction of speed measurement, gyroscope/steering sensing equipment, etc., with thermometers and gyro effects that are directly sensitive to heat, and can solve the effects of accuracy, poor consistency, and tuning forks. The nature of Vk is not completely consistent, etc., to achieve the effect of improving real-time performance and accuracy, improving accuracy and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

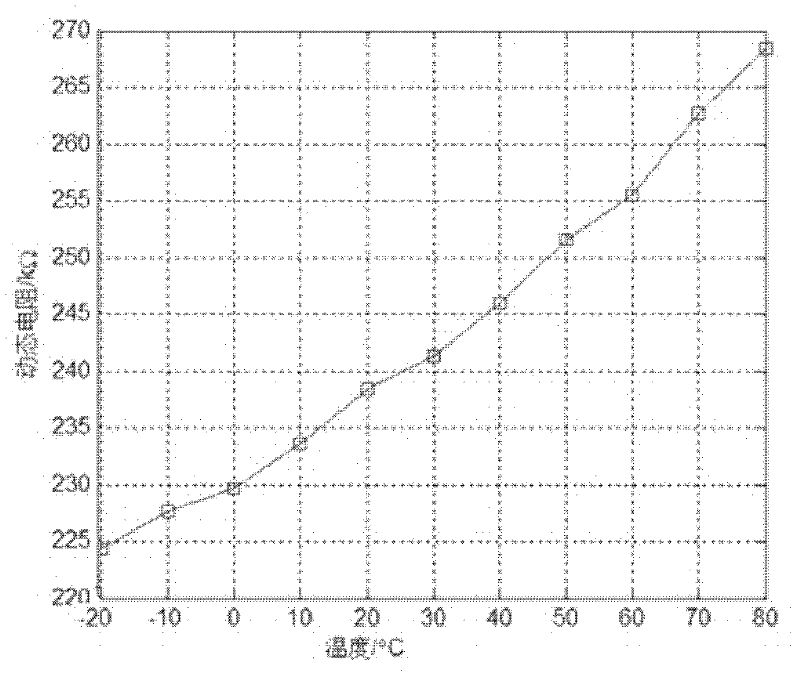

[0085] Using the temperature measurement method of the present invention, in the temperature range of -20 degrees to 80 degrees, the g values at different temperatures were measured, and the formula (13) was used to obtain the first-order, second-order, and third-order fitting respectively. temperature value. Figure 7 , Figure 8 , Figure 9 represent the fitting results, respectively.

[0086] The first-order fitting is expressed as T(g)=p1*g+p2; calculated by the least square method, p1=15.96, p2=8241;

[0087] The second-order fitting is expressed as T(g)=p1*g 2 +p2*x+p3. Calculated by the least square method, p1=0.0385, p2=13.65, p3=8237;

[0088] The third-order fitting is expressed as T(g)=p1*g 3 +p2*g 2 +p3*g+p4. Calculated by the least square method, p1=5.436*10 -8 , p2=-0.001437, p3=12.7, p4=-3.751*10 4 .

[0089] It can be seen from the test results that the effect of the third-order fitting is ideal, that is, the temperature information can be accurate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com