Alkali soluble transparent resin composition

A technology of transparent resin and composition, applied in the field of flexible wiring boards, which can solve the problems of insufficient light transmittance of discoloration resistance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15

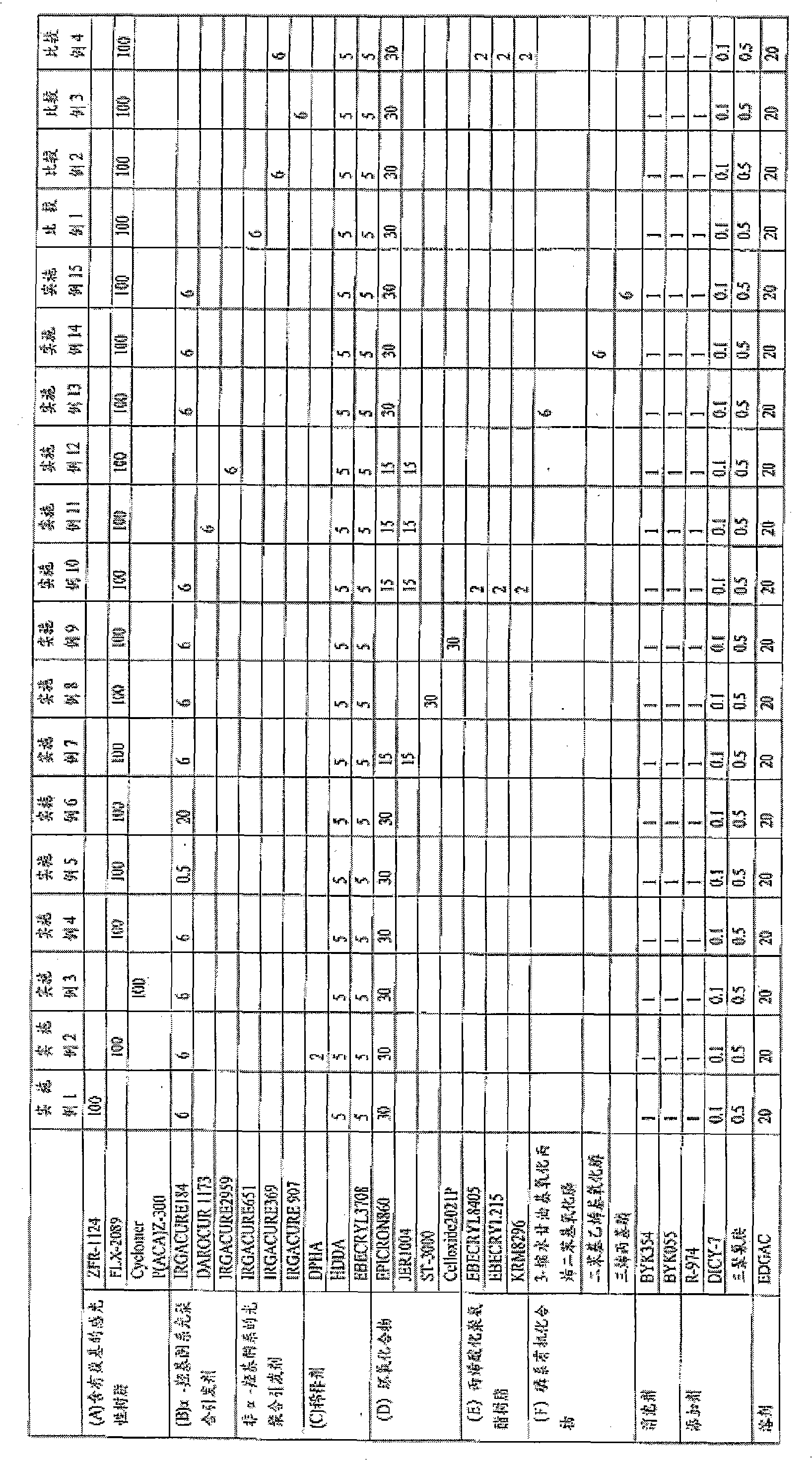

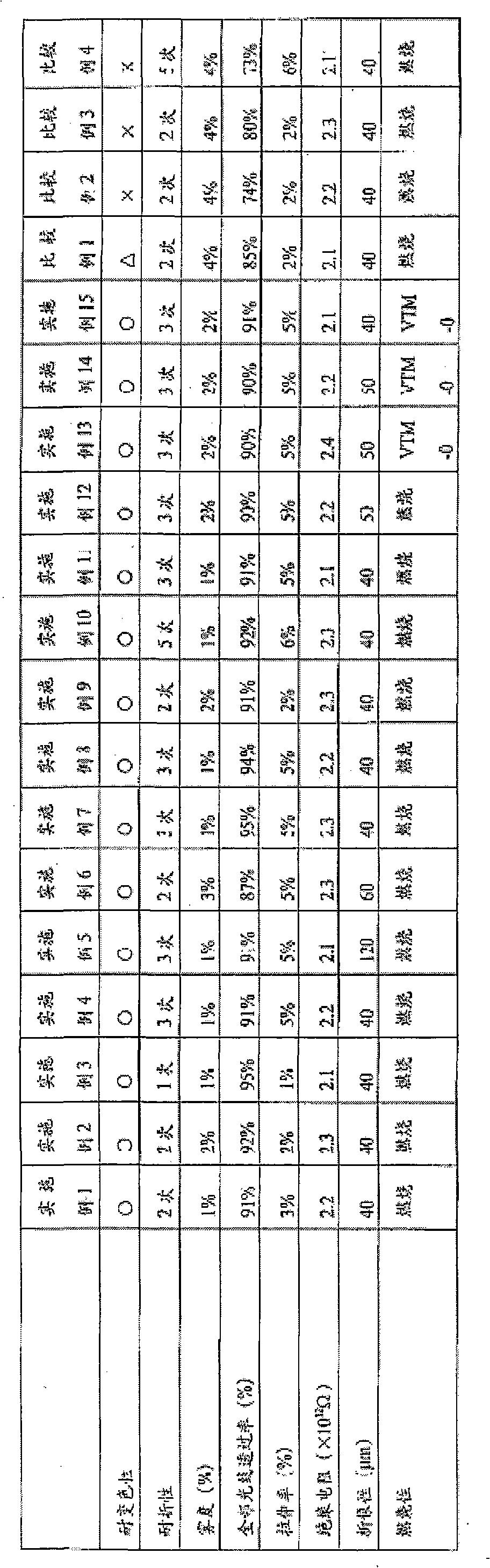

[0060] Examples 1-15, Comparative Examples 1-4

[0061]The components shown in the following Table 1 were mixed according to the compounding ratio shown in the following Table 1, and after pre-mixing with a mixer, they were mixed and dispersed at room temperature using a three-roll mill to prepare Examples 1 to 15 and Comparative Example 1. Alkali-soluble transparent resin composition used in ~4. Then, the prepared alkali-soluble transparent resin composition was applied as follows to prepare a test piece. In addition, the numerical value of the compounding ratio in Table 1 represents a mass part.

[0062] 【Table 1】

[0063]

[0064] In addition, the detail of each component in Table 1 is as follows.

[0065] About (A) Carboxyl group-containing photosensitive resin

[0066] - ZFR-1124: Nippon Kayaku Co., Ltd. product, a carboxyl group-containing photosensitive resin obtained using a polyfunctional epoxy resin having a bisphenol F structure.

[0067] · FLX-2089: manufac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com