Meshed rapid prototyping method

A prototyping and gridding technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as inseparability, and achieve high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

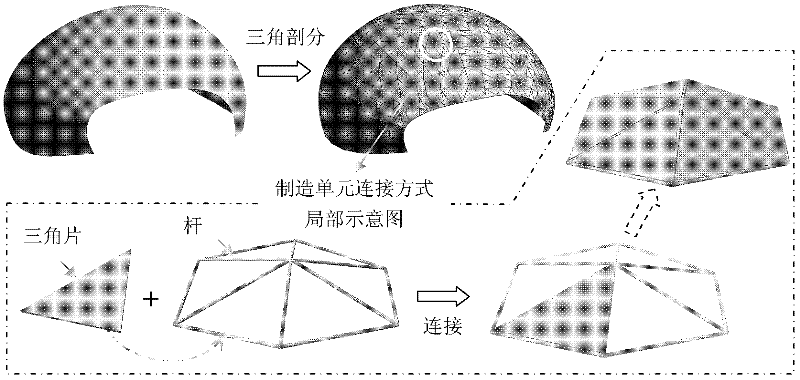

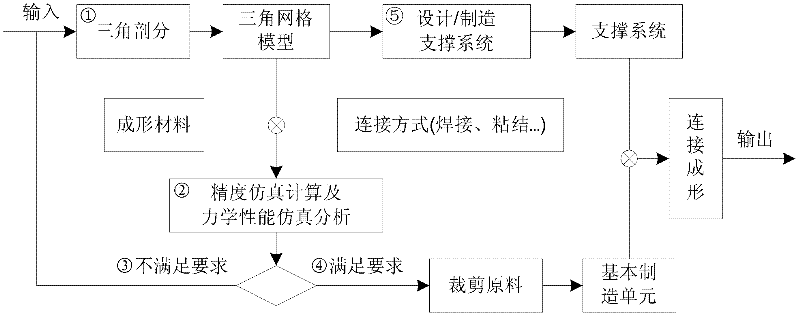

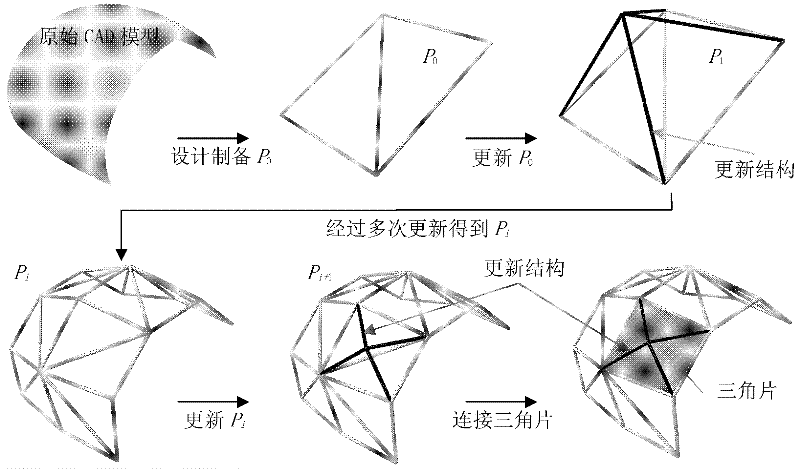

[0035]The meshed rapid prototyping proposed by the present invention is also based on the principle of discrete or stacked forming, and can also be regarded as a rapid prototyping technology; the RP technology in the general sense discretizes the model into a sheet structure, while the meshed rapid prototyping technology The model is discretized into triangular meshes, so there is an essential difference between meshed rapid prototyping and RP technology in the usual sense, which can be regarded as the expansion and perfection of existing RP technology. The grid-based rapid prototyping method can also be regarded as a layered manufacturing method of space surfaces.

[0036] In general, the surface accuracy of RP formed parts directly depends on the thickness of the sheet. Therefore, in order to improve the accuracy of the part, the thickness of the sheet is usually very thin. Limited by the manufacturing principle, the RP forming efficiency of large parts is often relatively lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com