Fiber grating measuring system of vehicle running speeds and positions

A technology of vehicle speed and fiber grating, which is applied in the traffic control system of road vehicles, traffic control systems, instruments, etc., can solve the problem of zero, and achieve the effect of improving durability, sensitive monitoring, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

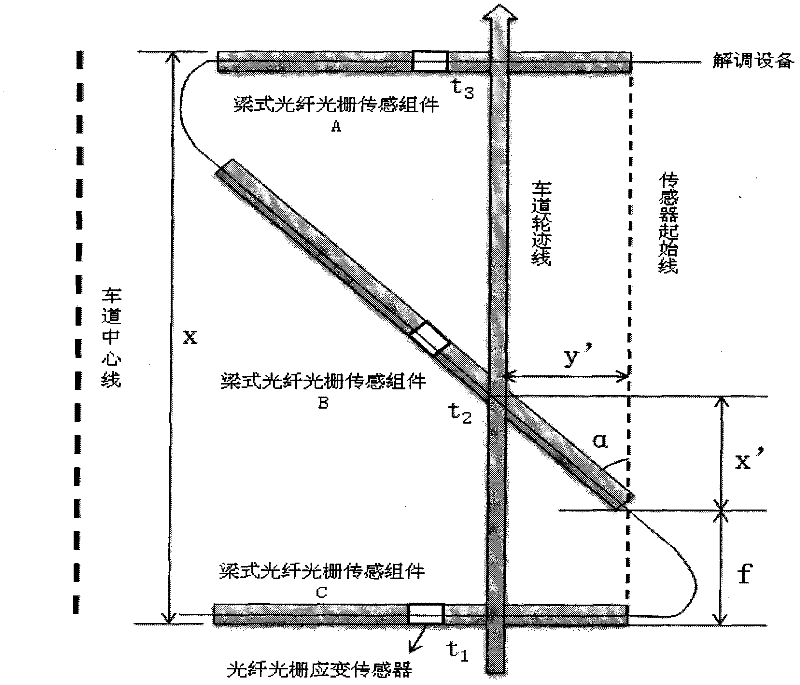

[0010] Example 1: Combining figure 1 , figure 2 , the present invention is a vehicle speed and position fiber grating measuring system, which includes three groups of beam fiber grating sensing components buried under the asphalt concrete or cement road surface, characterized in that: the beam fiber grating sensing component A and The beam fiber grating sensing component C is arranged in parallel, the beam fiber Bragg grating sensing component B is arranged between the beam fiber Bragg grating sensing component A and the beam fiber Bragg grating sensing component C, and the beam fiber Bragg grating sensing component B is oblique The orientation arrangement forms an α angle with the starting line of the sensor, and the α angle is 30° to 60°, and three groups of beam fiber grating sensing components are connected in series.

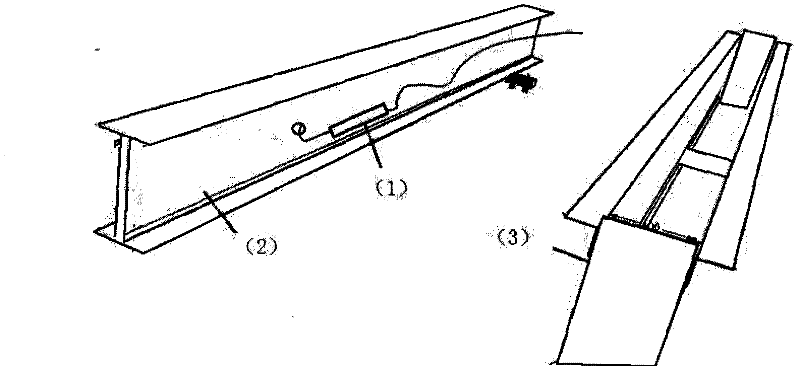

[0011] The present invention also has the following technical features: the beam-type fiber grating sensing assembly is composed of a fiber grating strai...

Embodiment 2

[0012] Example 2: Combining figure 1 , figure 2 , the principle of the vehicle driving position and speed measurement system, combined with figure 1 , the calculation process is as follows:

[0013] v = x t 2 - t 1 - - - ( 1 )

[0014] v = f + x ′ t 2 - t 1 - - - ( 2 )

[0015] x ′ = x t ...

Embodiment 3

[0030] Example 3: Binding figure 1 , figure 2 , the beam fiber grating sensing component A and the beam fiber grating sensing component C are arranged in parallel, the beam fiber grating sensing component B is arranged obliquely to form an angle of α degree with the starting line of the sensor, and connected in series Three sets of beam fiber grating sensing components. When the vehicle passes through the test system, the I-shaped steel beam will be bent and deformed by the gravity of the vehicle, and longitudinal tensile strain will be generated in the lower part of the beam, which is received by the fiber grating strain sensor and transmitted to the demodulator The equipment will generate a waveform diagram and correspond to the corresponding time t1, t2, t3. According to the above formula, calculate the speed of the vehicle and the value of y' from the formula (1) and formula (5), that is, determine the driving position of the car. Bury the beam-type fiber grating sensin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com