Integrated high-voltage power IGBT device monolithic LED driving chip

A high-voltage power device and LED driving technology, applied in the field of integrated circuits, can solve the problems of complex peripheral circuits and high overall cost, and achieve the effect of ensuring high performance and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

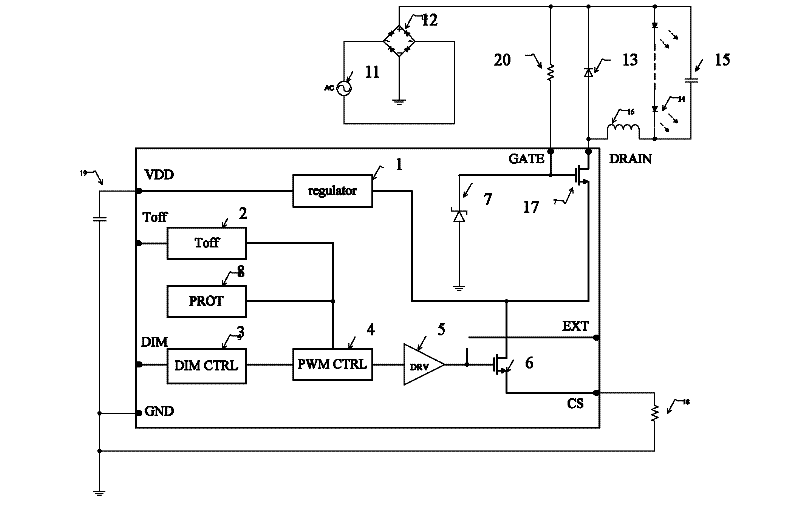

[0009] The overall application scheme of the present invention consists of an LED driver chip and its peripheral circuits. The LED driver IC consists of a regulator linear regulator 1, a Toff off-time timer 2, a DIM dimming controller 3, a PWM signal generator 4, a DRV power tube driver module 5, a low-voltage power device 6, and a gate of an external high-voltage power device The setting circuit 7, the high-voltage power tube 17, and the protection circuit 8 are composed, and the protection circuit 8 includes a load open-circuit short-circuit protection circuit, an over-current protection circuit and an over-temperature protection circuit. The peripheral circuit is composed of a standard full-bridge rectifier circuit 12 , high-voltage input BUCK step-down circuits 13 , 14 , 15 , 16 , and a sampling resistor 18 .

[0010] The LED driver IC drives the internal low-voltage power device 6 in a fixed off-time control mode, and its fixed off-time is determined by Toff off-time time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com