Method for improving segregation and shrinkage of center of square and round billet

A technology of center shrinkage cavity and segregation, which is applied in the solidification process of rectangular billet continuous casting and round billet continuous casting, to improve the central segregation and shrinkage cavity of continuous casting billet, and in the field of square billet continuous casting, it can solve the problem of insufficient stability of control improvement effect and cost High-level problems, to achieve the effect of improving implementation efficiency, expanding horizontal area, and stabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

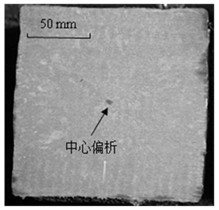

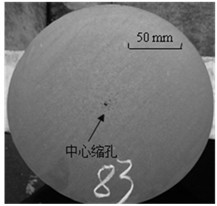

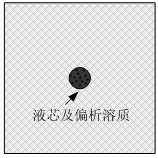

[0043] During the continuous casting process, the slab gradually solidifies from the outside to the inside. Since the solubility of the segregated solute elements in the continuous casting slab in the liquid phase is greater than that in the solid phase, the segregated solute elements in the steel are easily enriched to the liquid core in the center of the slab during the solidification process. Therefore, there are relatively few segregated solute elements in the primary slab shell outside the cast slab, but relatively more in the final solidification area inside, and even a large amount of enrichment occurs, resulting in central segregation. At the end of solidification of the slab, the solid phase rate of the liquid core is high, and the flow of molten steel is difficult; the solidification speed at the end of the solidification is fast, and the growth of adjacent dendrites causes a "bridge", preventing the molten steel from flowing to the steel under the bridge. Timely rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com