Automatic straight seam welding machine

A straight seam welding, automatic technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of difficult to guarantee the welding seam width, unstable welding quality, unstable spot welding quality and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with embodiment.

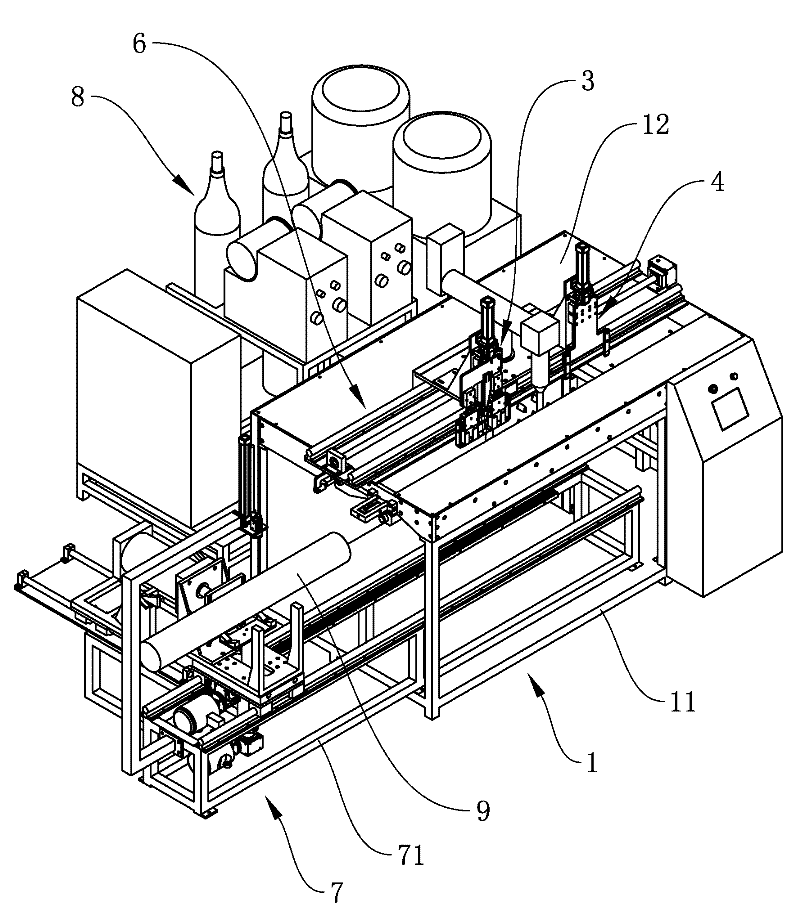

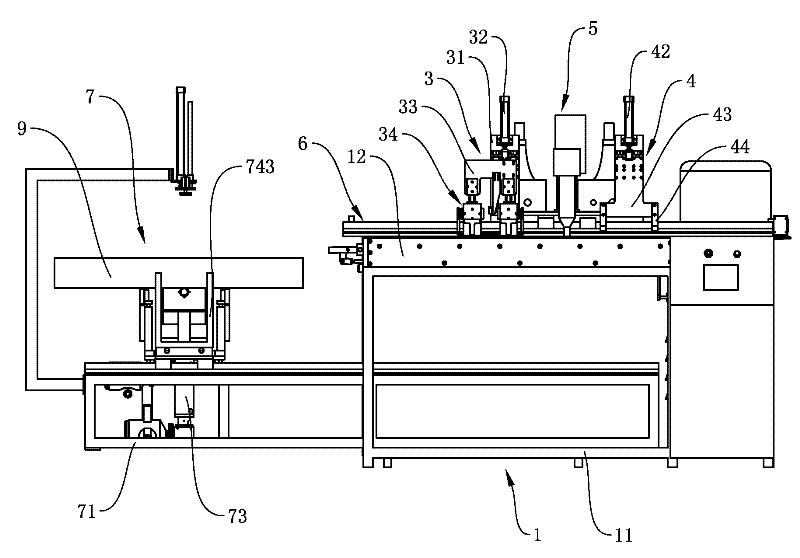

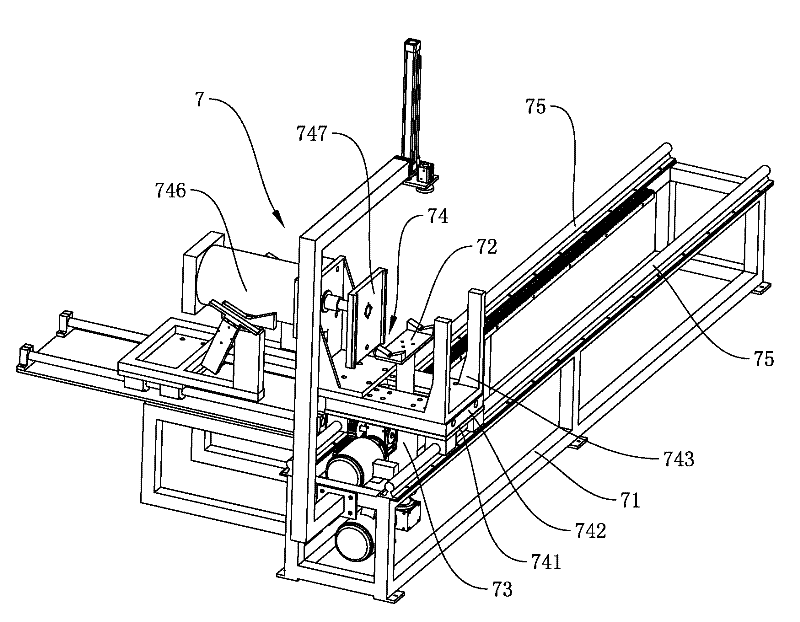

[0052] Such as Figure 1 to Figure 13 As shown, an automatic straight seam welding machine includes a frame 1. The frame 1 includes a leg 11 and a workbench 12 fixed on the upper part of the leg 11. The lower part of the workbench 12 is equipped with a positioning and clamping device 2 for working The upper part of the table 12 is equipped with a straight seam welding device. The straight seam welding device includes a spot welding arc starting part 3, a welding seam positioning part 4 and a submerged arc welding part 5. The workbench 12 corresponds to the spot welding arc starting part 3 and the welding seam positioning Part 4 and submerged arc welding part 5 are provided with a lateral moving device 6 that can move along the weld seam. Corresponding to the positioning and clamping device 2, an automatic feeding device 7 can be arranged horizontally and movablely. The attachment d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com