Manufacture method of cold-rolled roller

A manufacturing method and technology for cold rolls, applied in the field of roll manufacturing, can solve the problems of reducing roll wear resistance, increasing manufacturing costs, failing to achieve goals, etc., to reduce roll changes, improve quality, and ensure continuity and compactness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

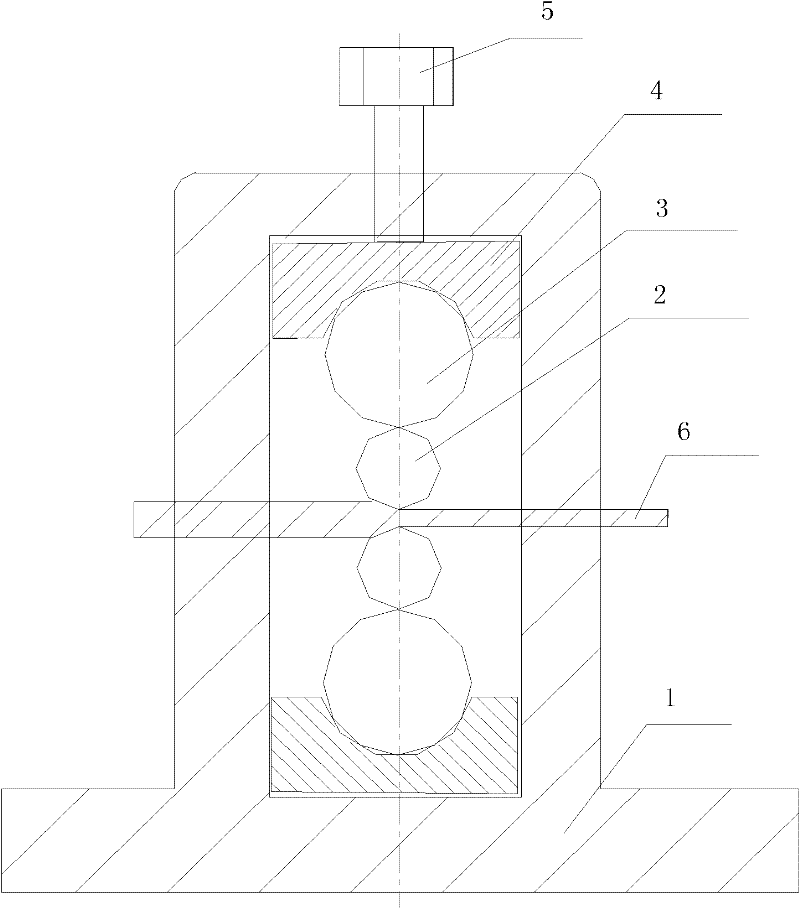

Image

Examples

Embodiment Construction

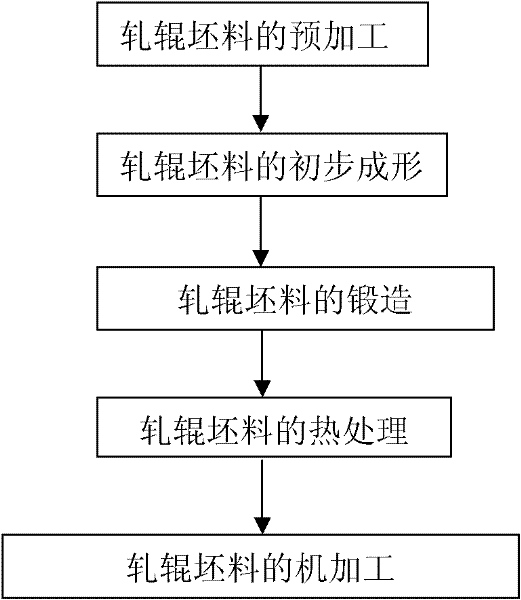

[0073] Such as image 3 As shown, the manufacturing method of the cold-rolled roll of the present invention can control the network carbide in the roll to make it reach the required level, that is, for a forged roll blank with a diameter ≤ Φ650mm, the network carbide ≤ 2.5 grade; diameter > Φ650mm For the roll blank, the carbide should be ≤3.0 grade;

[0074] Include the following steps:

[0075] The first step is the preprocessing of the roll blank;

[0076] After electric furnace smelting-refining furnace refining-vacuum degassing-casting steel ingot (or electroslag remelting steel ingot)-steel ingot heating-steel ingot upsetting-drawing-elongation-blanking, the preprocessing of the roll blank is realized;

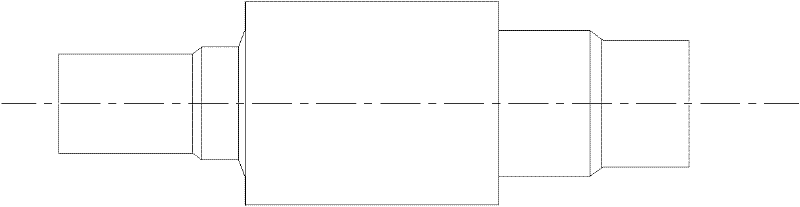

[0077] The second step is the preliminary forming of the roll blank;

[0078] In the preliminary forming process, the diameter of each part of the roll blank is more than the size of the finished product, leaving a certain margin;

[0079] According to the different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com