Self-locking adjusting device and method for using same

An adjustment device and self-locking technology, applied in the field of mechanical processing, can solve problems such as difficult to guarantee accuracy, cumbersome operation, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

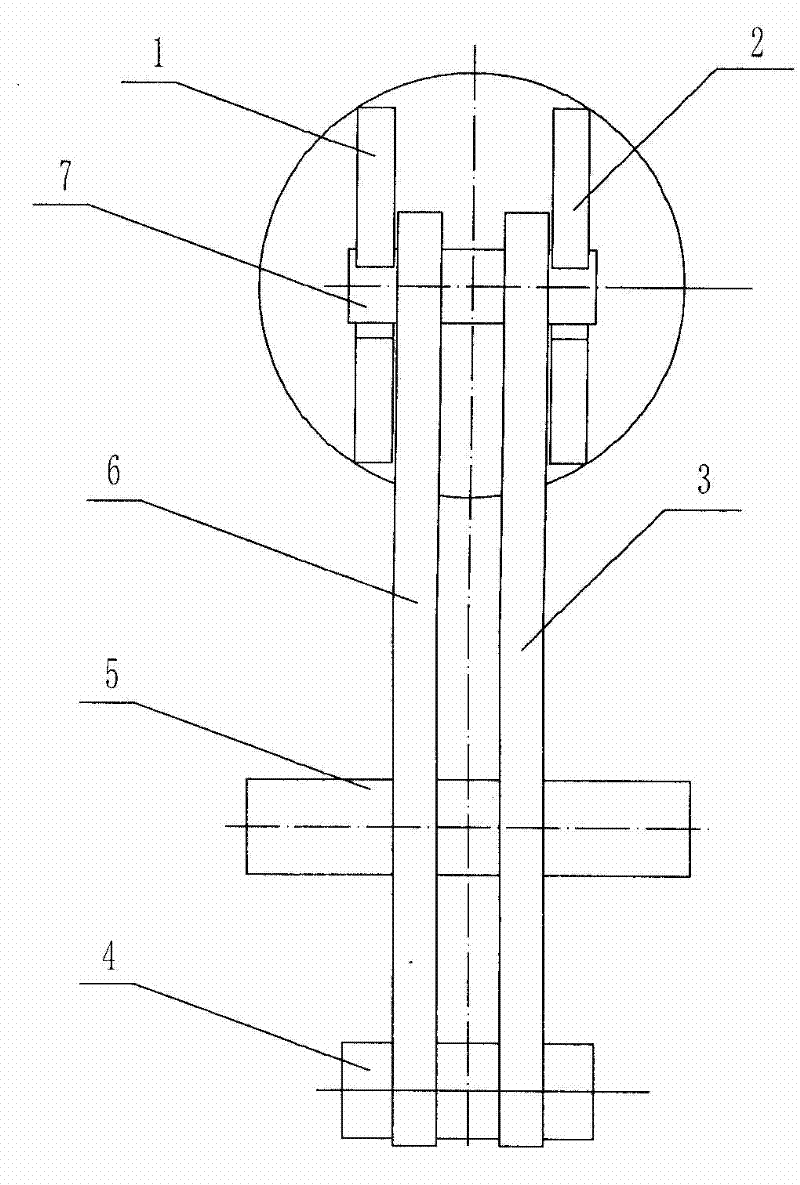

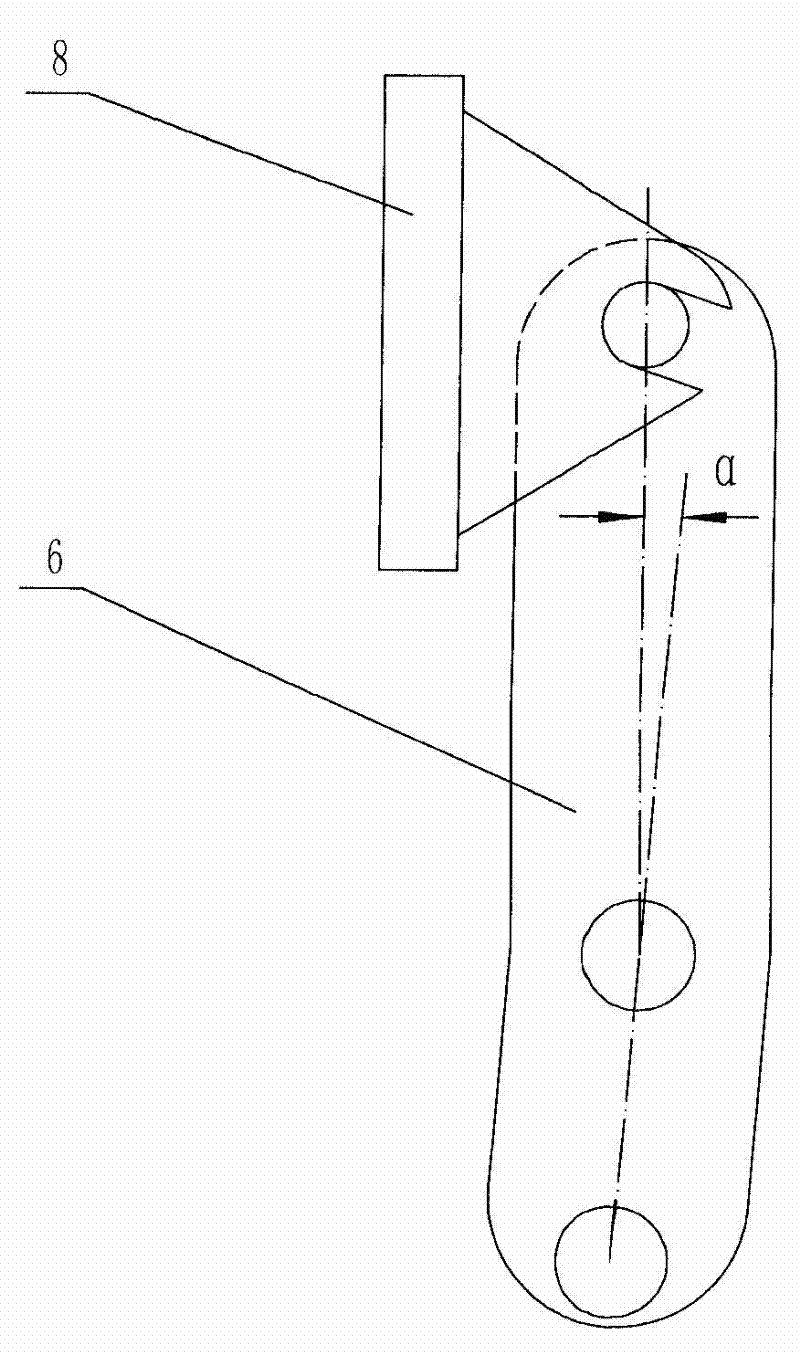

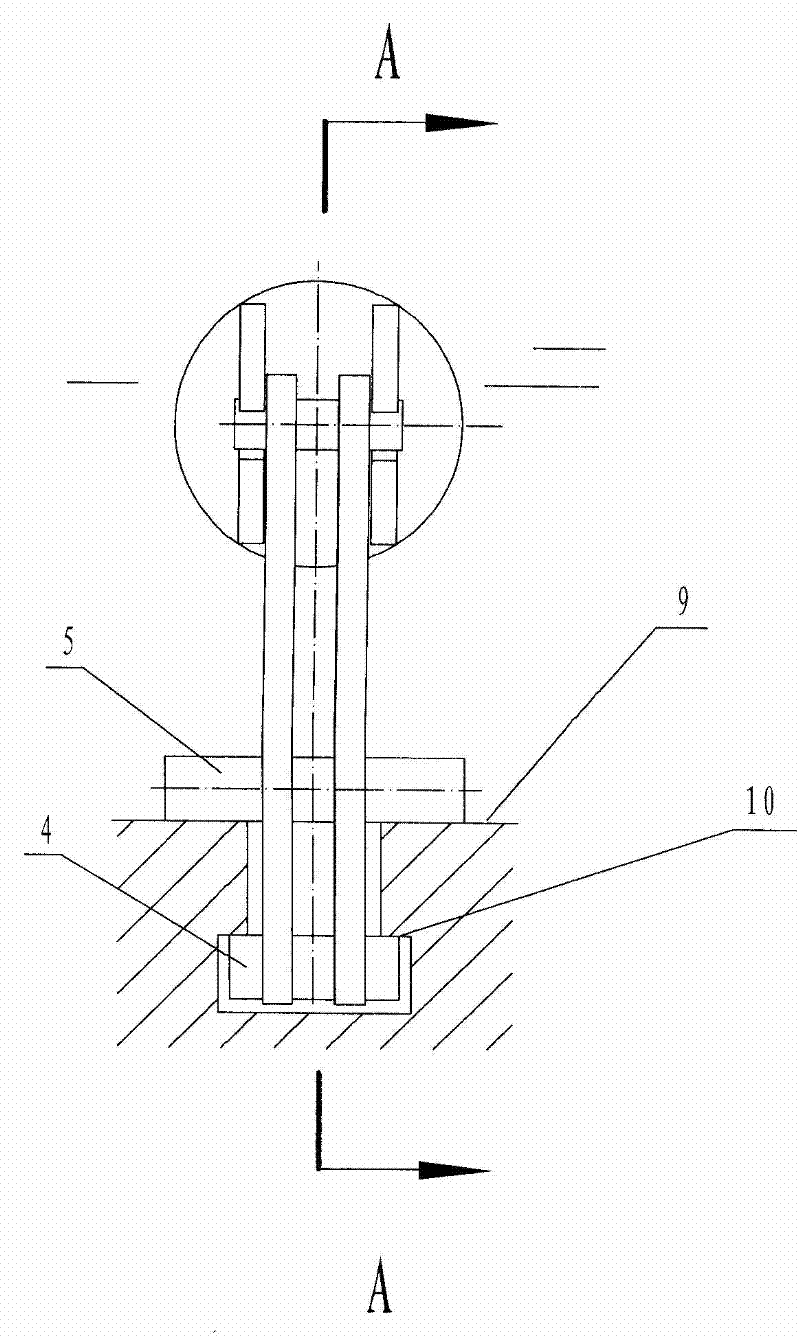

[0025] Such as figure 1 , 2 As shown, the self-locking adjustment device mainly includes a lever arm and a top seat, and the lever arm is composed of mutually parallel support plates A 6, support plates B 3 and pin shafts connecting the two support plates, support plates A, The lower part of the support plate B is bent inward, and the upper part, the bent part and the lower part of the two support plates are respectively provided with pin hole A, pin hole B and pin hole C, and the pin shaft A 7, the pin shaft B 5 and the pin shaft C 4 are respectively pierced In the pin hole A, pin hole B, and pin hole C of the two support plates and welded together with the support plate; Composition, one side of the connecting plate is provided with a notch matching with the pin shaft A; the pin shaft A is pierced through the notche...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com