Main transmission clearance eliminating mechanism of mechanical servo numerical control turrent punch press

A CNC turret punch press and mechanical servo technology, which is applied to metal processing machinery parts, driving devices, metal processing equipment, etc., can solve problems such as unstable transmission and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

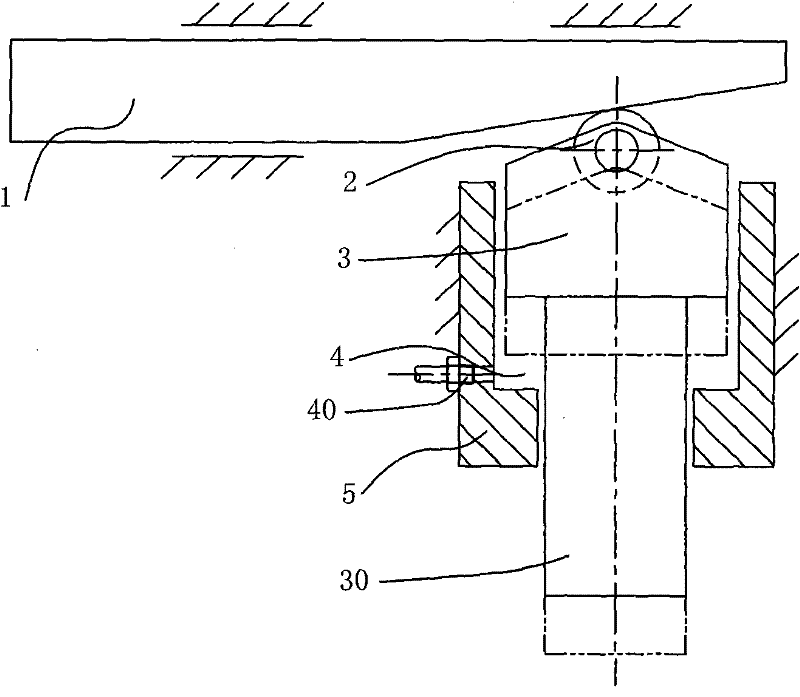

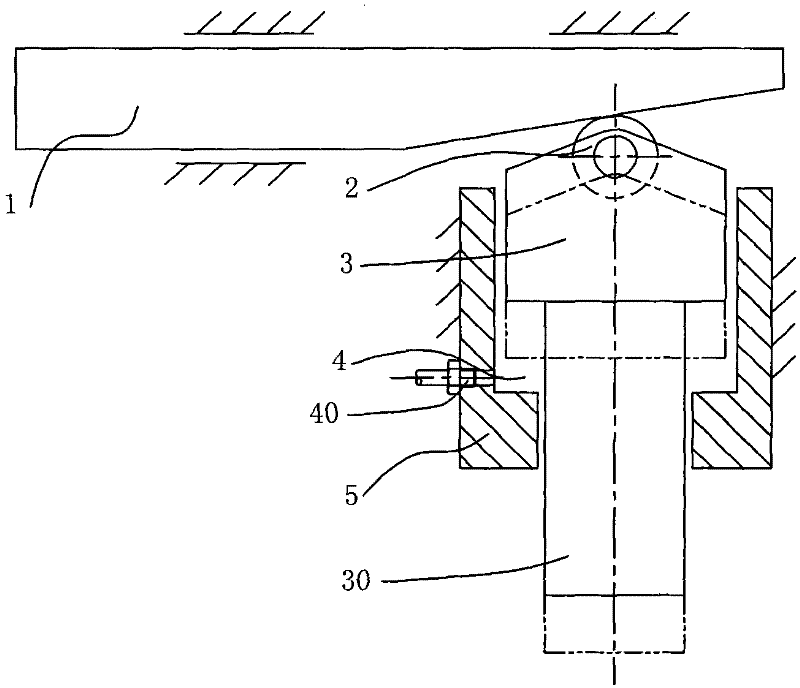

[0011] The present invention as figure 1 As shown, it includes an inclined block 1 horizontally slidably connected to the fuselage and a strike head movably connected to the fuselage perpendicular to the horizontal plane. The percussion head body 30; also includes a cylindrical fixed seat 5 with an open upper part, the fixed seat 5 is fixedly connected to the fuselage, and the bottom surface of the fixed seat 5 is provided with a middle hole; the inner diameter of the fixed seat 5 is the same as The head part 3 of the striking head is airtightly matched, and the middle hole on the bottom surface of the fixing seat 5 is airtightly fitted with the striking head body 30 .

[0012] The height of the inner cylinder of the fixing base 5 is greater than the height of the striking head 3 . Thereby an air cavity 4 is left in the lower part of the inner cavity of the fixed seat 5 .

[0013] It also includes an air hole 40 and an air source, the air hole 40 is arranged on the side wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com