Hydraulic former for plain film-coated building circular template

A technology of forming machine and round formwork, applied in the direction of wood compression, etc., can solve the problems of difficult control of product quality and size standards, large influence of human factors of round formwork, poor surface flatness of finished products, etc., so as to improve product quality and reduce construction costs. , the effect of good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

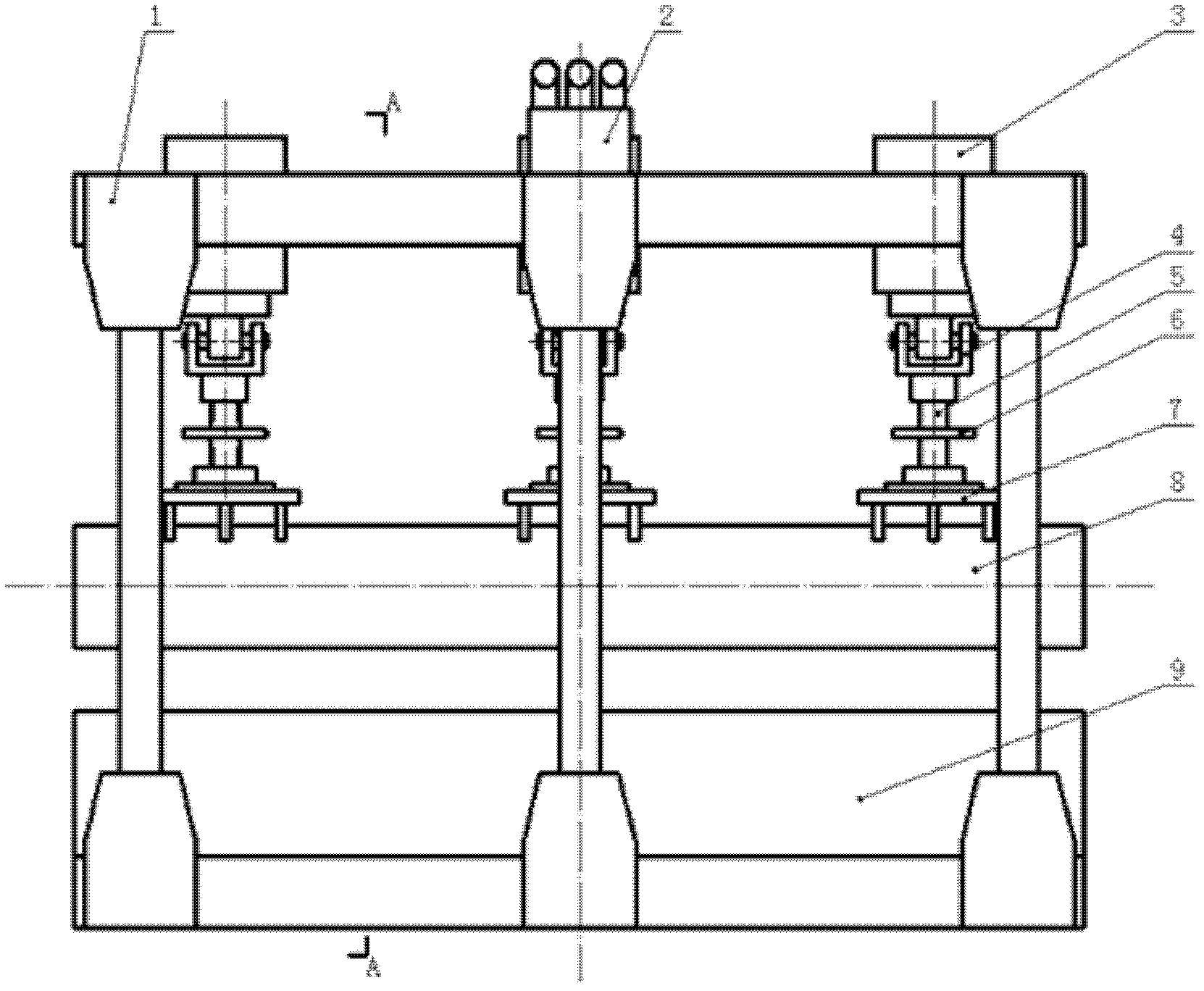

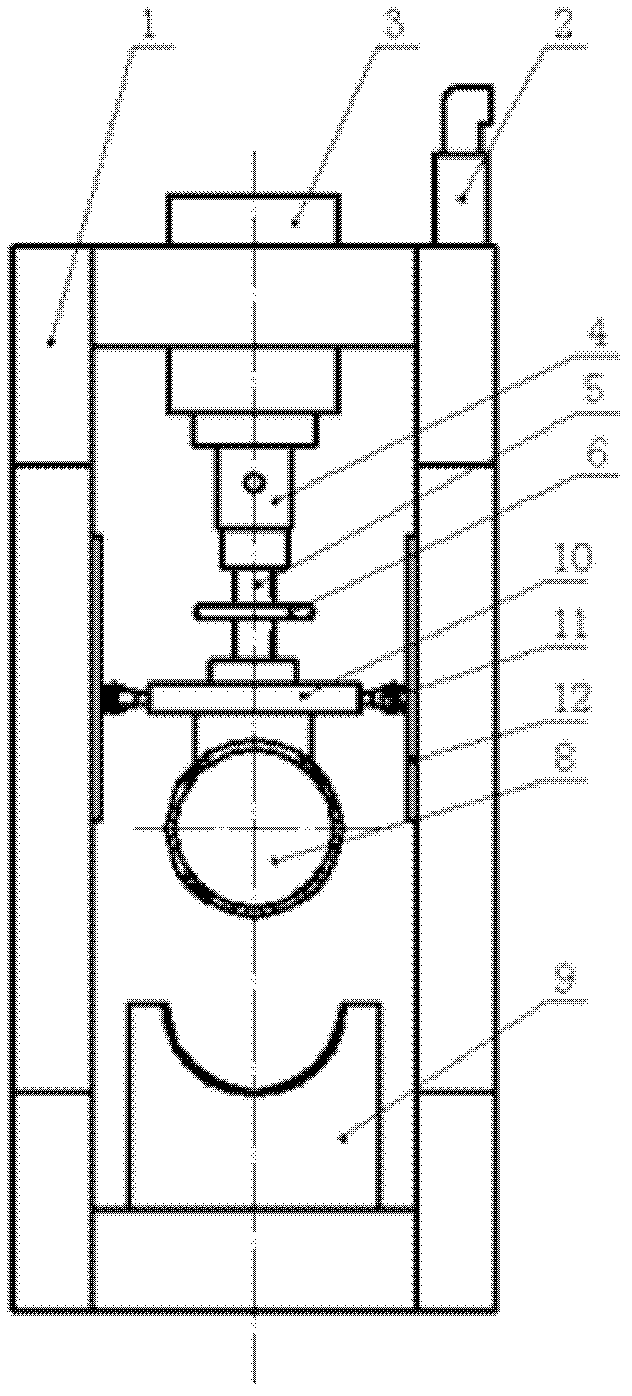

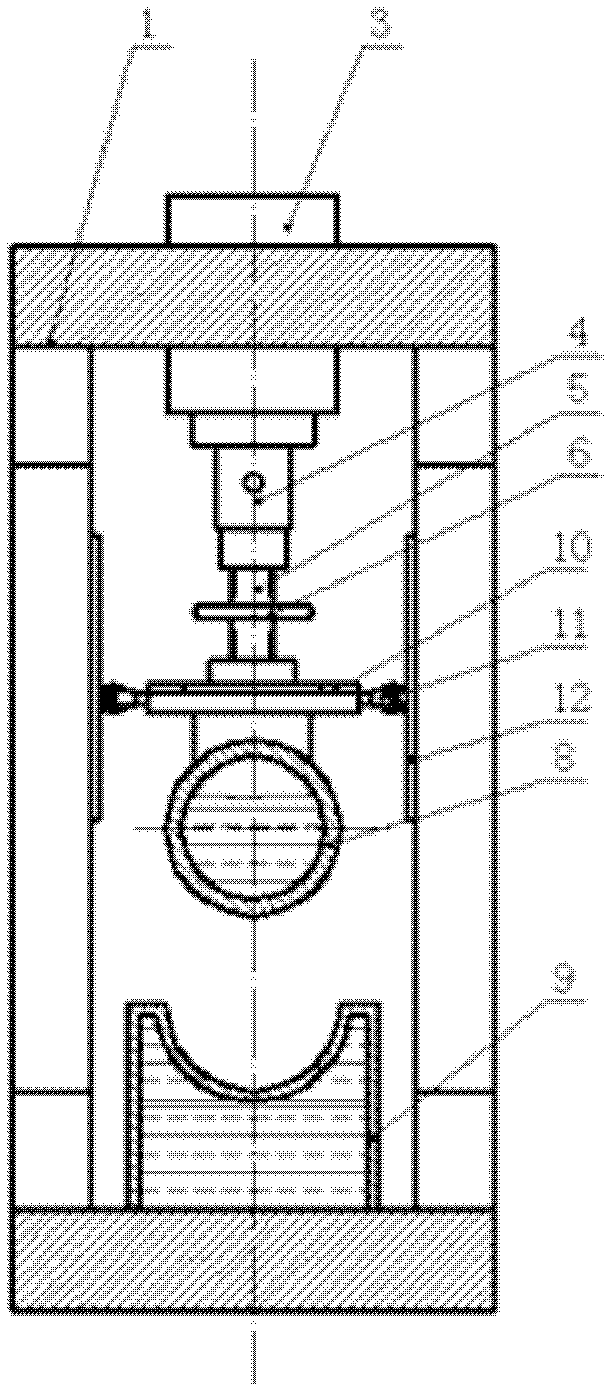

[0027] A hydraulic forming machine for clear water film-coated building circular formwork, comprising a square frame frame 1, a hydraulic cylinder 3 is installed at the upper end of the frame, a punch 8 is installed at the lower end of the hydraulic cylinder in the frame, and a punch 8 is installed at the lower end of the frame corresponding to the punch There is a concave mold 9 fixedly installed, both the convex mold and the concave mold have a hollow structure, and there is a hot liquid medium inside, through the continuous high temperature convex mold and concave mold, the processing and forming effect is improved, and the rebound of the round template after forming is avoided, and the product qual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com