Method and device for improving foaming process of refrigerator body or refrigerator door body

A technology for a box and a refrigerator is applied in the field of improving refrigerator box or door foaming, which can solve the problem of lowering the yield of refrigerator box production, and achieve the effects of increasing the yield and improving the exhaust effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

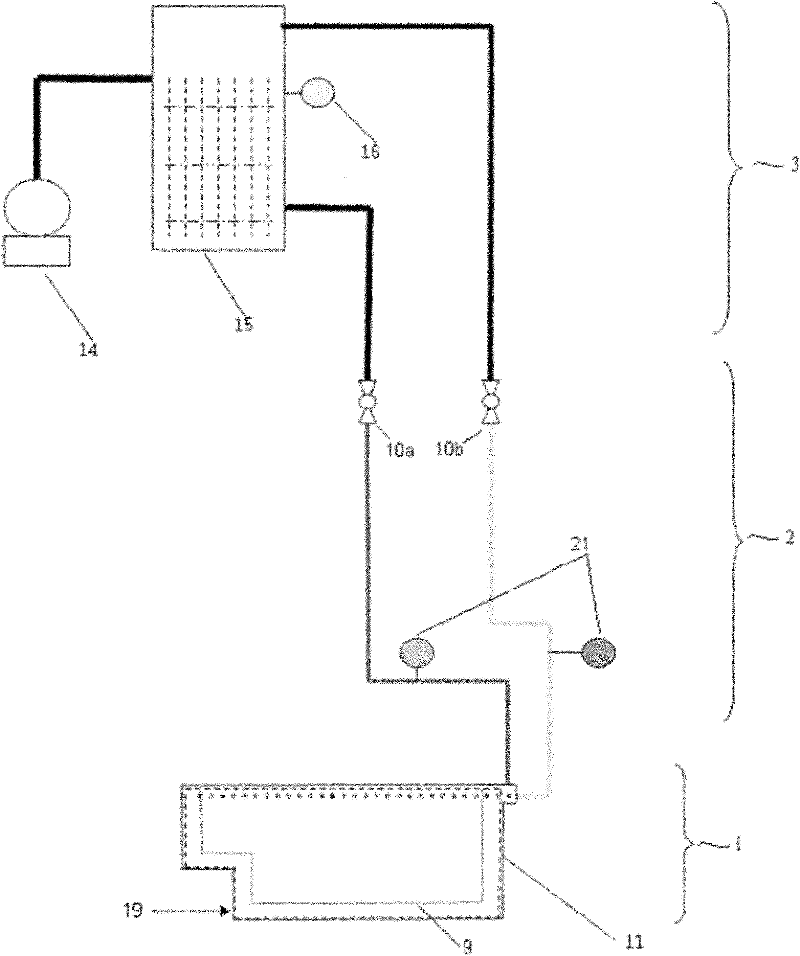

[0027] Figure 1-6 It is a schematic diagram of the foaming device of the refrigerator box.

[0028] Described foaming device is made up of foaming unit 1, pressure control unit 2, decompression device 3 and the pipeline that connects them, as figure 1 shown.

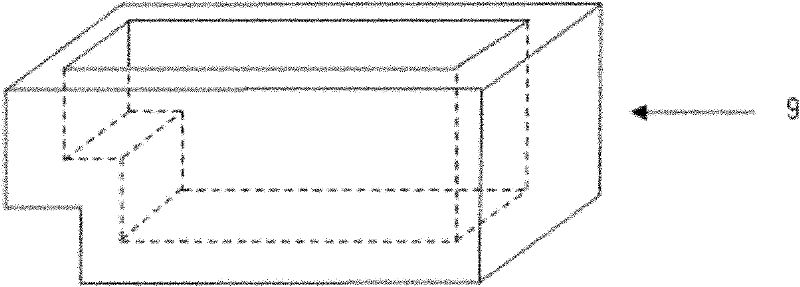

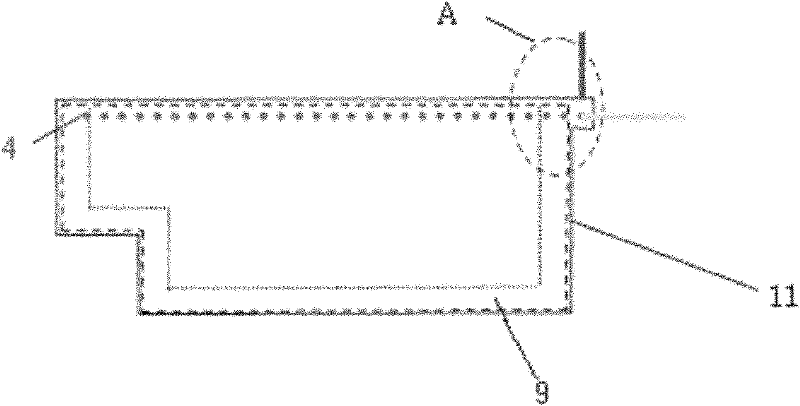

[0029] Wherein, the foaming unit 1 is composed of a mold 11 , a pre-foamed body 9 and an air duct 4 . The pre-foam body 9 is surrounded by an inner container 12 and an outer shell 13 . The mold is provided with a hollow protruding part 5 at a corner of the far end corresponding to the foaming raw material filling, and as an exhaust groove, an exhaust pipe 6 is arranged in the exhaust groove, and the air guide pipe 4 passes through the exhaust pipe 6 and the lower vacuum. The first pipeline 17 of high vacuum degree is connected, and the protruding part 5 is connected with the second pipeline 18 of higher vacuum degree. The pressure control unit 2 consists of pressure gauges 21a, 21b, valves 10a, 10b and connected pip...

Embodiment 2

[0043]The rest are the same as embodiment 1, the difference is that this embodiment is the embodiment that the door body of the refrigerator is foamed. Fig. 7 is a schematic diagram of a refrigerator door foaming unit. The mold is composed of an upper clamp 12 and a lower clamp 13, and a sealing material 24 is provided at the junction of the upper and lower clamps. The pre-foam 9 of the refrigerator door body is placed in the mould, and the pre-foam 9 is provided with an air duct 4, and the foaming material is injected by the injection port 19. A hollow protruding portion 5 is provided on the upper clamp of the mold at a corner of the far end corresponding to the filling of the foaming raw material, and as an exhaust groove, the protruding portion 5 is connected to the second pipeline 18 of a higher vacuum degree, and the air guide pipe 4 and A first duct 17 of lower vacuum is connected and extends out of the mould. The space between the pre-foamed body and the mold and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com