Drive axle of electronic forklift

A technology for electric forklifts and drive axles, which is applied to axles, wheels, brakes, etc. It can solve problems such as poor economy, low mechanical efficiency, and complex structure, and achieve good braking performance, long service life, and high transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

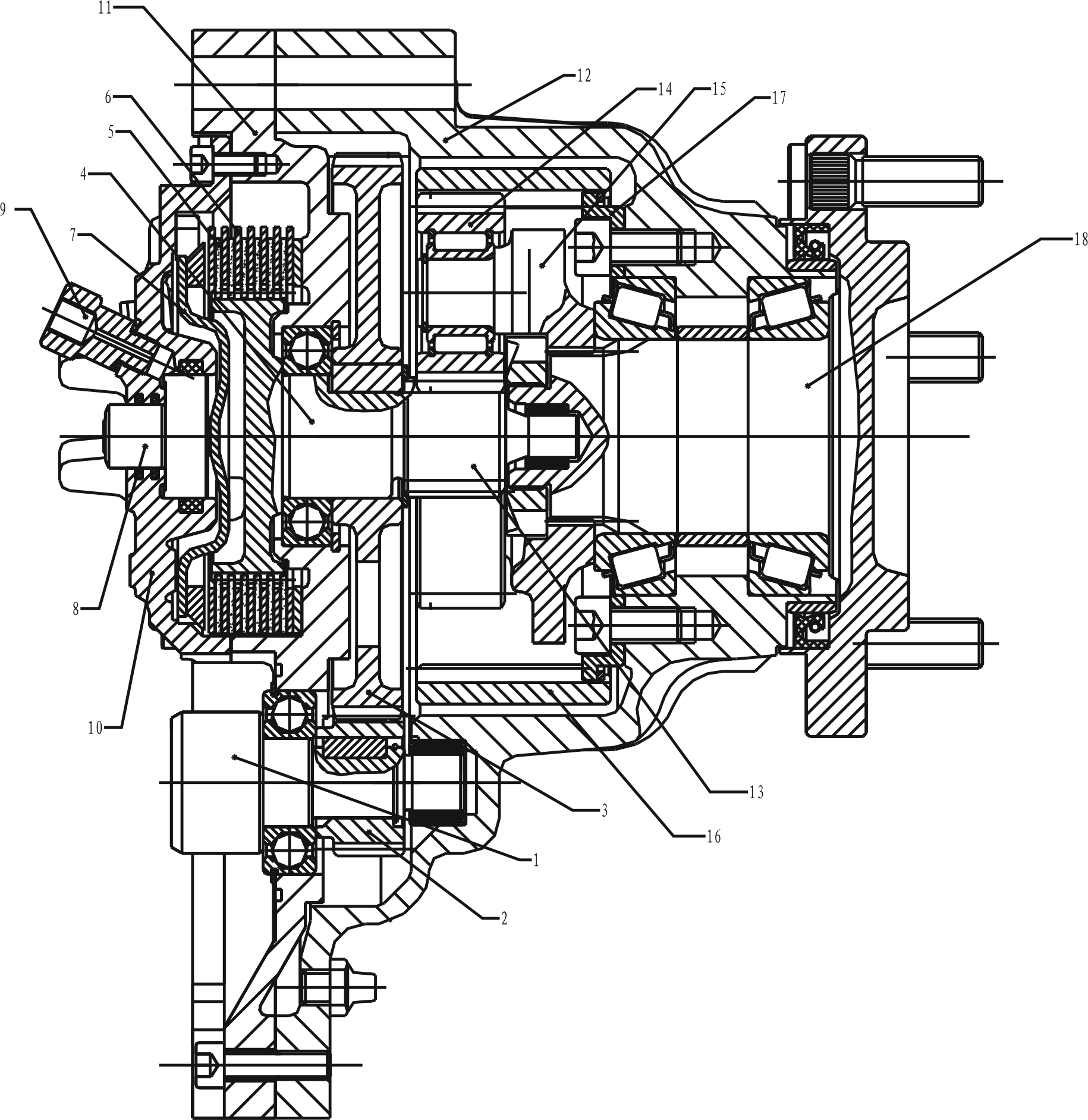

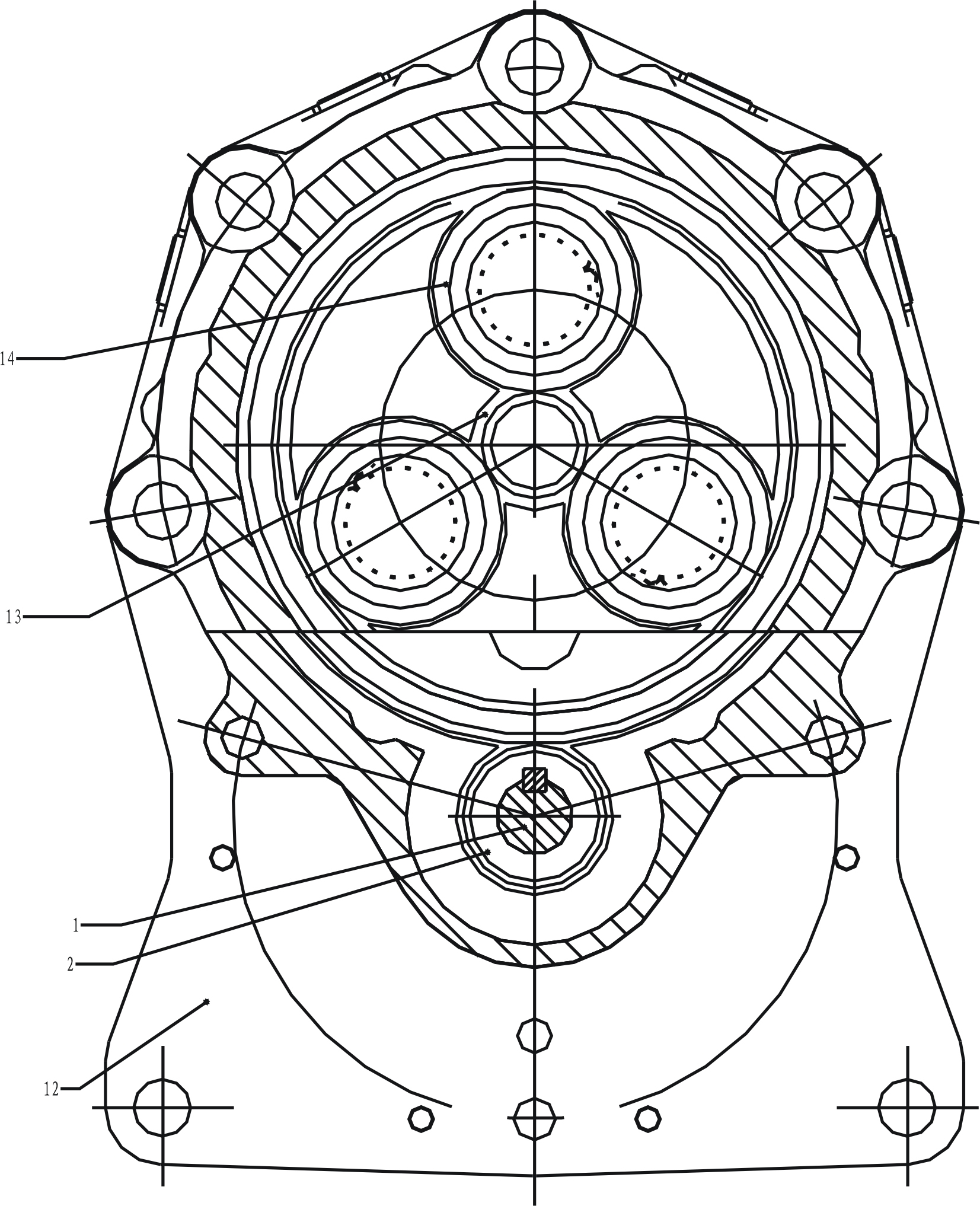

[0027] The content of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] combine figure 1 and figure 2 As shown, the forklift drive axle includes the axle housing assembly, the primary reducer installed in the axle housing assembly, the secondary reducer installed in the axle housing assembly, brakes and hubs;

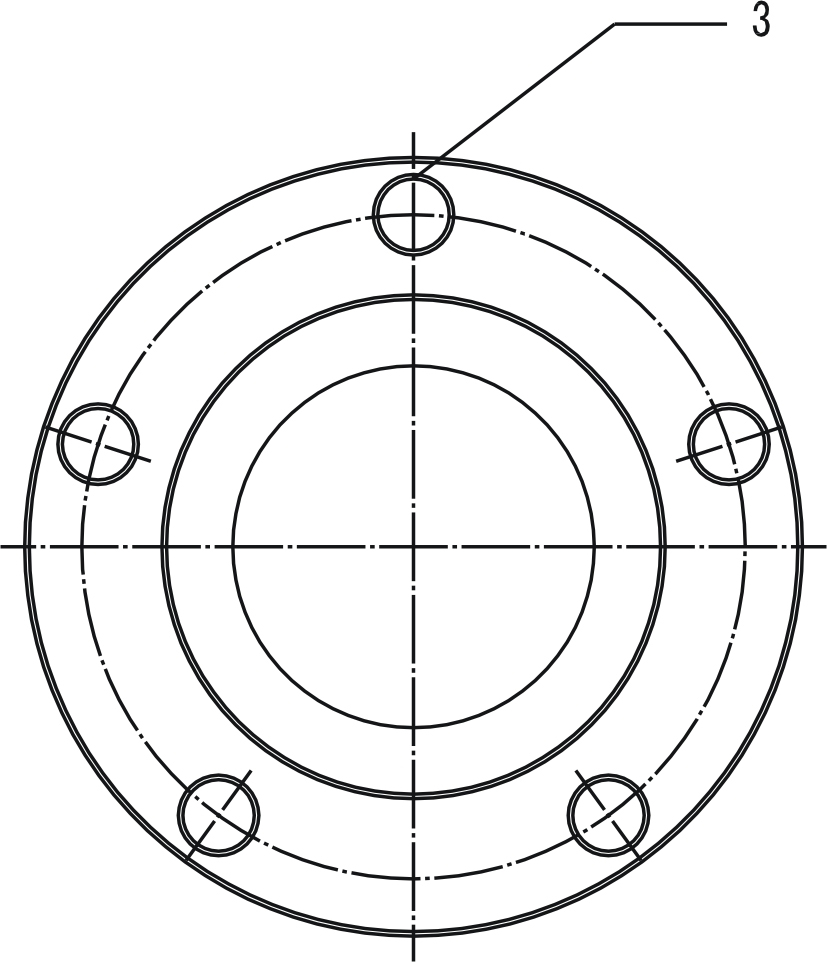

[0029] The axle housing assembly includes an axle housing and an axle cover. The axle housing 12 is open at one end and is connected with the bridge cover 11 by bolts. Tapered roller bearing, supporting hub 18;

[0030] One end of the hub is a stepped hub shaft with a thin front and a thick rear, and the other end is a connecting flange. The large-diameter front end of the stepped hub shaft is provided with an external spline 18-1, and the small diameter of the stepped hub shaft is An external thread 18-6 is provided, which is connected with a lock nut and is used to fix the planet carrier. The end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com