Thrust wheel for heavy-duty railway wagons and bogie thereof

A bogie and roller technology, which is applied in the direction of the lateral relative movement between the railway car body parts, the underframe and the bogie, transportation and packaging, etc. Improve the running quality and other issues to achieve the effect of improving the ability to withstand thermal loads, increasing the braking heat capacity, and shortening the braking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A track wheel and bogie for a heavy-duty railway vehicle according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same components will be described with the same reference numerals.

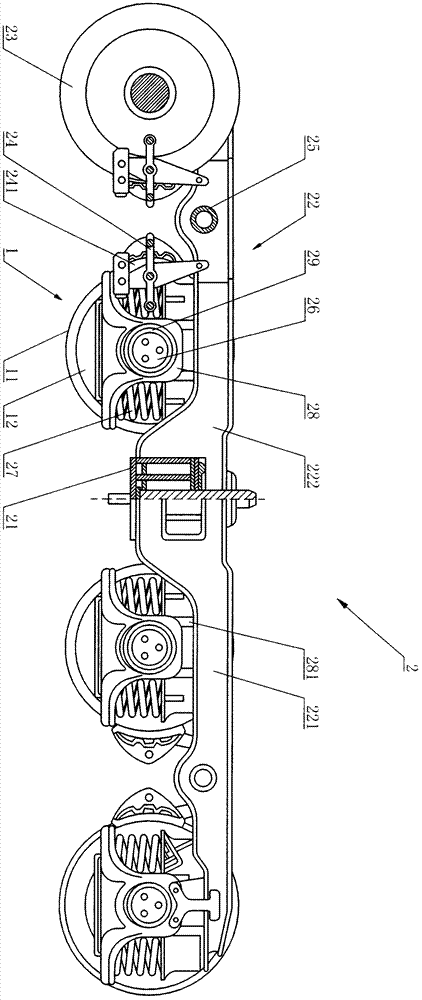

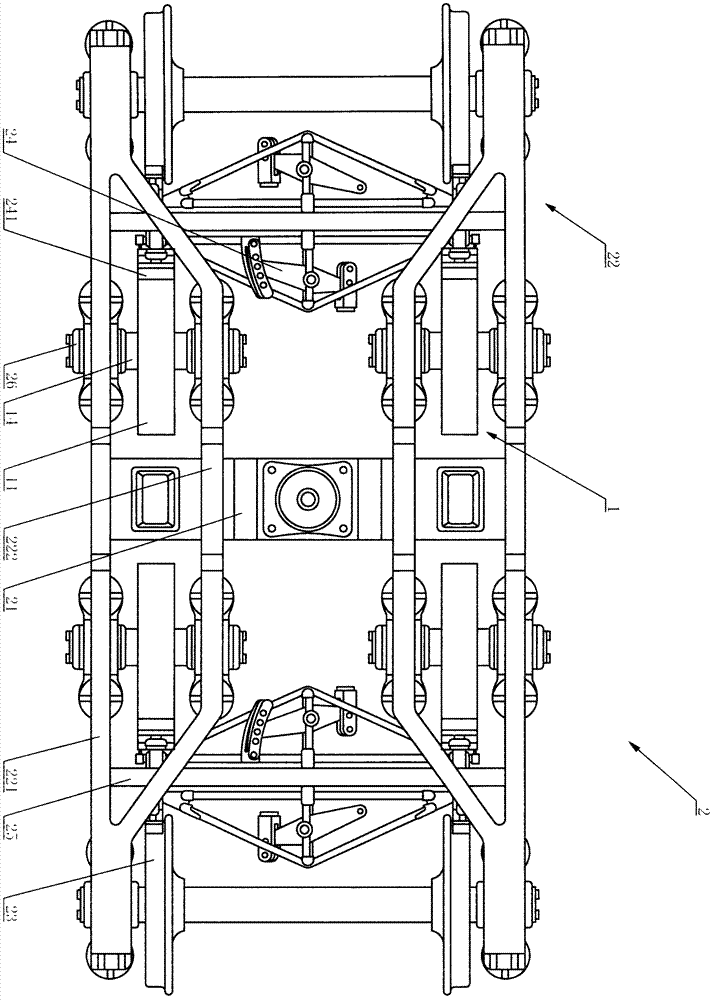

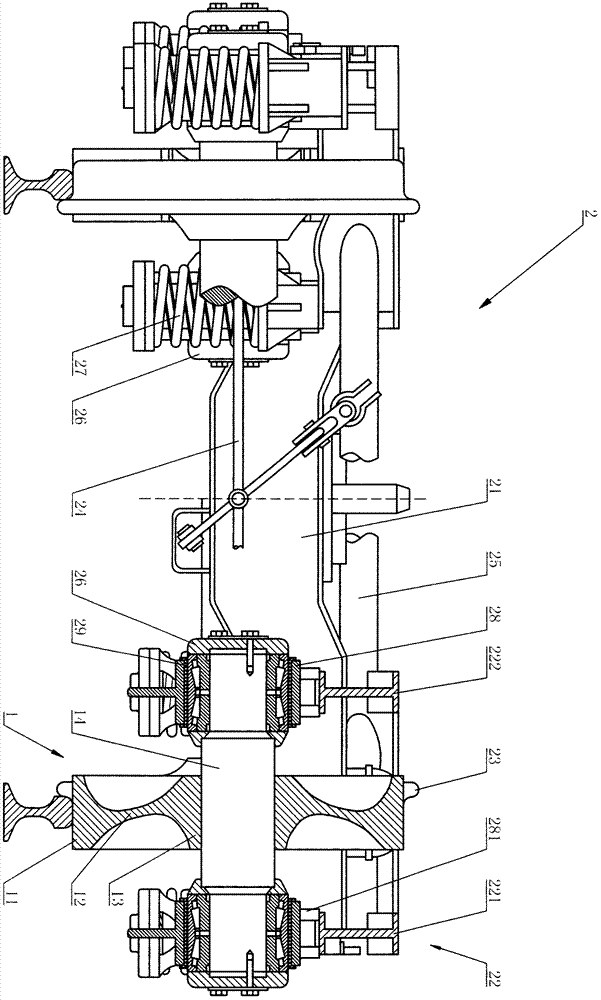

[0029] refer to figure 1 As shown, a bogie 2 of a railway heavy-duty truck vehicle in a preferred embodiment of the present invention includes a central beam 21, side frames 22 symmetrically connected to the two ends of the central beam 21, and symmetrically arranged on both sides of the side frames through the wheels. The wheel pair 23 at the end also includes at least one pair of track wheels 1 located between the wheel sets 23, the track wheels 1 are arranged on the side frames 23, and the track wheels 1 are as follows.

[0030] Also refer to figure 2 , image 3 As shown, the supporting wheel 1 includes an integrated rim 11, web 12 and hub 13; no rim is provided on the outer wheel surface of the rim 11, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com