Saddle-ride type vehicle

A ride-on vehicle and vehicle body technology, which is applied in the field of frame improvement, can solve the problems of driver maneuverability and changes in straightness, and achieve the effects of improving operability and straightness, improving efficiency, and suppressing deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be described below based on the drawings. In the drawings used below, arrow FR indicates the front of the vehicle, arrow UP indicates the upper side of the vehicle, and arrow LH indicates the left side of the vehicle.

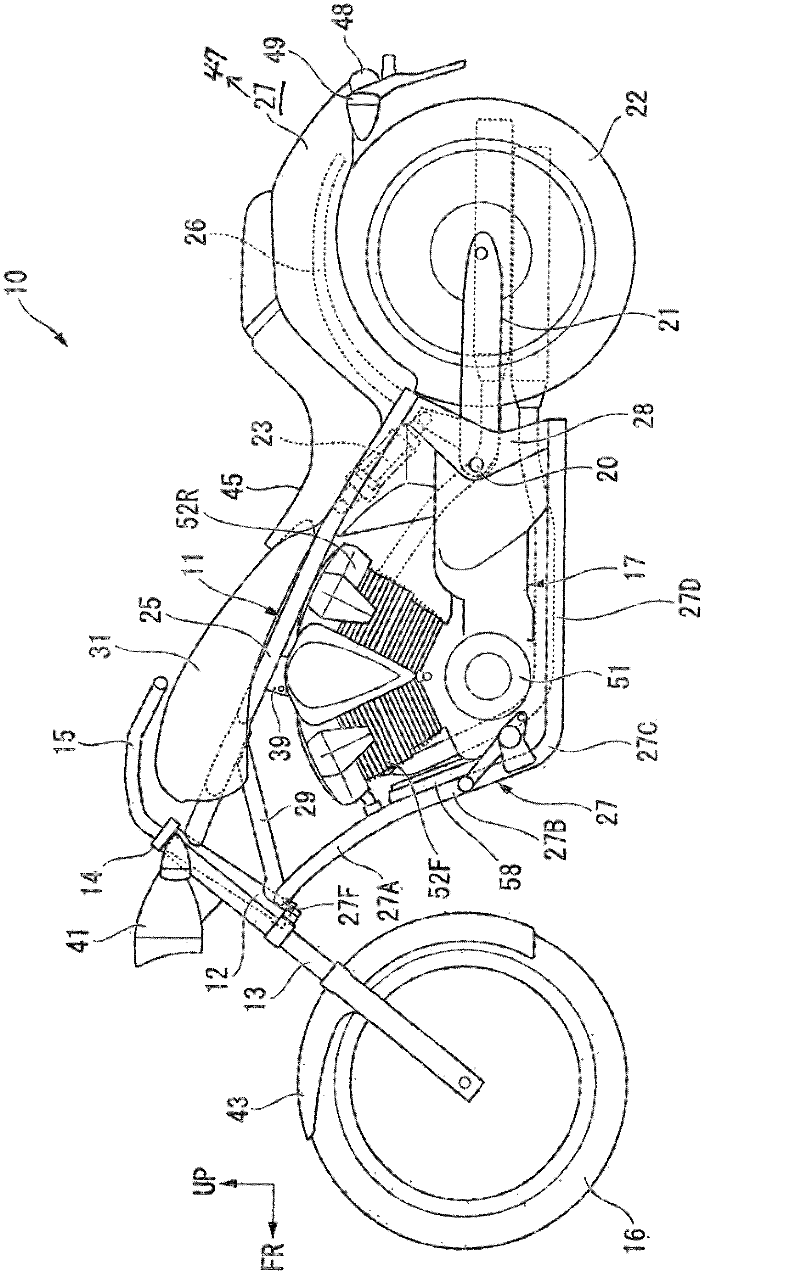

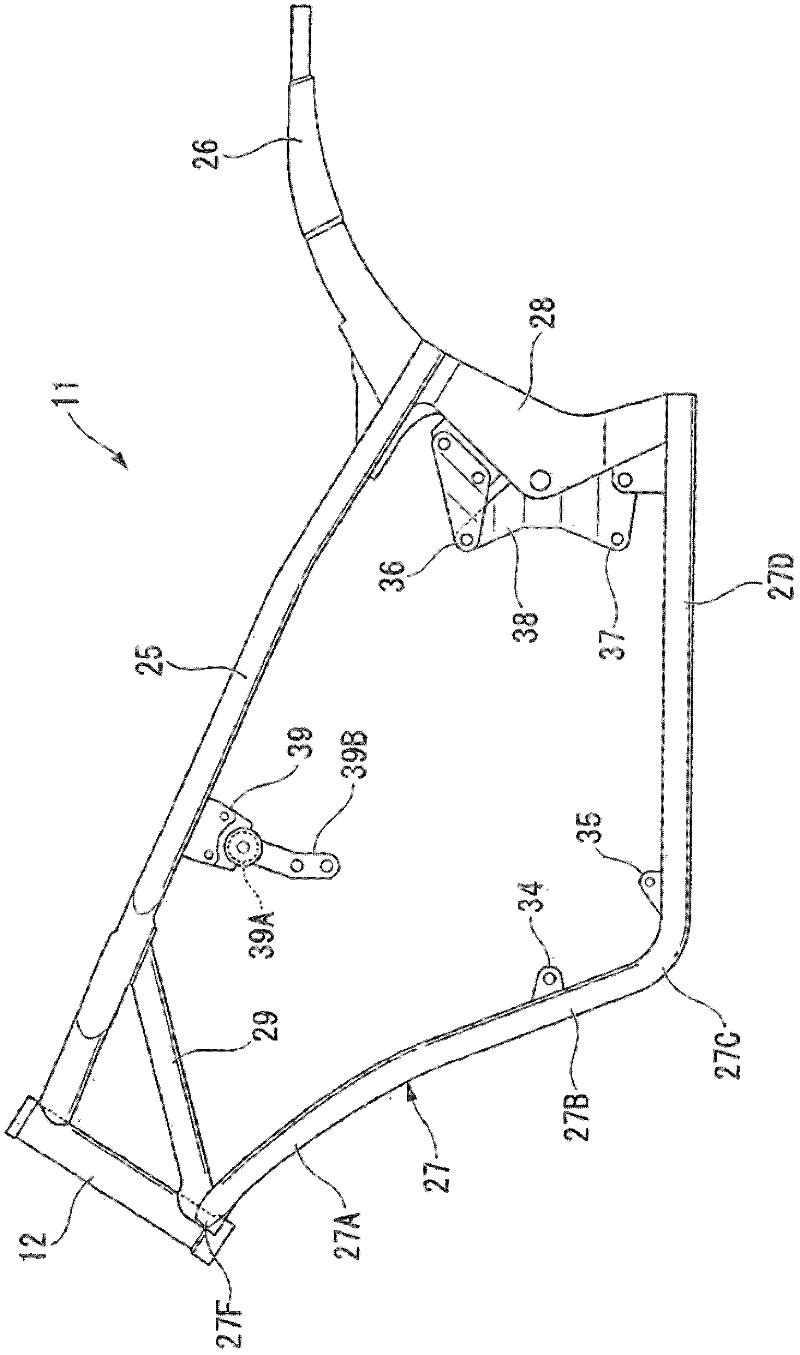

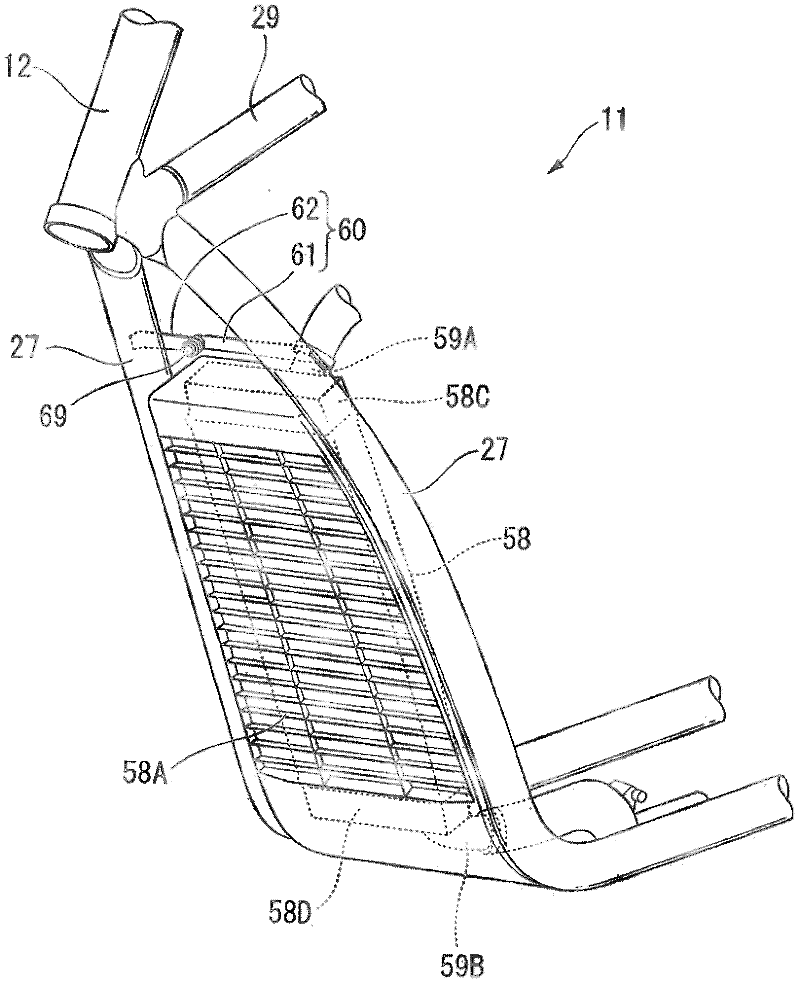

[0039] like figure 1 As shown, the two-wheeled motor vehicle 10 is a medium-sized (クル-ザ-ザタィプ) two-wheeled motor vehicle, and has: a vehicle body frame 11, a front fork 13 rotatably supported on a front pipe 12 mounted on the front end of the vehicle body frame 11, A steering handle 15 mounted on a top bridge (top bridge) 14 supported on the upper end of the front fork 13, a front wheel 16 rotatably supported on the front fork 13, and an engine (power engine) supported on the vehicle body frame 11. unit) 17, the rear rocker arm 21 supported on the pivot shaft 20 at the rear lower part of the vehicle body frame 11 to swing freely up and down, the rear wheel (drive wheel) 22 freely rotatably supported on the rear e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com