Modified casein, leather finishing agent and preparation method thereof

A technology of leather finishing agent and casein, which is applied in leather surface treatment, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc. It can solve the problems affecting the quality of leather finishing, Insufficient adhesion, easy peeling of the coating, etc., to achieve strong adhesion, stable product quality, and improved leather grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

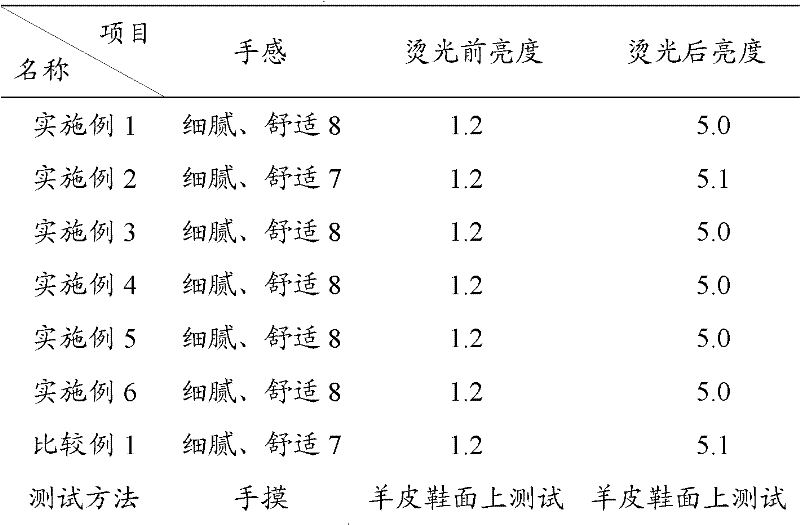

Examples

preparation example Construction

[0052] The invention provides a kind of preparation method of leather finishing agent, comprises the following steps:

[0053] a) dissolving casein and organic acid in water to obtain casein aqueous solution;

[0054] b) adding caprolactam to the aqueous casein solution obtained in the step a), and reacting to obtain an intermediate product;

[0055] c) adding a preservative to the intermediate product obtained in the step b), and stirring to obtain a leather finishing agent.

[0056] The invention uses caprolactam as a modifying agent to undergo graft polycondensation reaction with casein under the condition of dissolving casein with organic acid to directly obtain cationic casein leather finishing agent. The preparation method provided by the invention is simple and convenient, easy to produce in batches, and has stable product quality.

[0057] The present invention first dissolves casein and organic acid in water, so that casein is completely dissolved in water under org...

Embodiment 1

[0089] Weigh the following raw materials respectively:

[0090] 300g boiling water, 50g casein, 8g propionic acid, 30g caprolactam, 0.48g BIOBAN TM I-20 Antimicrobial and 0.64g BIOBAN TM ULTRA BIT 20 Antimicrobial;

[0091] Cool 20% of the total amount of boiling water to 60°C, add all the caprolactam to dissolve it, and obtain an aqueous solution of caprolactam;

[0092] Cool 5% of the total amount of boiling water to 60°C, add all BIOBAN TM I-20 Antimicrobial makes it all dissolve, obtains the first preservative aqueous solution;

[0093] Cool 5% of the total amount of boiling water to 60°C, add all BIOBAN TM ULTRA BIT 20 Antimicrobial is used to dissolve it completely to obtain the second preservative aqueous solution;

[0094] Add 70% of the total amount of boiling water into the reaction kettle, start stirring, add all the casein, and heat to 70°C to 75°C, and stir for 1 hour; add all the propionic acid into the reaction kettle, stir for 2 hours, and make the cas...

Embodiment 2

[0097] Weigh the following raw materials respectively:

[0098] 300g boiling water, 50g casein, 8g lactic acid, 0.45gV50, 32g caprolactam, 0.48gBIOBAN TM I-20 Antimicrobial and 0.64g BIOBAN TM ULTRA BIT 20 Antimicrobial;

[0099] Cool 25% of the total amount of boiling water to 55°C, add all the V50 to dissolve it, and obtain an aqueous initiator solution;

[0100] Cool 10% of the total amount of boiling water to 55°C, add all the caprolactam to dissolve it completely, and obtain an aqueous solution of caprolactam;

[0101] Cool 2% of the total amount of boiling water to 55°C and add all BIOBAN TM I-20 Antimicrobial makes it all dissolve, obtains the first preservative aqueous solution;

[0102] Cool 3% of the total amount of boiling water to 55°C and add all BIOBAN TM ULTRA BIT 20 Antimicrobial is used to dissolve it completely to obtain the second preservative aqueous solution;

[0103] Add 60% of the total amount of boiling water into the reaction kettle, start sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com