Walnut oil production method

A production method and technology of walnut oil, which are applied in the directions of fat oil/fat production, fat production, edible oil/fat, etc., can solve the problems of complex process and large nutritional damage of raw materials, and achieve simple process, natural oily smell, fragrance, nutrition and the like. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

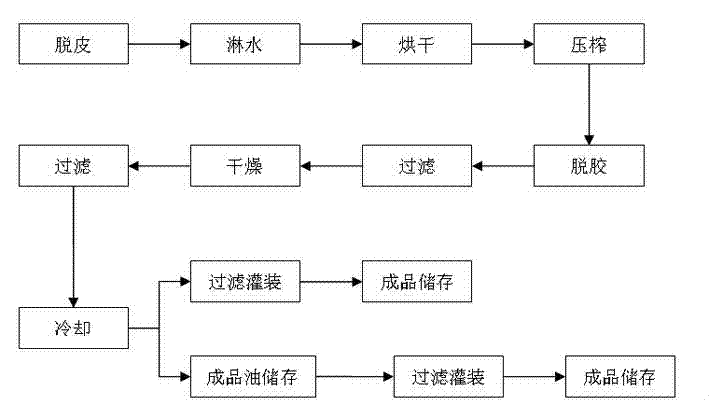

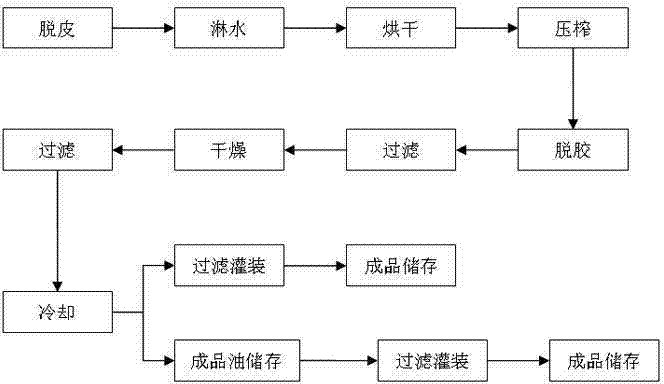

[0024] Such as figure 1 Shown, a kind of walnut oil production method of the present invention comprises the following steps:

[0025] (1) Peeling

[0026] Add the walnut kernels to be peeled into hot water at a temperature of 80°C (or 75°C or 85°C), soak for 10-15 minutes, drain the hot water, and use a water gun to draw cool water to rinse the walnut kernels in the jacketed pot to remove the attached Skin. The specific method is:

[0027] Add cold water into the stainless steel jacketed pot, the amount of water added is about one-third of the capacity of the stainless steel jacketed pot, open the steam valve, and adjust the steam pressure to below 0.1Mpa through the steam pressure reducing valve, which does not exceed the working pressure requirement of the jacketed pot. Heat the water in the stainless steel jacketed pot to 80°C (or 75°C or 85°C). Pour an appropriate amount of walnut kernels to be peeled into a stainless steel interlayer pot. It is advisable to su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com