Fermented grain long-fermentation-period flavor enhancement method for strong flavor Chinese spirit

A technology for strong-flavor liquor and fermented grains, which is applied in the field of winemaking, can solve problems such as poor extraction effect, and achieve the effects of reducing processing costs, improving liquor quality, and having broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1 Using the method of the present invention to increase the aroma of Luzhou-flavor distiller's grains during the long fermentation period

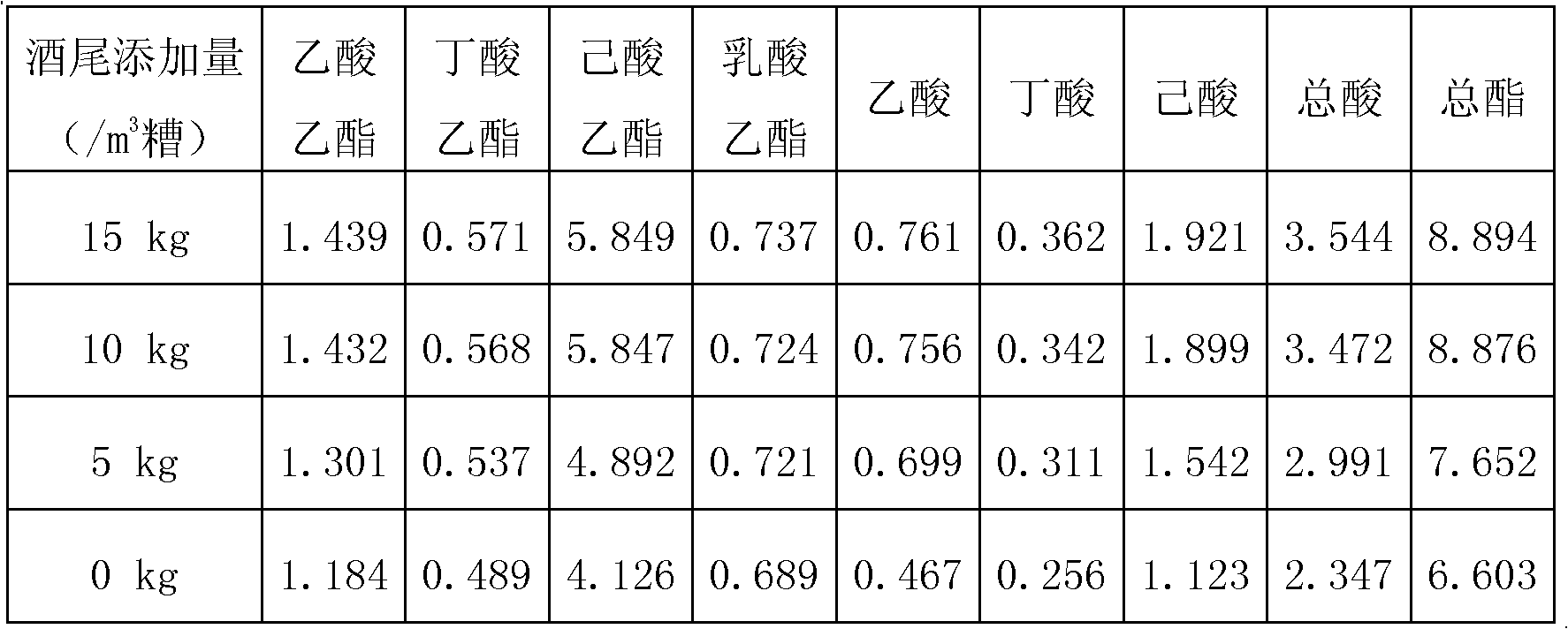

[0020] After 30 days of fermentation, Luzhou-flavored distiller's grains have a total of 4 cellars, and each cellar is added with 10kg / m of medium and high temperature koji 3 Poor, 60°slag wine 30kg / m 3 Poor, yellow water 10kg / m 3 Worse, mix evenly, and fill into the cellar. At the same time, at 15kg / m 3 Poor, 10kg / m 3 Poor, 5kg / m 3 Poor, 0kg / m 3 Distiller's tail (alcohol content is about 20°), decibels are added to 4 cellars for fermentation, and the fermentation time is 270 days. The contents of various aroma components in the wine produced from distilled grains were detected, and the results are shown in Table 1.

[0021] Table 1 Effects of different wine tail additions on the aroma components of fermented grains during long-growing period (unit: g / L)

[0022]

[0023] It can be seen from Table 1 that the amoun...

Embodiment 2

[0024] Example 2 Using the method of the present invention to increase the aroma of Luzhou-flavor distiller's grains during the long fermentation period

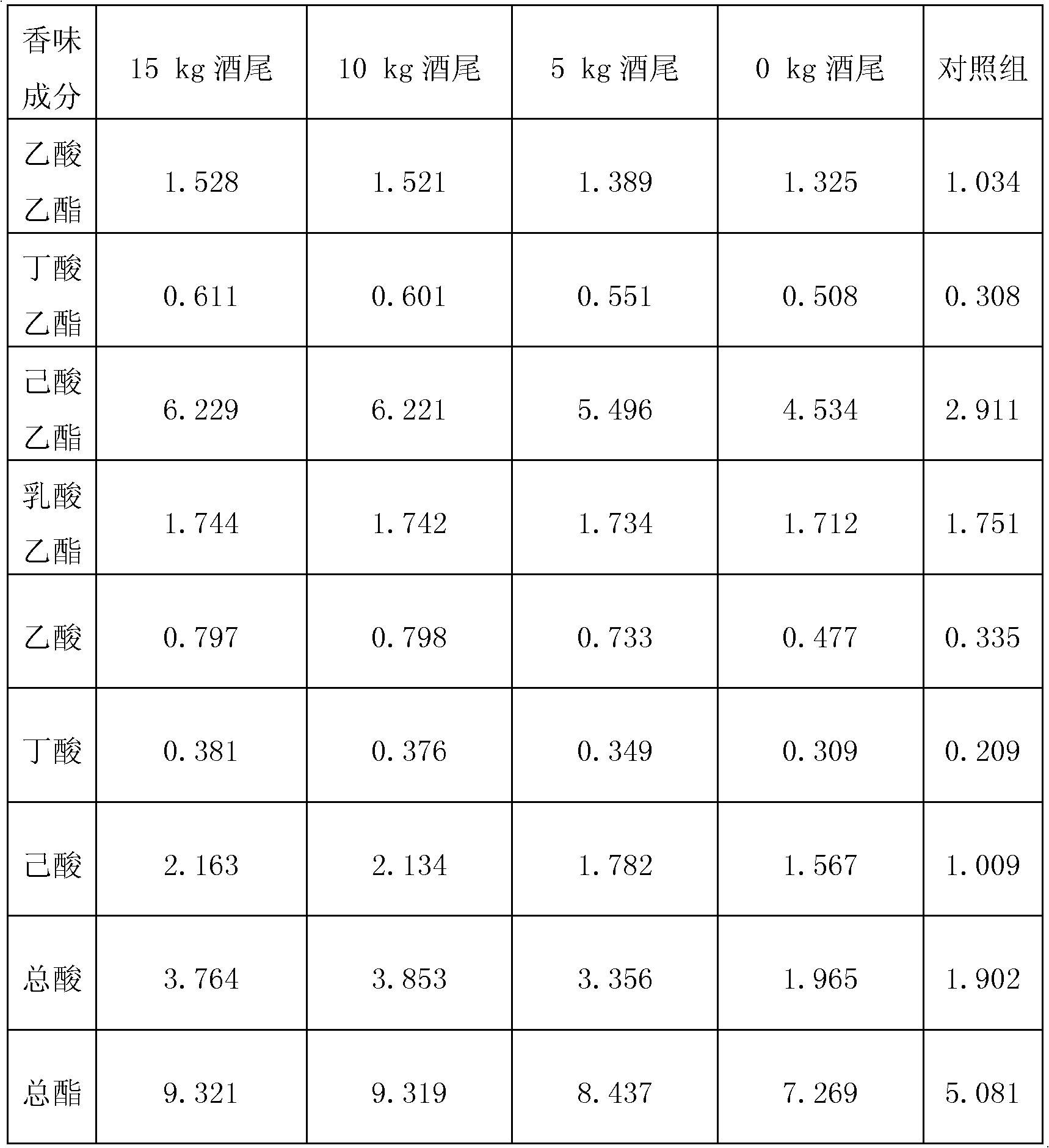

[0025] After 30 days of fermentation, Luzhou-flavored distiller's grains have a total of 4 cellars, and each cellar is added with 10kg / m of medium and high temperature koji 3 Poor, 60°slag wine 30kg / m 3 Poor, yellow water 10kg / m 3 Worse, mix evenly, and fill into the cellar. At the same time, at 15kg / m 3 Poor, 10kg / m 3 Poor, 5kg / m 3 Poor, 0kg / m 3 Distiller's tail (alcohol content is about 20°), decibels are added to 4 cellars, and fermented for 150 days. Then, take out the fermented grains in the cellar respectively, and add 5 kg / m of medium and high temperature koji 3 Mix well, and add wine tail (alcohol content about 20°) 5kg / m into the grains 3 Poor, sprinkle evenly, fill in the cellar, and ferment again for 120 days.

[0026] In addition, a control group is set up. The fermented grains in the control group are n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com