Coating liquid and heating non-burning smoke core material

A technology for coating liquid and tobacco, which is applied in the fields of tobacco, processed tobacco, essential oils/spices, etc. It can solve the problems of atomization loss and other problems, and achieve the effect of increasing the proportion of aroma substances, not easy to stick and agglomerate, and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

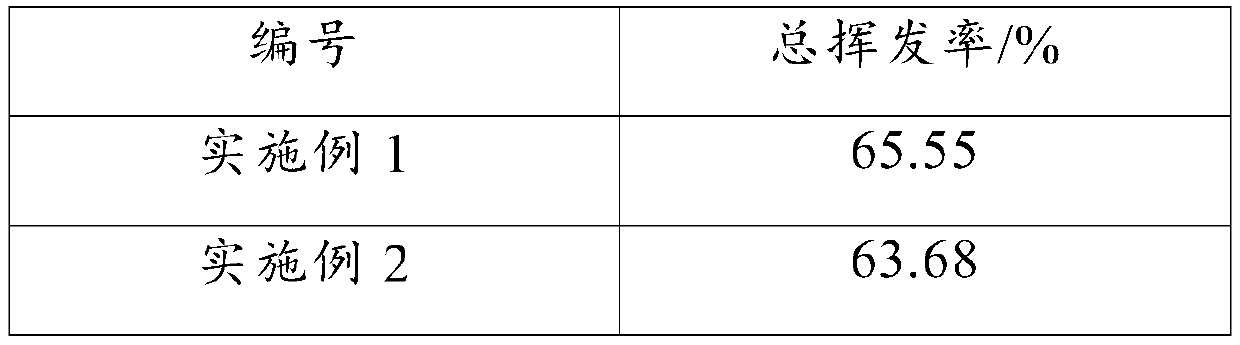

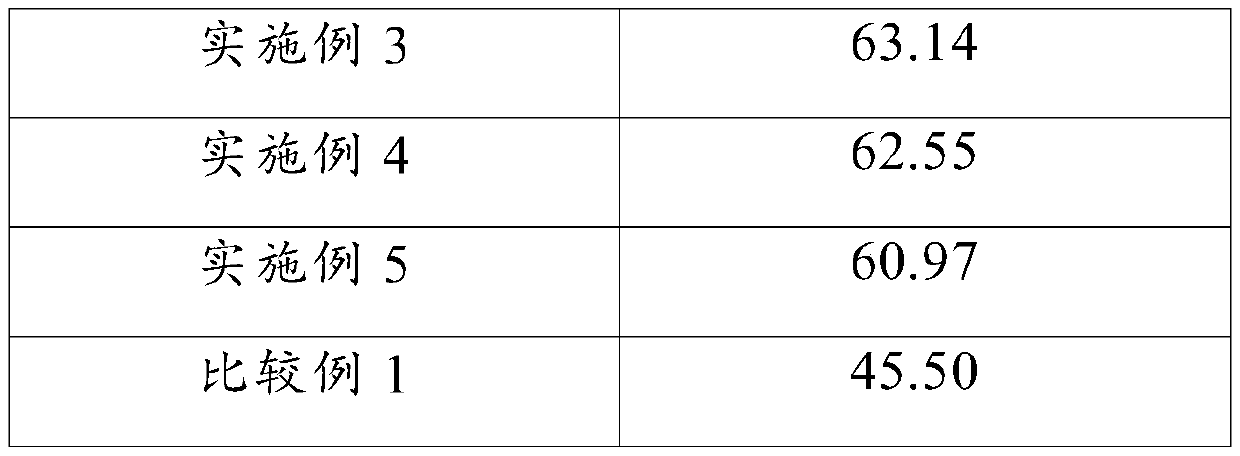

Embodiment 1

[0048] Glycerin is used as a fuming agent, absolute ethanol is used as a co-solvent, and the extraction solvent is obtained by configuring the mass ratio of the fuming agent to the co-solvent at 1:9.

[0049] The extraction equipment adopts continuous ultrasonic extraction equipment, and adopts three-stage countercurrent extraction.

[0050]Prepare materials according to the mass ratio of extraction solvent to tobacco raw material of 7:1, heat up the extraction solvent to 60°C, and then add the first batch of tobacco raw materials into the first-stage extraction tank, keep warm at 60°C for 25 minutes, separate solid-liquid, solid-form The material is sent to the second-stage extraction tank, the extraction solvent is supplemented so that the mass ratio of the extraction solvent to the solid is maintained at 7:1, the heat preservation is carried out at 60°C for 25 minutes, the solid-liquid is separated, and the liquid is sent back to the first-stage extraction tank and the secon...

Embodiment 2

[0055] A mixture of glycerin and propylene glycol (mass ratio 9:1) is used as a fuming agent, a mixture of water and ethanol (mass ratio 6:4) is used as a co-solvent, and the extraction is obtained according to the mass ratio of the fuming agent and the co-solvent of 7:3. solvent.

[0056] The extraction equipment adopts continuous ultrasonic extraction equipment, and adopts three-stage countercurrent extraction.

[0057] The tobacco leaf raw material is taken, and the tobacco raw material is obtained through impurity removal, uniform mixing and refining.

[0058] Prepare materials according to the mass ratio of extraction solvent to tobacco raw material of 5:1, raise the temperature of the extraction solvent to 70°C, then add the first batch of tobacco raw materials into the first-stage extraction tank, heat at 70°C for 20 minutes, separate solid-liquid, solid-form The material is sent to the second-stage extraction tank, the extraction solvent is supplemented so that the ma...

Embodiment 3

[0063] Glycerin is used as a fuming agent, and a mixture of water, ethanol and Tween-80 is used as a co-solvent, wherein the mass ratio of water to ethanol is 4:6, and the amount of Tween-80 is 0.3% of the mass of the co-solvent. The mass ratio of agent and co-solvent is 2:8 to configure the extraction solvent.

[0064] The extraction equipment adopts continuous ultrasonic extraction equipment, and adopts three-stage countercurrent extraction.

[0065] The tobacco leaf raw material is taken, and the tobacco raw material is obtained through impurity removal, uniform mixing and refining.

[0066] Prepare materials according to the mass ratio of extraction solvent to tobacco raw material of 12:1, raise the temperature of extraction solvent to 37°C, and then add it to the first-stage extraction tank together with the first batch of tobacco raw materials, keep warm at 37°C for extraction for 50 minutes, separate solid and liquid, and solidify The material is sent to the second-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com