Processing method for improving fragrance of middle-grade and low-grade tea leaves and tea products prepared by processing method

A processing method, medium and low-grade technology, applied in the direction of tea treatment before extraction, etc., can solve the problems of poor aroma of medium and low-grade tea, achieve the effects of simple addition operation, easy control of various parameters, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

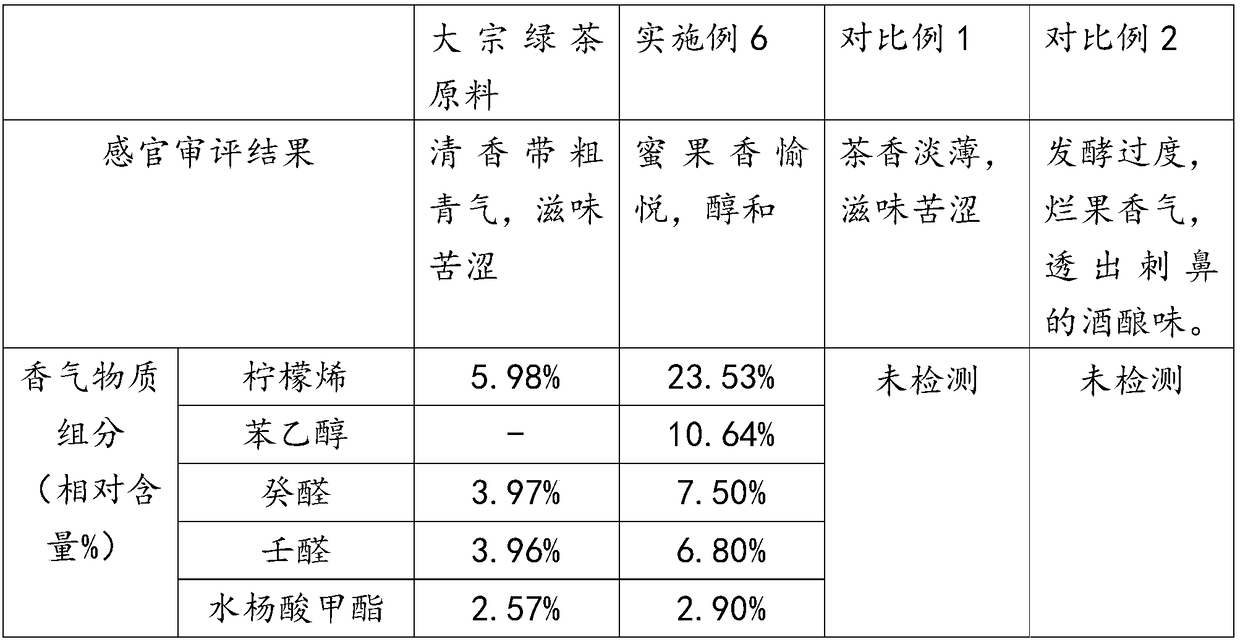

Embodiment 1

[0026] Take 200g Dianhong bar-shaped tea (mesh: 4-8 mesh) as tea raw material, weigh 20g white granulated sugar according to 10% of tea quality, weigh 2g of shellfish yeast according to 1% of tea quality, dissolve in 250g water to make No. The first-stage fermentation broth is soaked and stirred to make the Dianhong bar-shaped tea fully absorb water and regain moisture. Spread the tea leaves on trays and ferment for 18 hours in an aerobic environment at 10°C. After the first stage of fermentation is over, press shellfish yeast: Saccharomyces cerevisiae = 2:1, weigh 1g of Saccharomyces cerevisiae, dissolve it in 20g of pure water to prepare the second stage fermentation liquid, mix it with the first stage fermented tea leaves and pour it into the fermentation In the barrel, pile up to 20cm high, seal the mouth of the barrel with a food-grade plastic film, and ferment for 12 hours in a sealed anaerobic environment at 30°C. After the two-stage fermentation, use an electric blast...

Embodiment 2

[0028] Weigh 200g Dianhong bar-shaped tea (mesh: 4-8 mesh) as tea raw material, weigh 20g white granulated sugar according to 10% of tea quality, weigh 2g of Torulasporum dell’s yeast according to 1% of tea quality, dissolve in 250g water The first-stage fermentation broth is made, and the Dianhong bar-shaped tea is soaked and stirred to make it fully absorb water and regain moisture. Spread the tea leaves on trays and ferment for 18 hours in an aerobic environment at 10°C. After the first stage of fermentation is over, according to Torula dell’s spores: Saccharomyces cerevisiae = 2:1, weigh 1g of Saccharomyces cerevisiae, dissolve it in 20g of pure water to prepare the second stage fermentation liquid, and fully mix it with the first stage fermented tea leaves Pour it into a fermenter, pile it up to 20cm high, seal the mouth of the barrel with a food-grade plastic film, and ferment for 12 hours in a sealed anaerobic environment at 30°C. After the two-stage fermentation, use ...

Embodiment 3

[0030]Weigh 200g Dianhong bar-shaped tea (mesh: 4-8 mesh) as tea raw material, weigh 20g white granulated sugar according to 10% of tea quality, weigh 2g of Hansenula spp. according to 1% of tea quality, dissolve in 250g water The first-stage fermentation broth is made, and the Dianhong bar-shaped tea is soaked and stirred to make it fully absorb water and regain moisture. Spread the tea leaves on trays and ferment for 18 hours in an aerobic environment at 10°C. After the first stage of fermentation is over, according to Hansen’s spores: Saccharomyces cerevisiae = 2:1, weigh 1g of Saccharomyces cerevisiae, dissolve it in 20g of pure water to prepare the second stage of fermentation liquid, and fully mix it with the first stage of fermented tea leaves Pour it into a fermenter, pile it up to 20cm high, seal the mouth of the barrel with a food-grade plastic film, and ferment for 12 hours in a sealed anaerobic environment at 30°C. After the two-stage fermentation, use an electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com