Method for treating pot bottom water through low-cost anaerobic fermentation

A technology of anaerobic fermentation and bottom pot water, which is applied in fermentation, biochemical equipment and methods, and recovery of by-products, etc., can solve the problems of ineffective utilization of organic matter in bottom pot water, difficulty in bottom pot water treatment, and high processing cost. Achieve the effects of overcoming economic losses and water pollution, increasing the content of main flavor components, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for treating bottom pot water by low-cost anaerobic fermentation, comprising the following steps:

[0024] (1) Filter the bottom pot water stock solution through gauze, then add 4 times the mass of deionized water to dilute, adjust the pH value to 5, and obtain the fermentation broth;

[0025] (2) Put the fermented liquid obtained in step (1) into a fermenter, add 15g / L pit mud containing anaerobic microorganisms (butyric acid bacteria, caproic acid bacteria), and cultivate it at a temperature of 30°C for 7 days to complete the bottom pot water deal with. The fermenter is equipped with a safety valve with a pressure value of 0.2kPa; when the fermentation gas exceeds 0.2kPa, the fermenter will reduce the pressure through the safety valve and let the nutrients in the tank be automatically mixed through the air pressure difference.

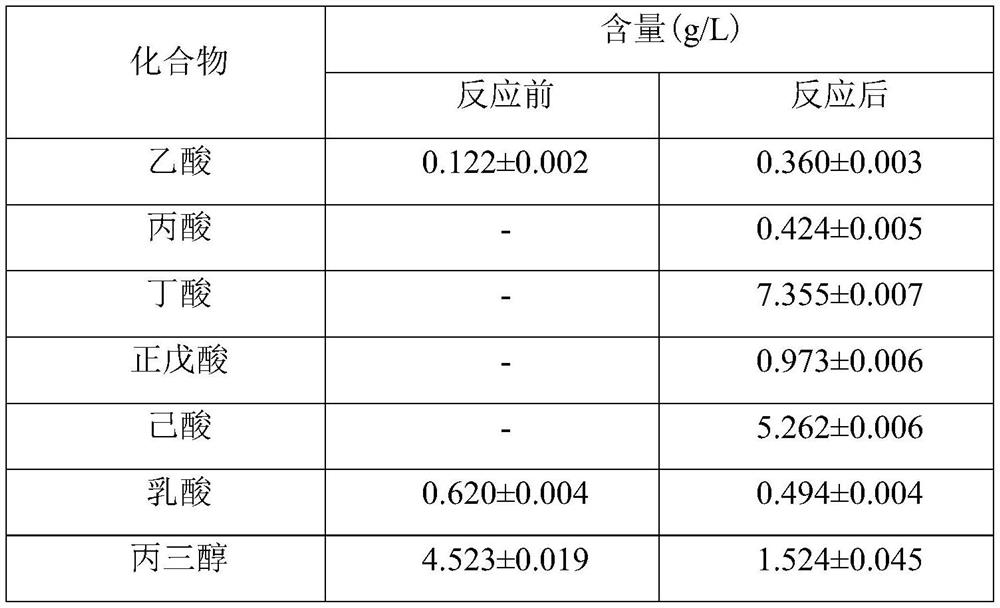

[0026] The finished liquid after the final fermentation was completed was qualitatively and quantitatively analyzed by Headspace So...

Embodiment 2

[0035] A method for treating bottom pot water by low-cost anaerobic fermentation, comprising the following steps:

[0036] (1) Filter the bottom pot water stock solution through gauze, then add 5 times the mass of deionized water to dilute, adjust the pH value to 5.3, and obtain the fermentation broth;

[0037] (2) Put the fermented liquid obtained in step (1) into a fermenter, add 20g / L pit mud containing anaerobic microorganisms (butyric acid bacteria, caproic acid bacteria), and cultivate it at 35°C for 10 days to complete the bottom pot water deal with. The fermenter is equipped with a safety valve with a pressure value of 0.2kPa; when the fermentation gas exceeds 0.2kPa, the fermenter will reduce the pressure through the safety valve and let the nutrients in the tank be automatically mixed through the air pressure difference.

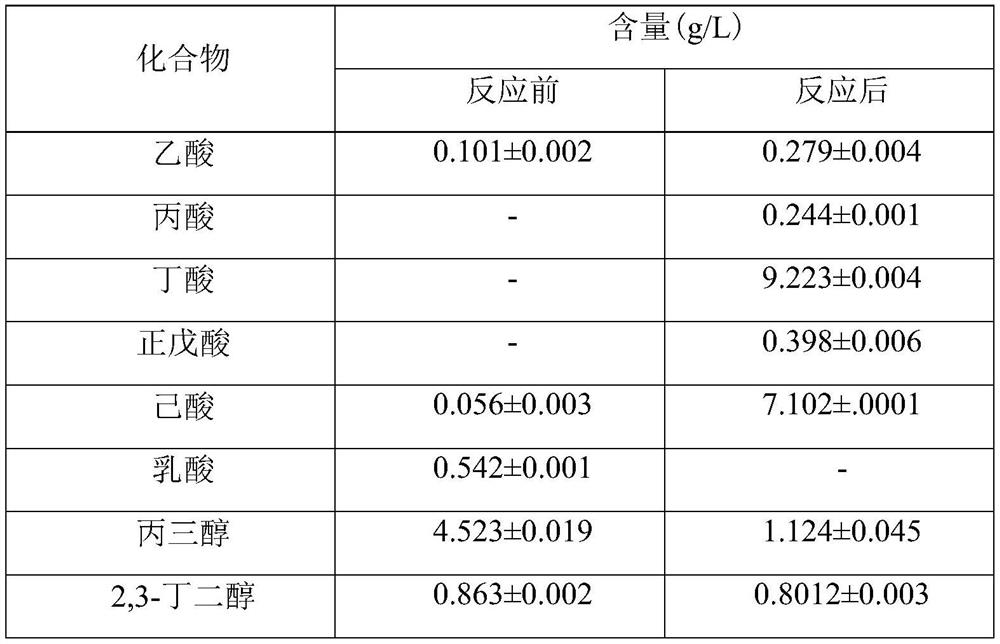

[0038] The finished liquid after the final fermentation was completed was qualitatively and quantitatively analyzed by Headspace Solid Phase Micr...

Embodiment 3

[0045] A method for treating bottom pot water by low-cost anaerobic fermentation, comprising the following steps:

[0046] (1) Filter the bottom pot water stock solution through gauze, then add 6 times the mass of deionized water to dilute, adjust the pH value to 5.5, and obtain the fermentation broth;

[0047](2) Put the fermented liquid obtained in step (1) into a fermenter, add 25g / L pit mud containing anaerobic microorganisms (butyric acid bacteria, caproic acid bacteria), and cultivate it at a temperature of 45°C for 15 days to complete the bottom pot water deal with. The fermenter is equipped with a safety valve with a pressure value of 0.2kPa; when the fermentation gas exceeds 0.2kPa, the fermenter will reduce the pressure through the safety valve and let the nutrients in the tank be automatically mixed through the air pressure difference.

[0048] The finished liquid after the final fermentation was completed was qualitatively and quantitatively analyzed by Headspace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com